Method for preparing white light LED utilizing YAG transparent ceramic

A technology of transparent ceramics and LED chips, which is applied to optical components, lighting and heating equipment, and components of lighting devices for changing the spectral characteristics of emitted light, can solve the problem of occupying large precious metals, complicated processes and high production costs. and other problems, to achieve the effect of low cost, simple process operation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

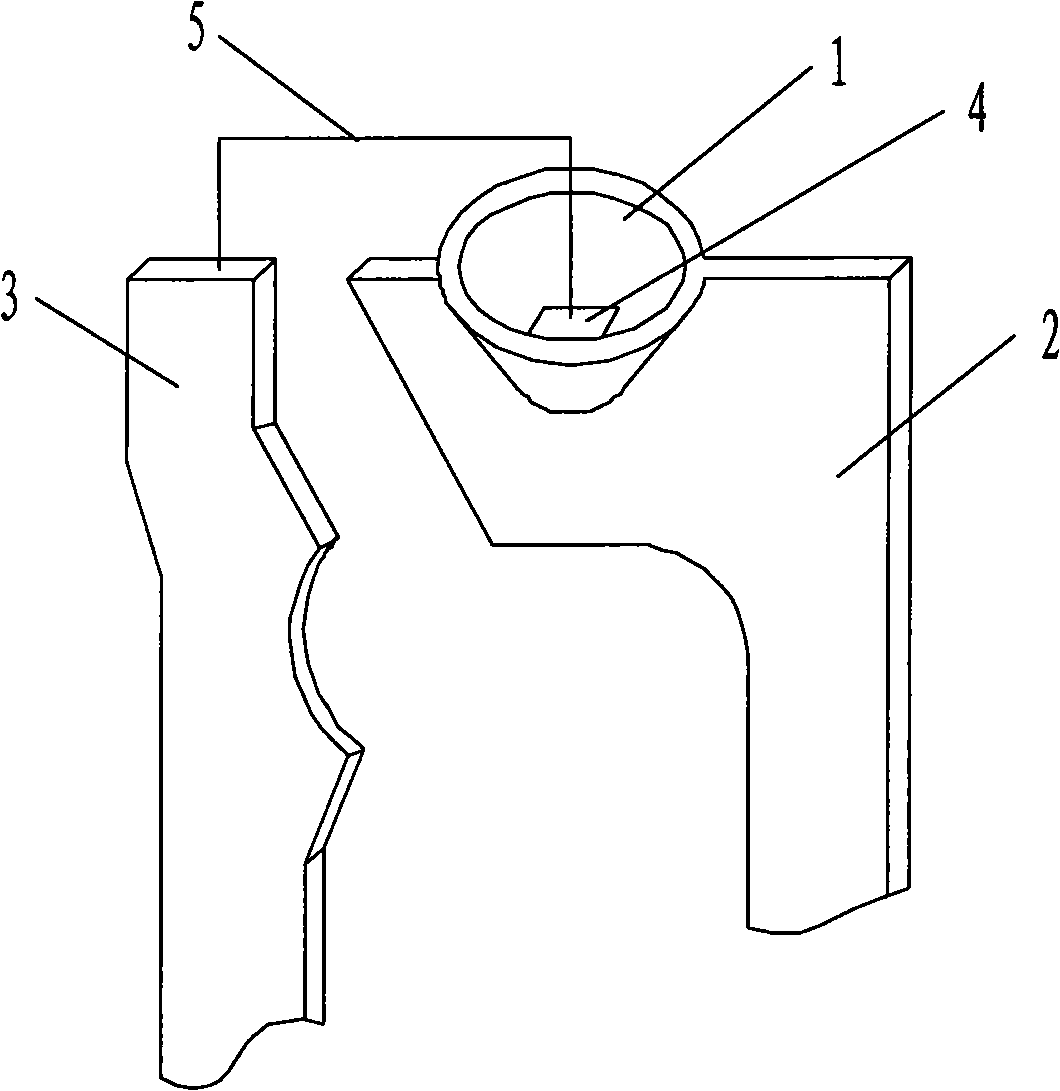

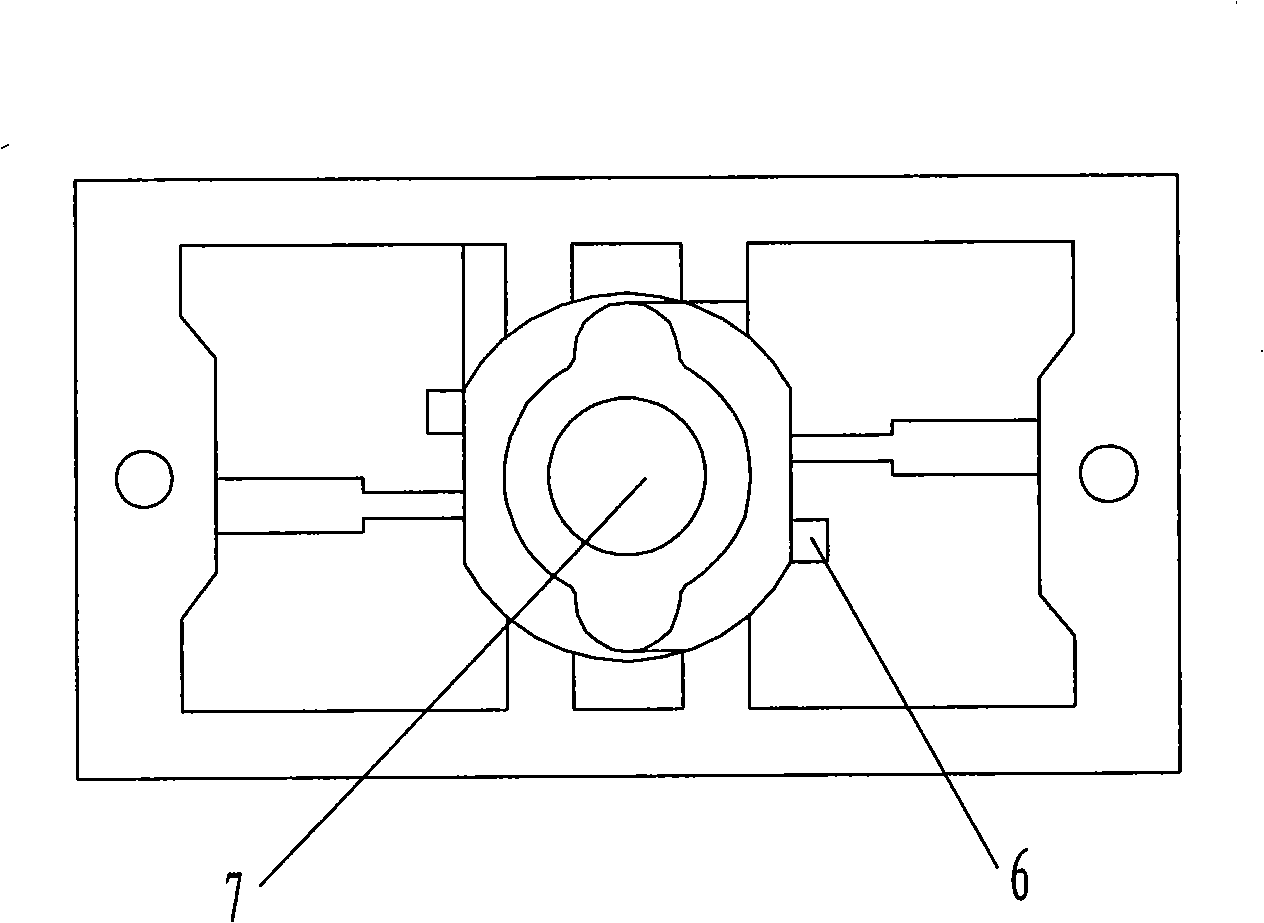

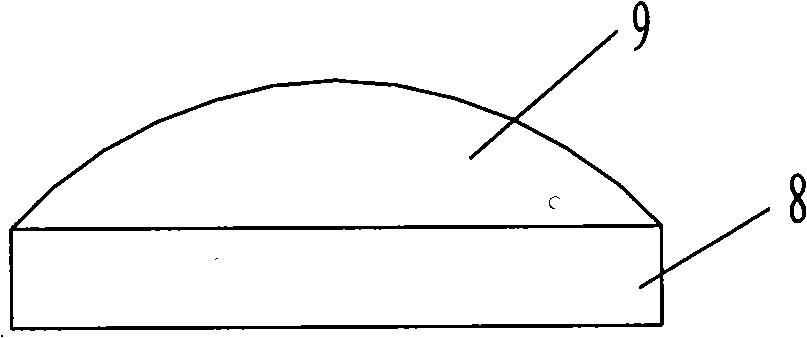

[0024] The present invention utilizes YAG transparent ceramics to prepare the method of white light LED is that the light of blue light or ultraviolet LED light-emitting chip absorbs part of the light of the light-emitting chip when passing through the YAG transparent ceramic material and converts it into light with a wavelength different from that of the light-emitting chip, and the light of different wavelengths is mixed to obtain white light. The required components or materials at least include blue or ultraviolet LED light-emitting chips, YAG transparent ceramics (ceramic layer), support reflectors and potting materials. The bracket mirror adopts a bowl-shaped reflective cup, and the potting material adopts transparent insulating glue such as silica gel, epoxy resin, and silicon dioxide. Such as figure 1 As shown, the exposed blue or ultraviolet LED chips 4 are first fixed to the bottom of the bowl-shaped reflective cup 1 with insulating glue. A low-power bowl-shaped re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com