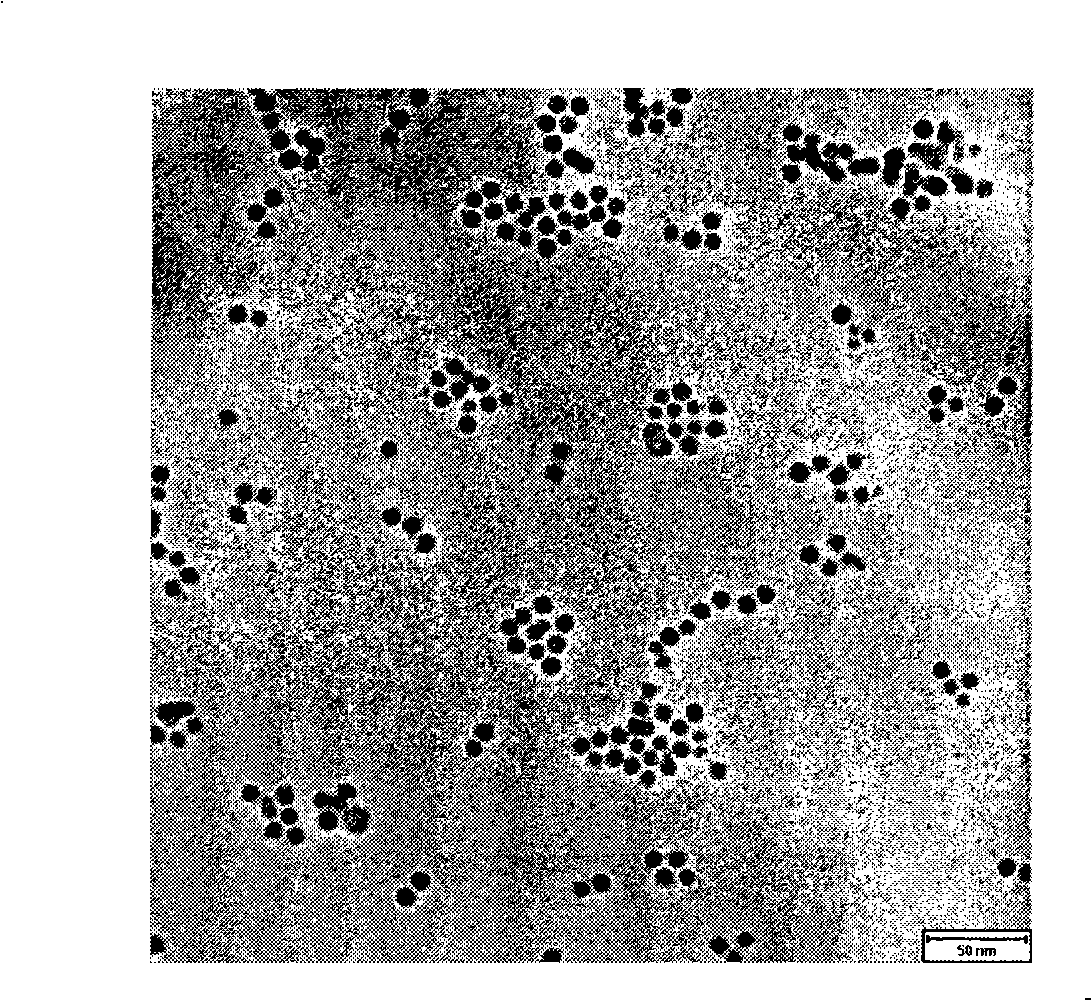

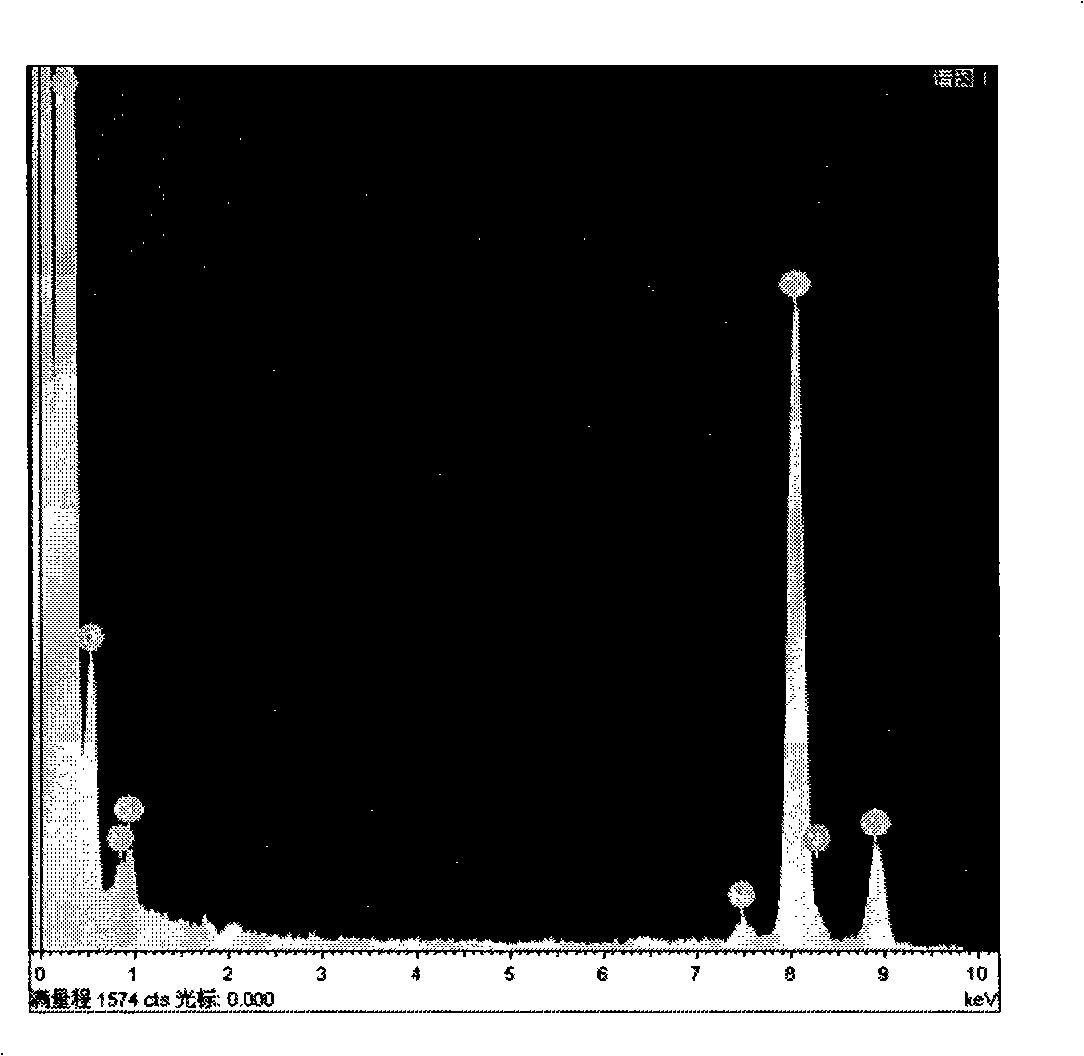

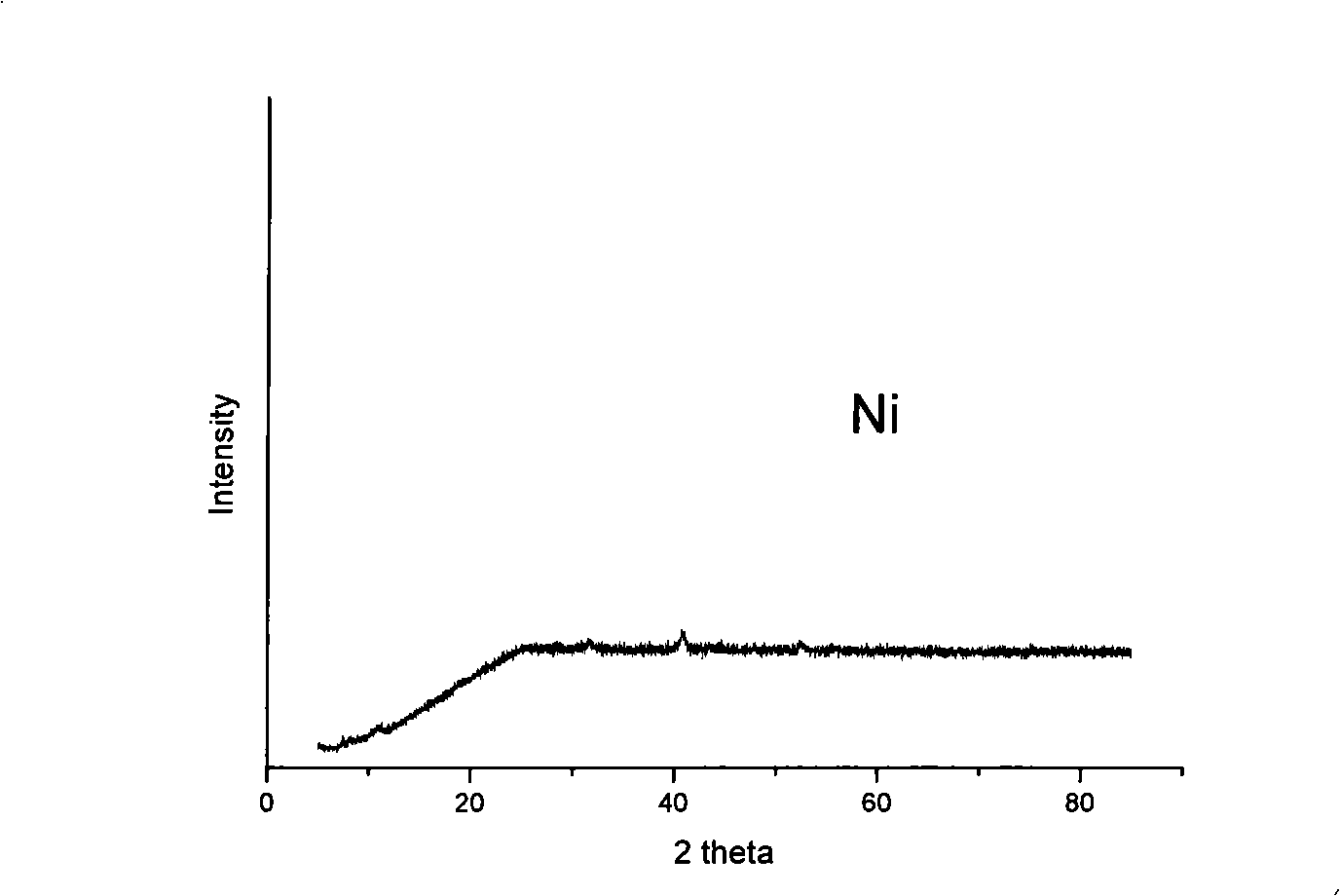

Preparation and separation method of monodisperse amorphous state nickel nano particle

A nanoparticle and amorphous nickel technology, which is applied in the field of preparation and separation of monodisperse amorphous nickel nanoparticles, can solve the problems of toxic nickel carbonyl, low decomposition temperature, and detachment of stabilizer molecules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical characteristics of the present invention will be described in detail below in conjunction with the embodiments.

[0022] In actual preparation, the method of the present invention is realized in the laboratory like this:

[0023] Put 2mmol nickel acetylacetonate, 6ml trioctylphosphine, 6ml oleylamine, 2mmol 1,2-hexadecanoyl alcohol, 1% organic iron (relative to the quality of nickel acetylacetonate), and 40ml liquid paraffin into a 100ml stainless steel autoclave In the reactor, high-purity nitrogen gas is introduced to remove oxygen. Pass hydrogen gas (purity 99.9%) into the autoclave, fill the pressure to 4.0MPa, adjust the stirring speed to 500rpm, then raise the temperature to 300°C, and react for 3 hours. After the reaction was completed, the reactor was opened, and the reaction solution was taken out and placed in a 250 ml beaker. Add 40 milliliters of ethanol and 10 milliliters of petroleum ether (60-90° C.) into the beaker, stir well and place it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com