Double oil path vane pump /motor

A vane pump and double oil circuit technology, applied in pumps, pump components, machines/engines, etc., can solve the problems of vane pumps not working normally, limiting the range of use of vane pumps, working oil pressure can not be too high, etc., to achieve simple structure, Ease of assembly and small output torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

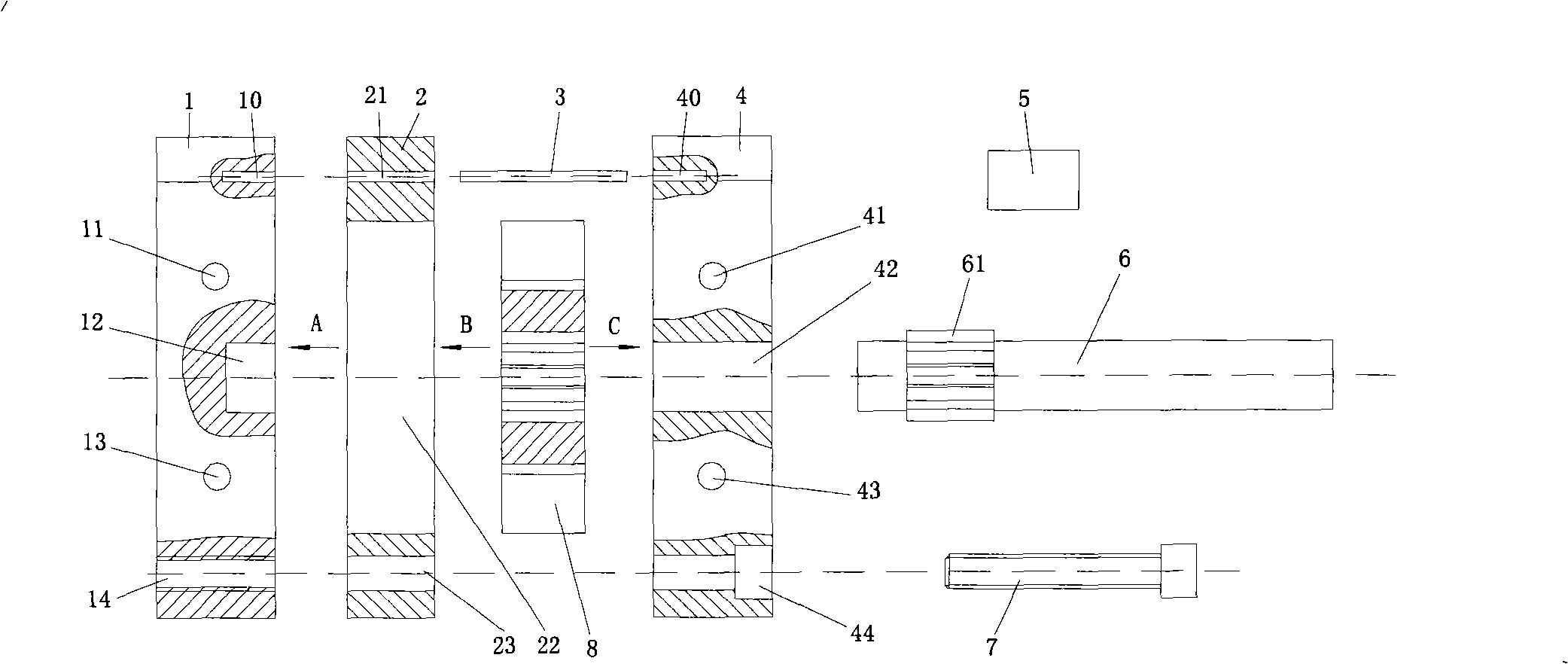

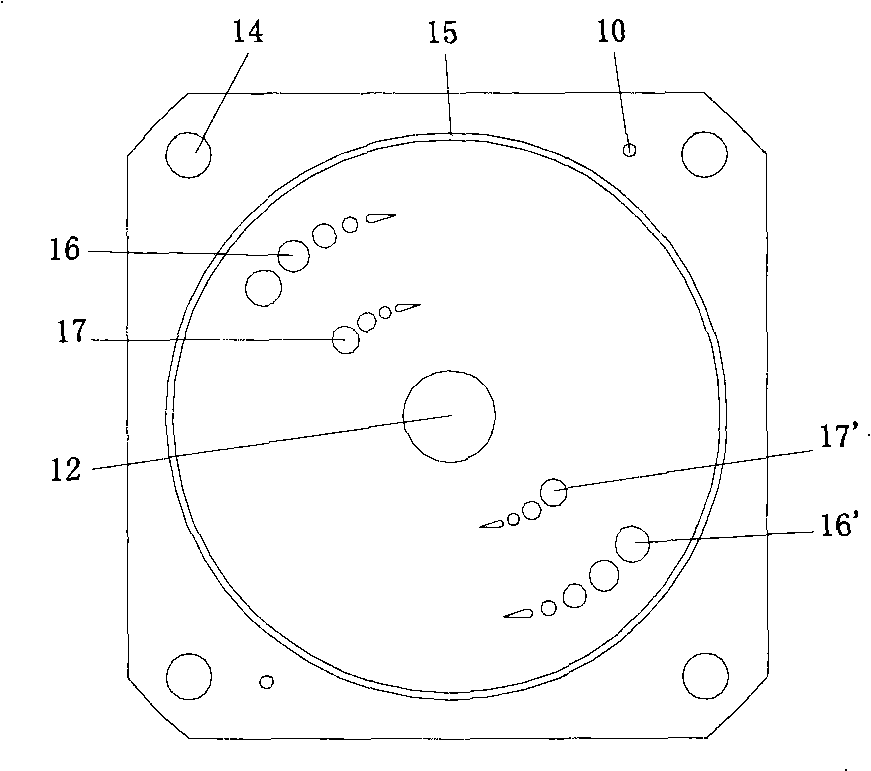

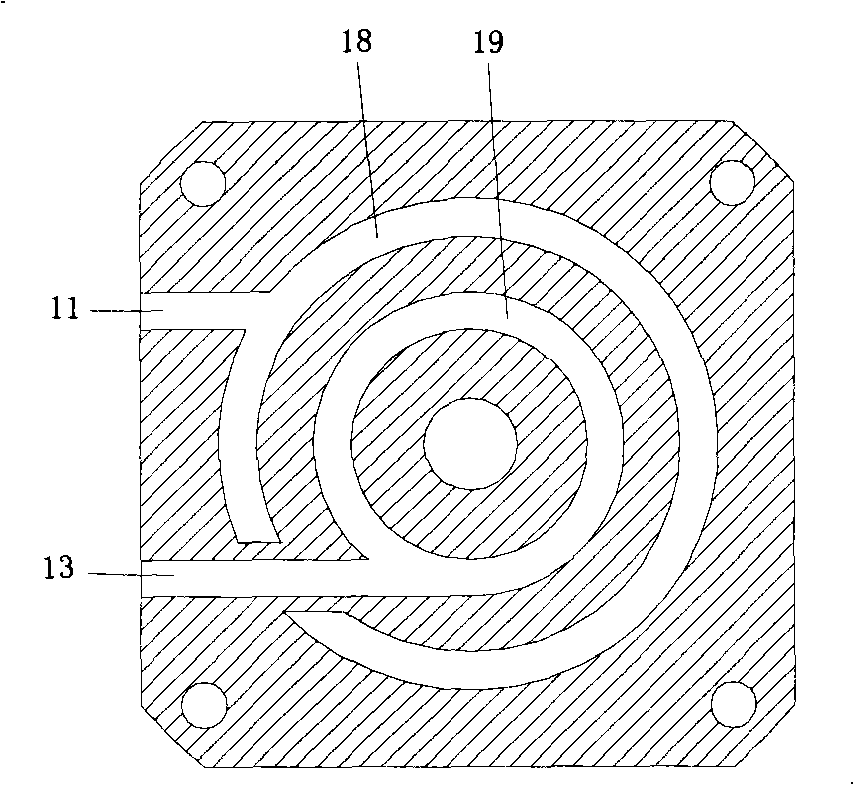

[0037] Such as figure 1 As shown, the vane pump or motor of the present invention includes a left end cover 1, a right end cover 4, a spindle 2, a rotor 8, blades 5, and a working shaft 6. The spindle 2 is clamped and fixed between the left and right end covers by screws 7, and the left and right end covers A sealing ring (not shown in the figure) is arranged on the connection surface with the spindle, see Figure 6 , Figure 7 , Figure 9, the rotor 8 is fitted in the inner cavity 22 of the spindle 2, the blades 5 are fitted in the blade grooves 81 of the rotor 8 one by one, and a positioning pin 3 is arranged between the left end cover 1, the right end cover 4 and the spindle 2, and the working The shaft 6 is fitted on the rotor 8 through its spline 61, the left end of the working shaft 6 is installed in the shaft hole 12 provided on the left end cover 1, and its right end is protruded through the shaft hole 42 on the right end cover 4 to connect with the external power. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com