Process for preparing starch-based film by propionyl-starch-grafting polylactic acid

A technology for propionylating starch and starch base, which is applied in the field of modification and modification of natural polymer materials, can solve the problems of complex process flow and a large number of organic solvents, and achieves the effects of simple reaction process, reduced pollution and improved hydrophobic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

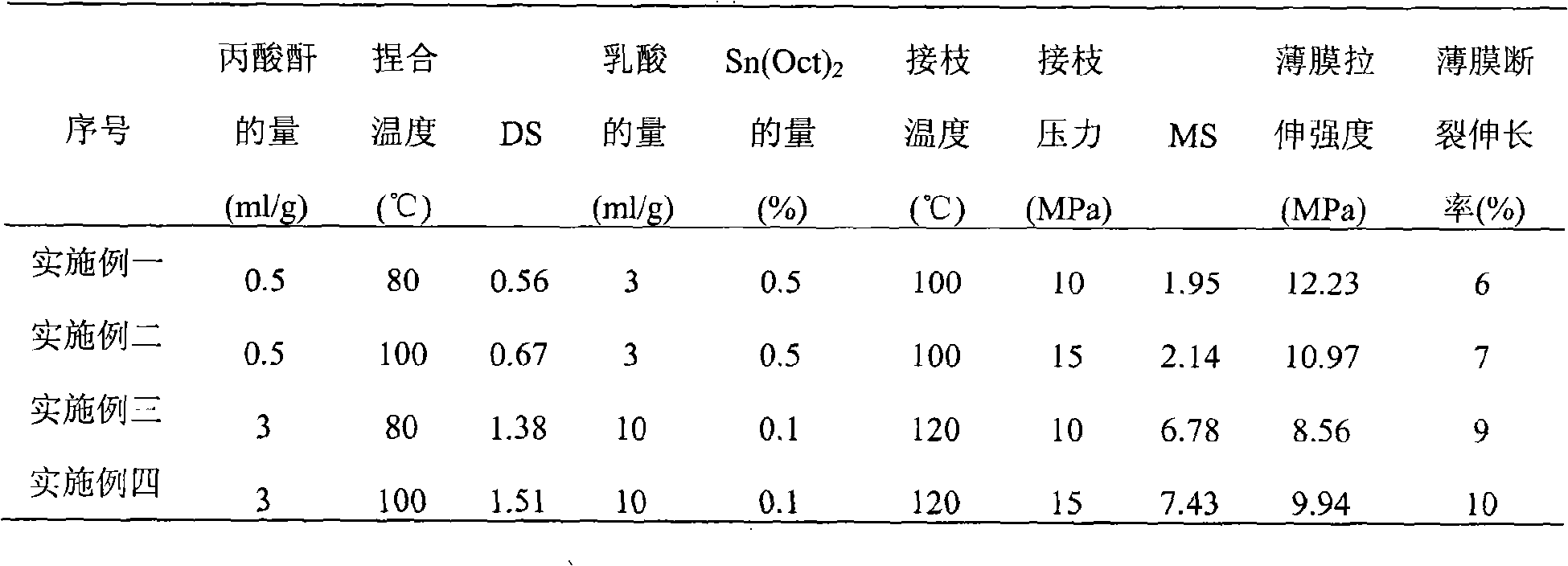

Embodiment 1

[0019] (1) Put starch with a water content of 20% in a kneader at a temperature of 80° C. and a rotating speed of 100 rpm. After mixing for 60 minutes, add 0.5 ml / g of propionic anhydride (calculated on the dry basis of starch) (shown in Table 1) to react After 30min, add 3ml / g of lactic acid (on starch dry basis) and a mass concentration of 0.5% Sn(Oct) 2 (Based on starch dry basis) (shown in Table 1), adjust the temperature of the reaction system to be 100°C and the pressure to be grafted for 10 hours under 10MPa; after the reaction is completed, dissolve in chloroform, precipitate with ethanol, filter, wash and dry The propionylated starch grafted polylactic acid copolymer was obtained. The propionyl substitution degree (DS) of starch molecules in propionylated starch grafted polylactic acid copolymer was 0.56, and the molecular substitution degree (MS) of polylactic acid was 1.95.

[0020] (2) Dissolve propionylated starch-grafted polylactic acid copolymer in acetone to f...

Embodiment 2

[0022] (1) Mix starch with a water content of 20% in a kneader at a temperature of 100° C. and a speed of 100 rpm for 60 minutes, then add 0.5 ml / g of propionic anhydride (calculated on the dry basis of starch) (as shown in Table 1) and react for 30 minutes Afterwards, add 3ml / g of lactic acid (in starch dry basis) and mass concentration be 0.5%Sn(Oct) 2 (Based on starch dry basis) (as shown in Table 1), adjust the temperature of the reaction system to be 100°C and the pressure to be grafted for 10 hours under 15MPa; after the reaction is completed, dissolve in chloroform, precipitate with ethanol, filter, wash and dry The propionylated starch grafted polylactic acid copolymer was obtained. The propionyl substitution degree (DS) of starch molecules in propionylated starch grafted polylactic acid copolymer was 0.67, and the molecular substitution degree (MS) of polylactic acid was 2.14.

[0023] (2) Dissolve propionylated starch-grafted polylactic acid copolymer in acetone to ...

Embodiment 3

[0025] (1) Mix starch with a water content of 20% in a kneader at a temperature of 80° C. and a rotation speed of 100 rpm for 60 minutes, then add 3 ml / g of propionic anhydride (calculated on the dry basis of starch) (as shown in Table 1) and react for 30 minutes. , adding 10ml / g of lactic acid (based on starch dry basis) and a mass concentration of 0.1% Sn(Oct) 2 (Based on starch dry basis) (shown in Table 1), adjust the temperature of the reaction system to be 120°C and the pressure to be grafted for 10 hours under 10MPa; after the reaction is completed, dissolve in chloroform, precipitate with ethanol, filter, wash and dry The propionylated starch grafted polylactic acid copolymer was obtained. The propionyl substitution degree (DS) of starch molecules in propionylated starch grafted polylactic acid copolymer was 1.38, and the molecular substitution degree (MS) of polylactic acid was 6.78.

[0026] (2) Dissolve propionylated starch-grafted polylactic acid copolymer in acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com