Explosive stability nitrous oxides concentration detection device

A nitrogen oxide and concentration detection technology, which is applied in the direction of analysis by chemical reaction of materials and material analysis by observing the influence on chemical indicators, can solve the problem of balance damage of thermal decomposition of explosives and chemical reactions, which is difficult to accurately represent. The concentration of nitrogen oxides, slowing down the decomposition reaction, etc., to achieve the effect of reducing labor intensity, high accuracy, and reducing instantaneous pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the drawings and preferred embodiments.

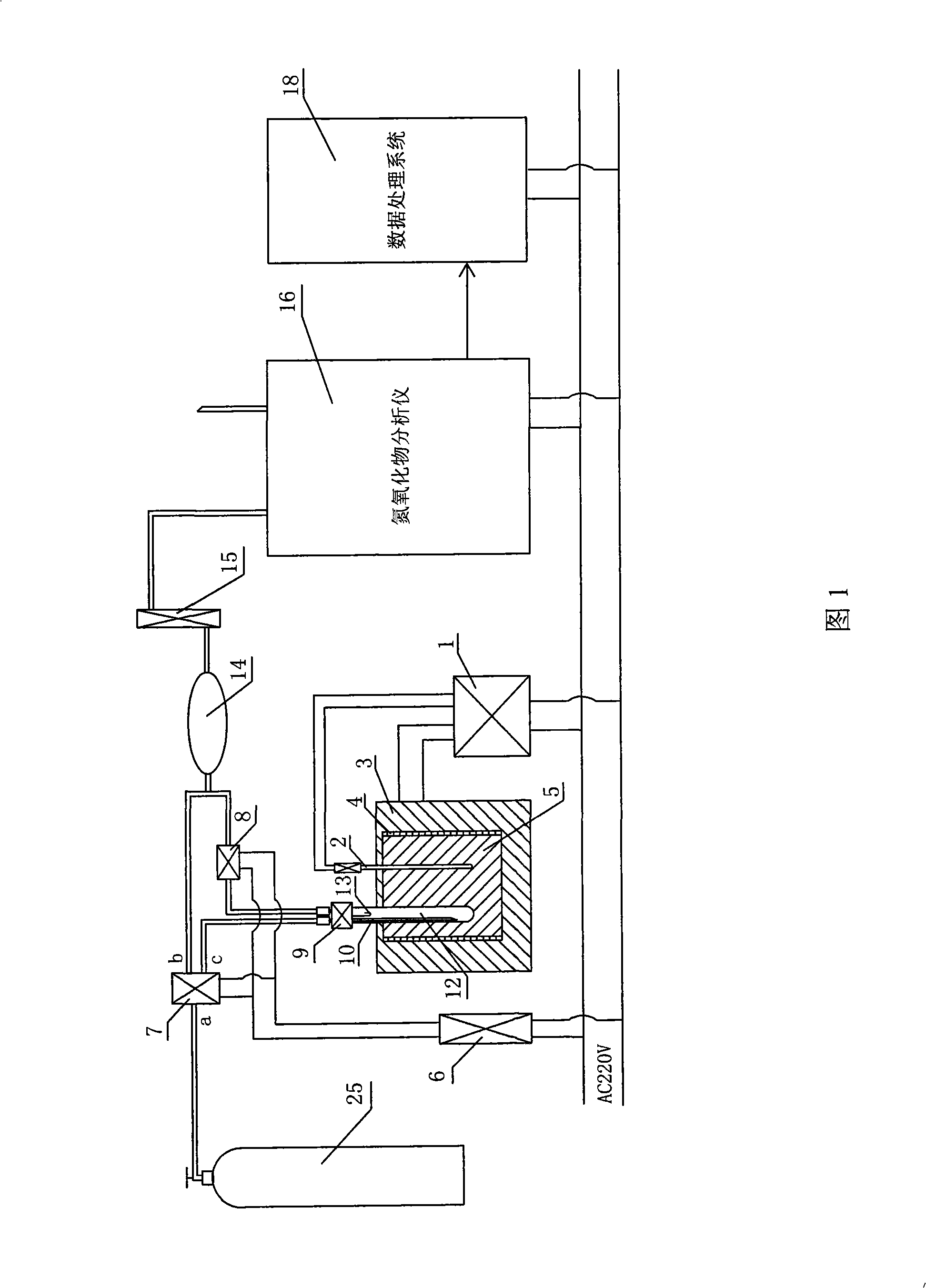

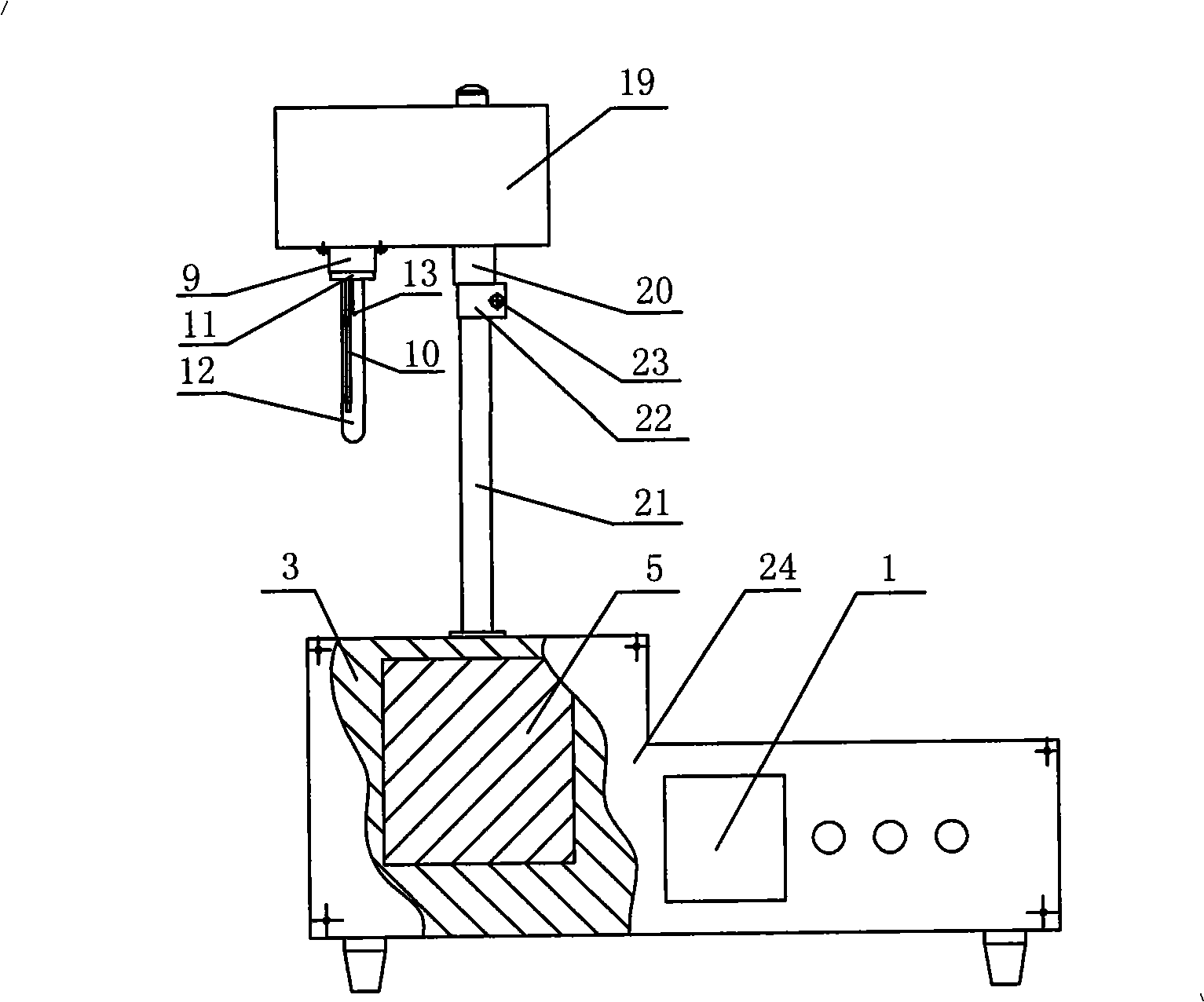

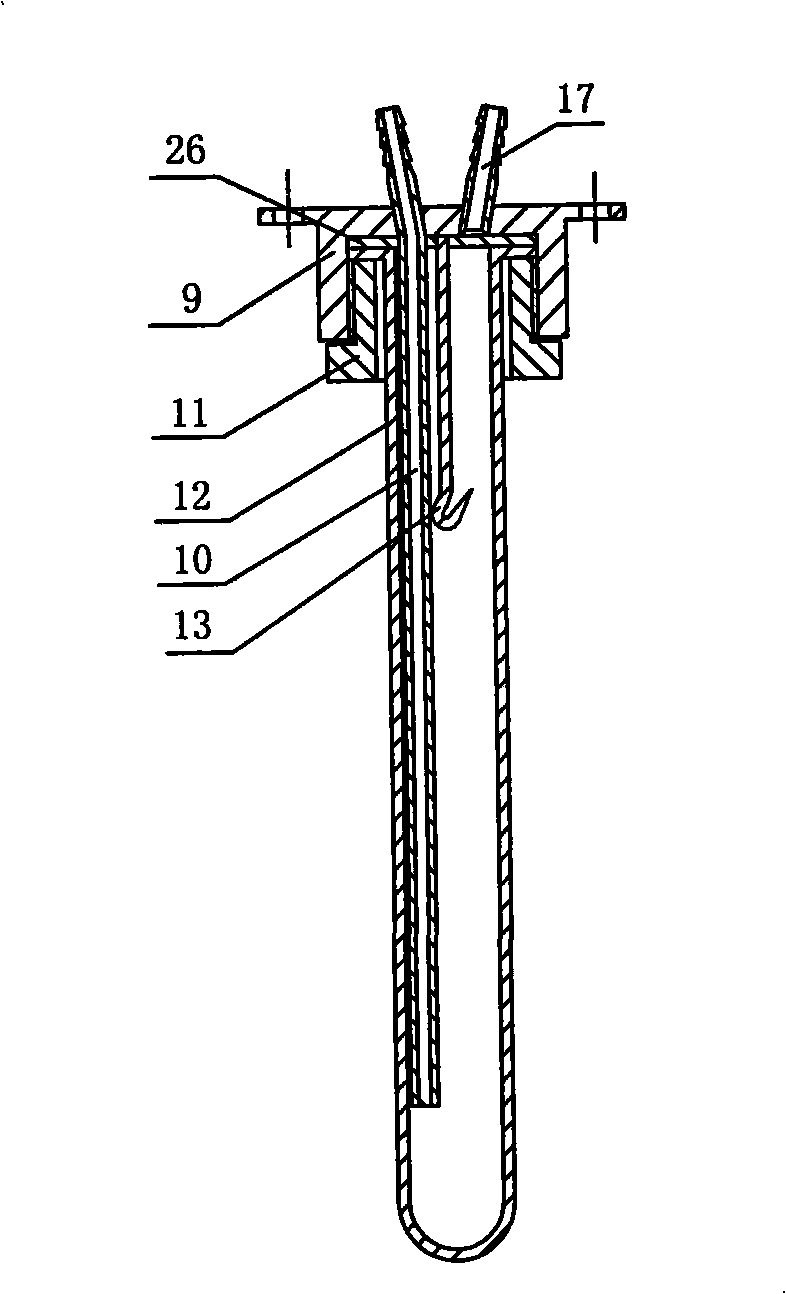

[0018] As shown in FIG. 1, the preferred embodiment of the present invention is based on the existing Abel test and measurement device, which includes a gas collection and transmission device, a nitrogen oxide gas detector 16, and a data collection and processing system 18. The gas collection and transmission device includes a temperature control unit, a gas collection and transmission unit, and a base 24. The temperature control unit includes a temperature control instrument 1, a temperature measuring resistor 2, an insulation layer 3, a heating jacket 4, and a heating furnace body 5. The heating furnace body 5 is a cylinder processed by a metal aluminum column, and three heating holes are evenly distributed on the same circumference of the end surface. The heating jacket 4 is two sets of heating wires of 1600W and 900W, which are tightly clamped on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com