Zirconium based amorphous alloy and manufacture method thereof

A technology of zirconium-based amorphous alloy and amorphous alloy, applied in the field of amorphous alloy and its preparation, can solve the problem of high requirements for high temperature resistance performance of casting equipment, low requirements for high temperature resistance performance of casting equipment, and high liquefaction temperature of zirconium-based amorphous alloy. problems, to achieve the requirements of improving casting conditions and equipment, low casting conditions, and the effect of reducing liquefaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

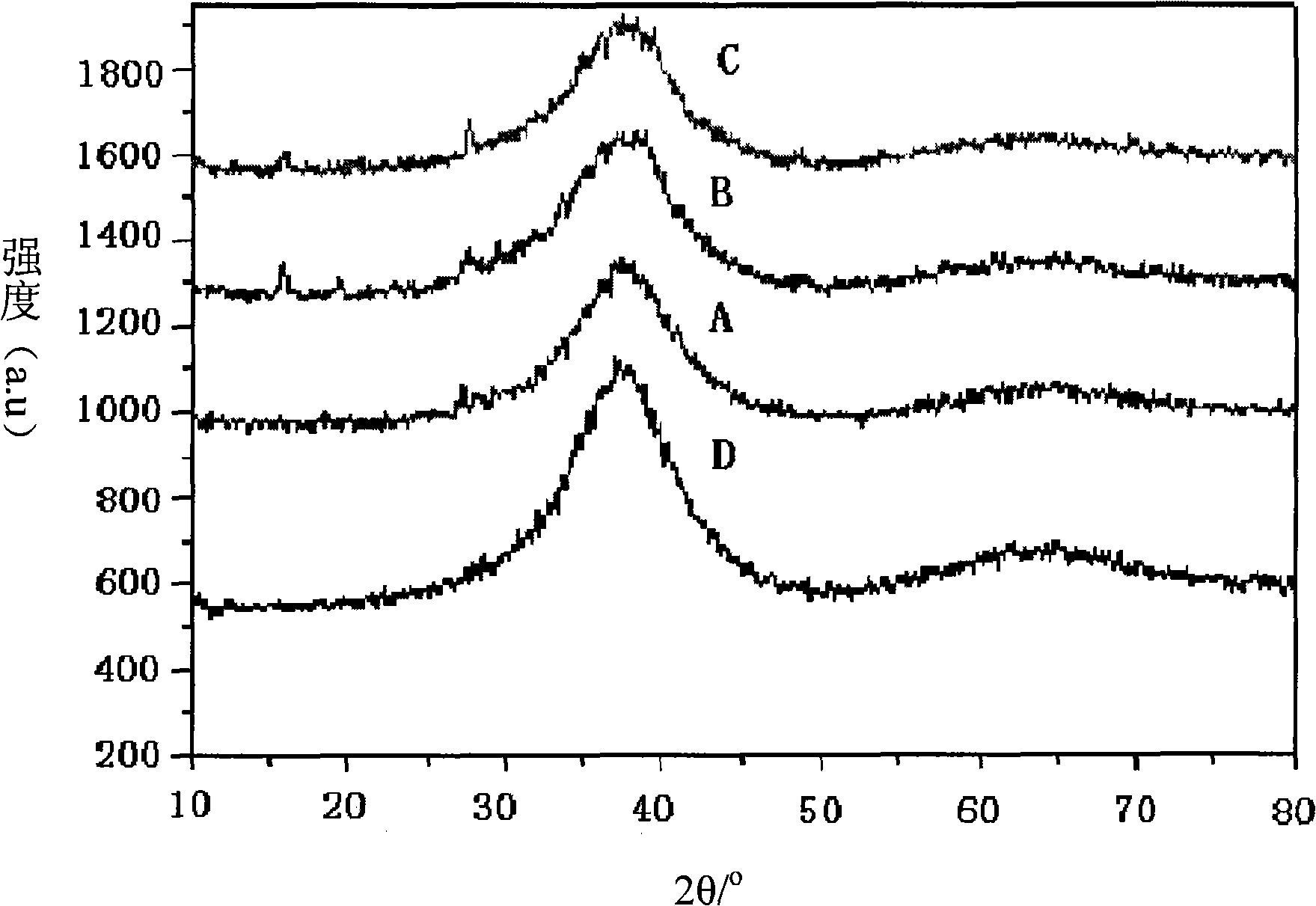

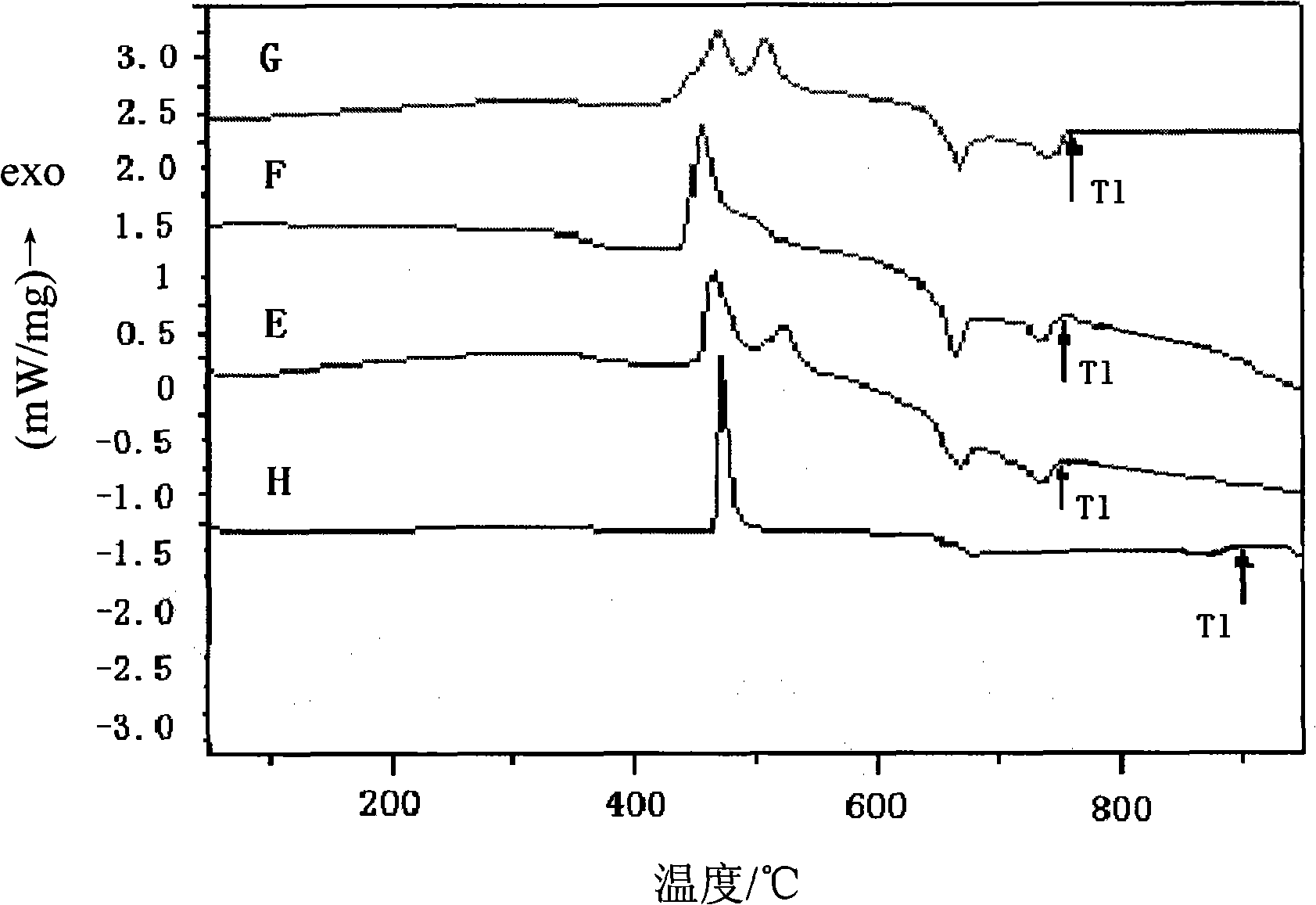

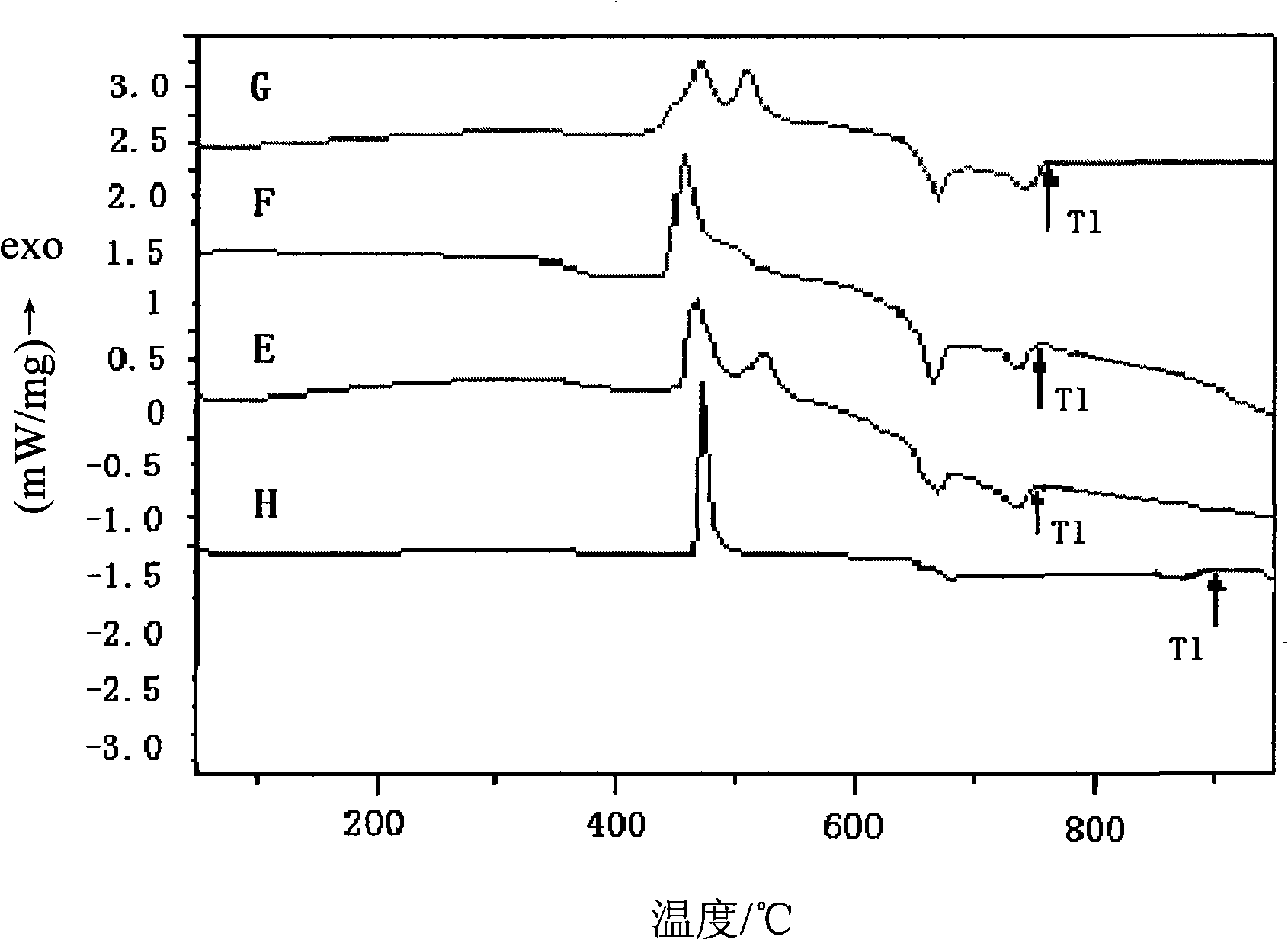

[0022] The molten alloy sample was then subjected to 10 2 The cooling rate of K / s is cooled by water-cooled copper mold, and cast into an amorphous alloy sample D1 with a size of 3 mm × 10 mm × 100 mm. The composition of the amorphous alloy sample D1 is Zr 40 La 15 Ti 8 Cu 7 Ni 7 be 23 .

[0023] Example 2

[0024] This example is used to illustrate the zirconium-based amorphous alloy provided by the present invention and its preparation method.

Embodiment 2

[0026] The molten alloy sample was then subjected to 10 5The cooling rate of K / s is cooled by water-cooled copper mold, and cast into an amorphous alloy sample D2 with a size of 3 mm × 10 mm × 100 mm. The composition of the amorphous alloy sample D2 is Zr 35 La 20 Ti 7 Cu 15 Ni 8 be 15 .

[0027] Example 3

[0028] This example is used to illustrate the zirconium-based amorphous alloy provided by the present invention and its preparation method.

Embodiment 3

[0030] The molten alloy sample was then subjected to 10 3 The cooling rate of K / s is used to cool the copper mold, and cast into an amorphous alloy sample D3 with a size of 3 mm × 10 mm × 100 mm. The composition of the amorphous alloy sample D3 is Zr 35 La 10 Ce 5 Ti 7 Cu 15 Ni 8 be 20 .

[0031] Comparative example 1

[0032] Put 23 grams of amorphous alloy raw material into an electric arc melting furnace (Shenyang Scientific Instrument Factory), evacuate the electric arc melting furnace (at a pressure of 100%), use argon with a purity of 99.0% by volume as the protective gas, and melt at 2000°C For 1 minute, the amorphous alloy raw material is fully melted, and the composition of the amorphous alloy raw material is 50 mol % Zr, 7 mol % Ti, 15 mol % Cu, 8 mol % Ni and 20 mol % Be.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com