Oil gas water three phase on-line inseparate flow measurement system

A flow measurement, oil-gas-water technology, applied in the direction of fluid velocity measurement, measurement, measurement devices, etc., can solve the problems of large oil-water density difference, large gas-oil ratio, and difficulty in taking oil-water mixed samples, so as to ensure accuracy and avoid The effect of water channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation methods, Structure, characteristic and effect thereof are as follows in detail.

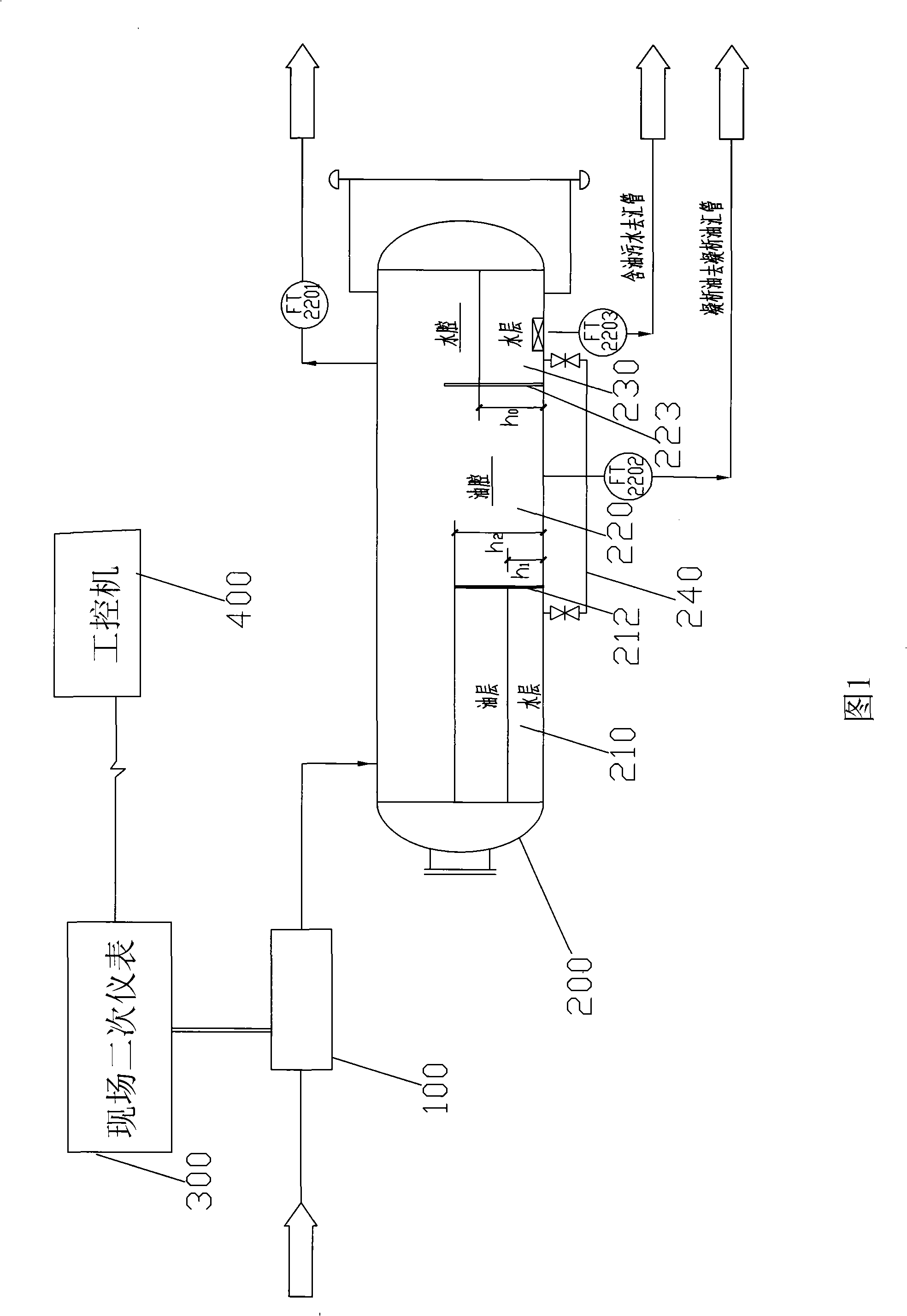

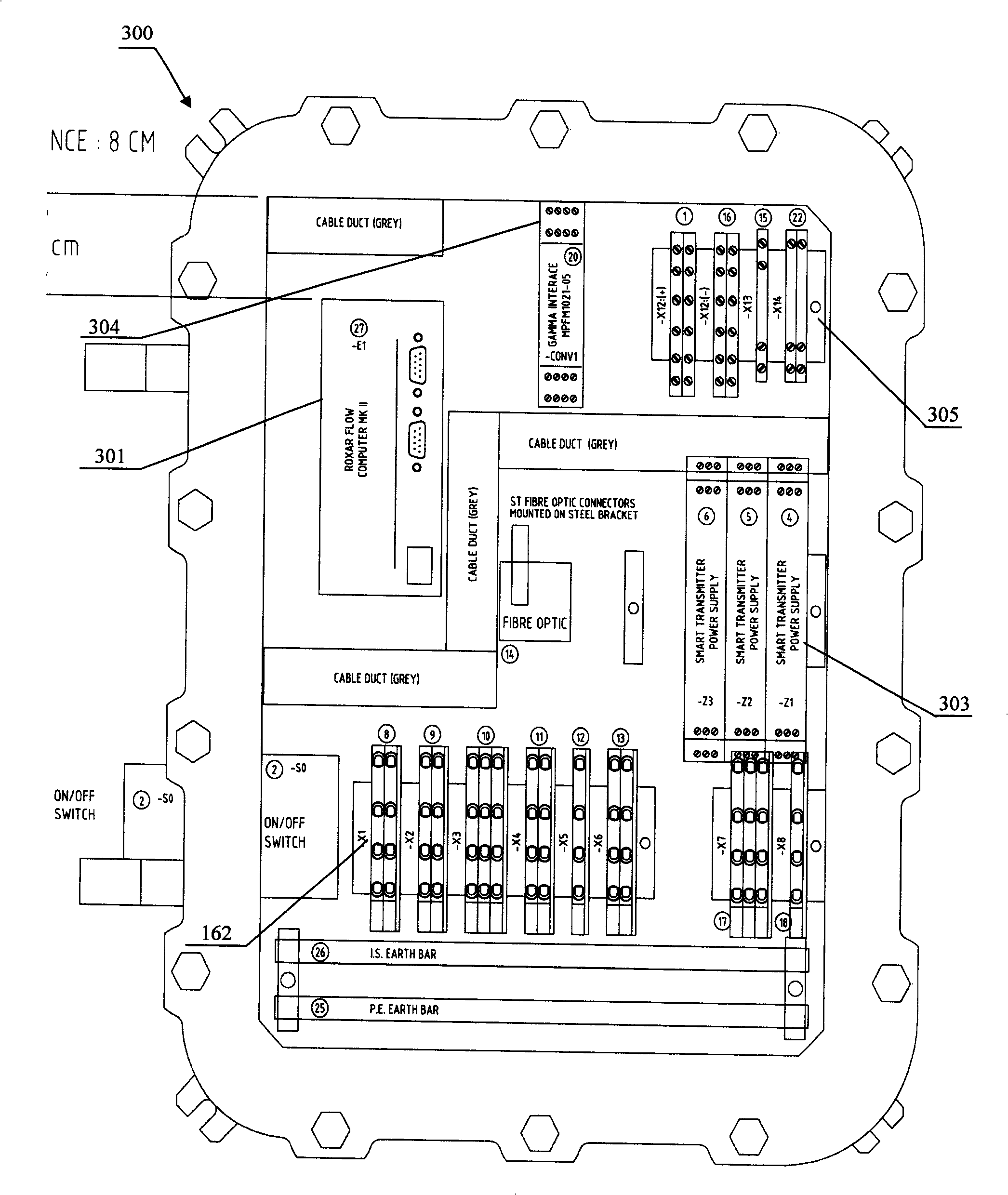

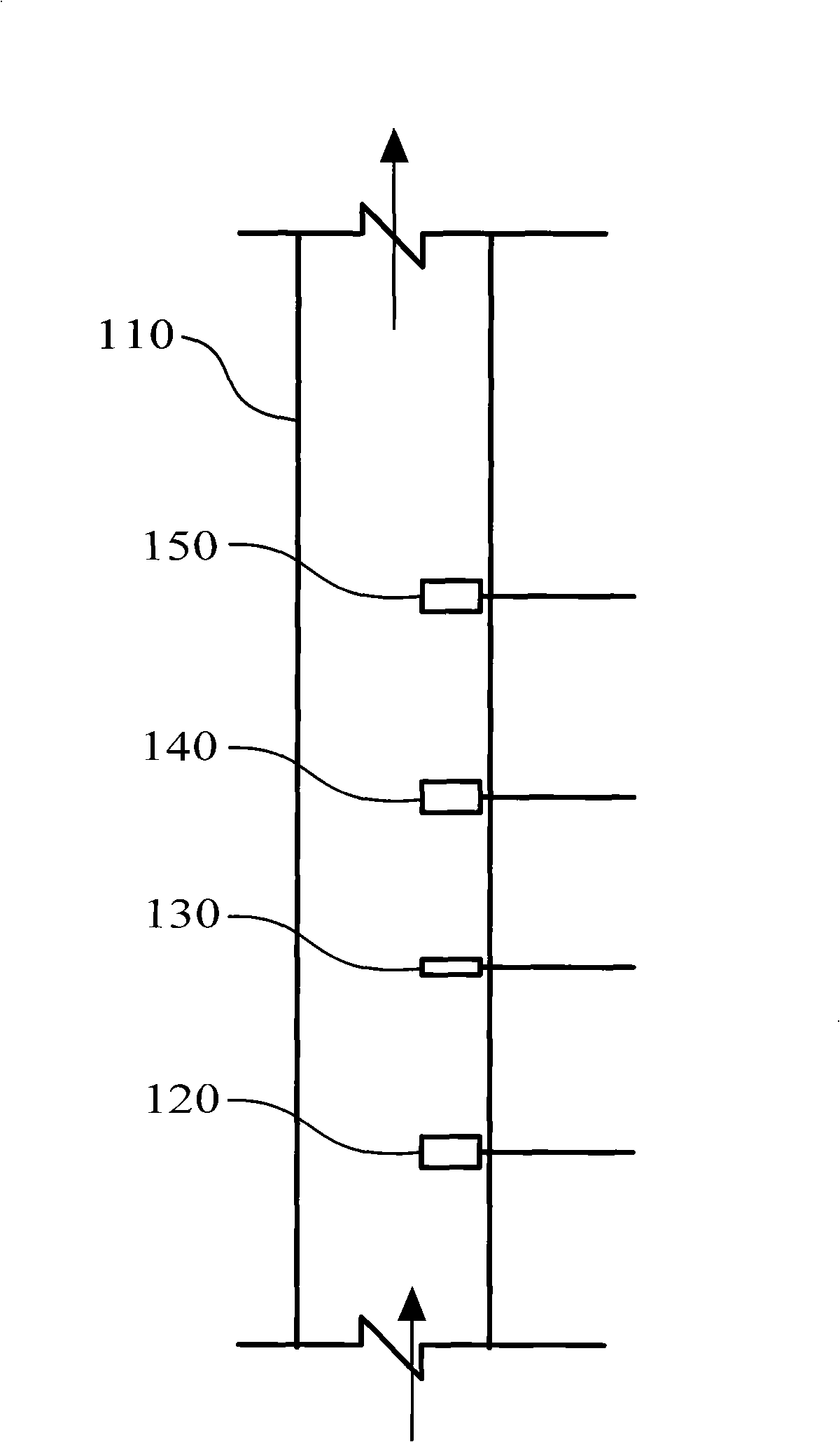

[0028] Please refer to FIG. 1 , which is a schematic flow diagram of an embodiment of the oil-gas-water three-phase on-line non-separated flow measurement system of the present invention. The oil-gas-water three-phase online non-separated flow measurement system is used to measure the flow of oil, gas and water in a single well, which includes: a three-phase non-separated flowmeter 100 , an on-site secondary instrument 300 and an industrial computer 400 . The inlet of the three-phase non-separated flowmeter 100 is connected to a single well oil-gas-water mixture pipeline for real-time measurement of the flow of oil, water and gas in the oil-water-gas mixture. The on-site secondary instrument 300 is connected to the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com