A kind of catalytic liquefaction composite adhesive of bamboo chips and preparation method thereof

A composite adhesive and catalytic liquefaction technology, which is applied in the direction of adhesive types, adhesive additives, wood fiber material adhesives, etc., can solve the problems affecting the promotion and application of adhesives, affecting the availability of liquefied products, increasing the production cost of adhesives, etc. problems, achieve good environmental and economic benefits, reduce production costs, and reduce formaldehyde release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

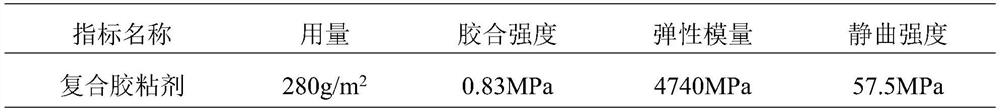

Examples

Embodiment 1

[0027] A kind of bamboo chip catalytic liquefaction composite adhesive is prepared by the following components in parts by weight: 100 parts of bamboo chip powder, 50 parts of chrome-containing leather chips, 25 parts of solubilizer (polypropylene glycol 4000), 5 parts of formaldehyde, 20 parts of Diluent (gelatinized starch with 20% starch content). Among them, the water content of the bamboo powder is 6-8% and the particle size is 0.2-0.5 mm, which is obtained by soaking the processing residues from bamboo trunks, bamboo branches, bamboo nodes or bamboo leaves with 1-2% hydrochloric acid solution for 2 hours. obtained by filtering. The chrome leather shavings are cowhide chrome tanned and smoothed leather shavings with a water content of 50-55% and a content of 3.0-3.5% of chromium trioxide.

[0028] The preparation method of above-mentioned composite adhesive is specifically as follows:

[0029] Add bamboo powder, chrome-containing leather chips, and solubilizer to the dr...

Embodiment 2

[0031] A kind of bamboo chip catalytic liquefaction composite adhesive is prepared by comprising the following components in parts by weight: 130 parts of bamboo chip powder, 70 parts of chrome-containing leather chips, 30 parts of solubilizer (polypropylene glycol 6000), 5 parts of formaldehyde, 20 parts Part diluent (gelatinized starch with a starch content of 30%). Among them, the water content of the bamboo powder is 6%-8% and the particle size is 0.2-0.5mm, which is obtained by impregnating the processing residues from bamboo trunks, bamboo branches, bamboo nodes or bamboo leaves with 1%-2% hydrochloric acid solution Obtained by filtration after 2h. The chrome leather shavings are cowhide chrome tanned and smoothed leather shavings with a water content of 50-55% and a content of 3.0-3.5% of chromium trioxide.

[0032] The preparation method of above-mentioned composite adhesive is specifically as follows:

[0033] Add bamboo powder, chrome-containing leather chips, and ...

Embodiment 3

[0035]A kind of bamboo chip catalytic liquefaction composite adhesive is prepared by comprising the following components in parts by weight: 150 parts of bamboo chip powder, 70 parts of chrome-containing leather chips, 50 parts of solubilizer (polypropylene glycol 10000), 10 parts of formaldehyde, 30 parts Part diluent (starch content is the gelatinized starch of 30%) wherein, the water content of bamboo powder is 6~8% and particle diameter is 0.2~0.5mm, and it is obtained by coming from bamboo stem, bamboo branch, bamboo joint or bamboo leaf It is obtained by immersing the processing residue with 1-2% hydrochloric acid solution for 2 hours and then filtering. The chrome leather shavings are cowhide chrome tanned and smoothed leather shavings with a water content of 50-55% and a content of 3.0-3.5% of chromium trioxide.

[0036] The preparation method of above-mentioned composite adhesive is specifically as follows:

[0037] Add bamboo powder, chrome-containing leather chips,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com