Electric warm water bag and manufacturing method therefor

A water bag, electric heating technology, applied in electric heating devices, electrical components, ohmic resistance heating, etc., can solve the problems affecting the production efficiency and yield of electric heating water bags, limit the variety of styles, and complex structures, and achieve easy cutting. , increase the beauty, choose a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

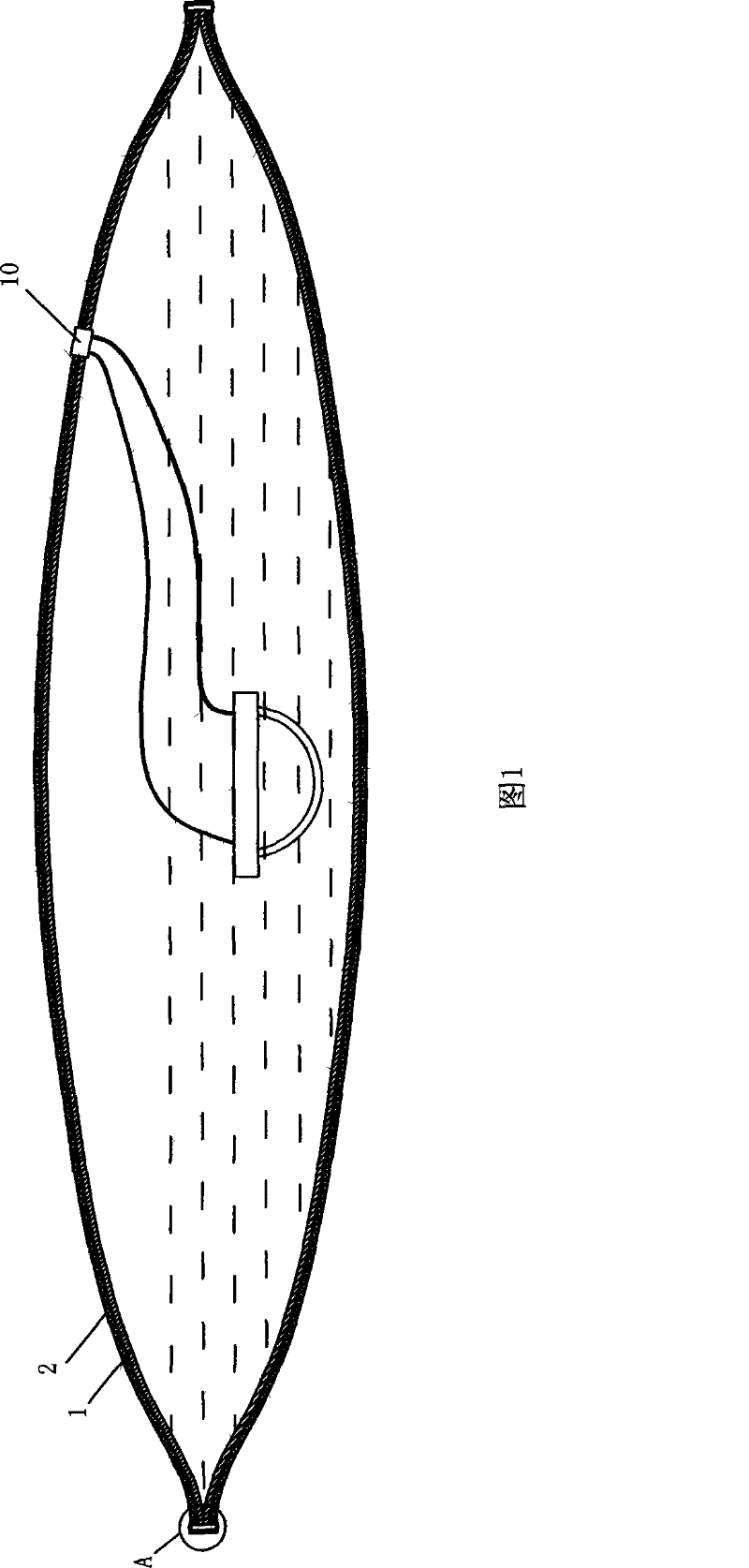

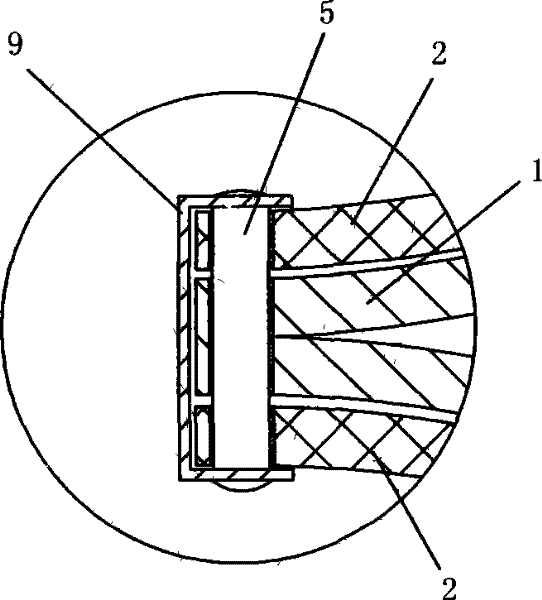

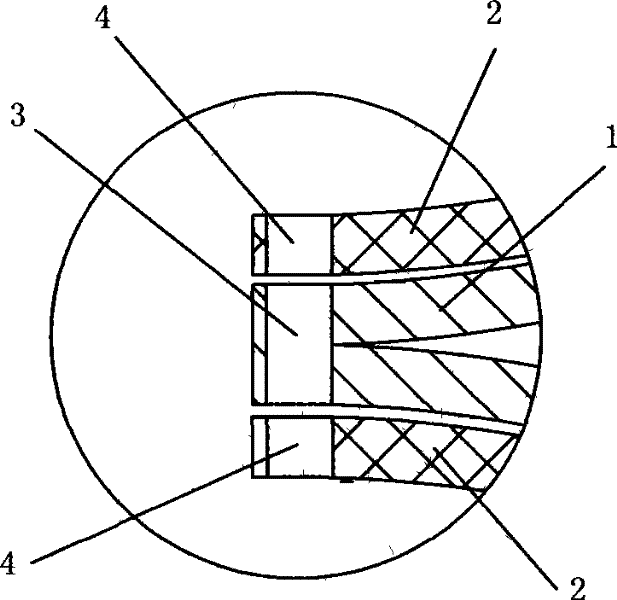

[0031] Such as Figure 1 to Figure 4 As shown, an electric heating water bag includes an independent PVC soft inner sleeve 1 and an outer coat 2, the PVC soft inner sleeve 1 stores liquid, and a first connecting part 3 is provided on its edge, see image 3 and Figure 4 As shown, the outer jacket 2 may be composed of an upper layer and a lower layer arranged in a split shape, or may be formed of an upper layer and a lower layer in an integral shape (not shown), and the upper and lower layers of the outer jacket arranged in a split shape correspond to the described The position of the first connecting part 3 is provided with a second connecting part 4 that is compatible with the jacket, and the first connecting part 3 and the second connecting part 4 are directly connected by the fixing part 5 between the edge of the PVC soft inner jacket 1 and the jacket 2 Fixed connection, in a non-detachable structure. The first connecting part 3 and the second connecting part 4 are severa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com