High-performance real silk material production equipment

A production equipment and high-performance technology, applied in the direction of textiles, papermaking, yarn, etc., can solve the problems of easy deformation and wrinkle of ordinary silk products, achieve good elasticity, excellent wrinkle resistance, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

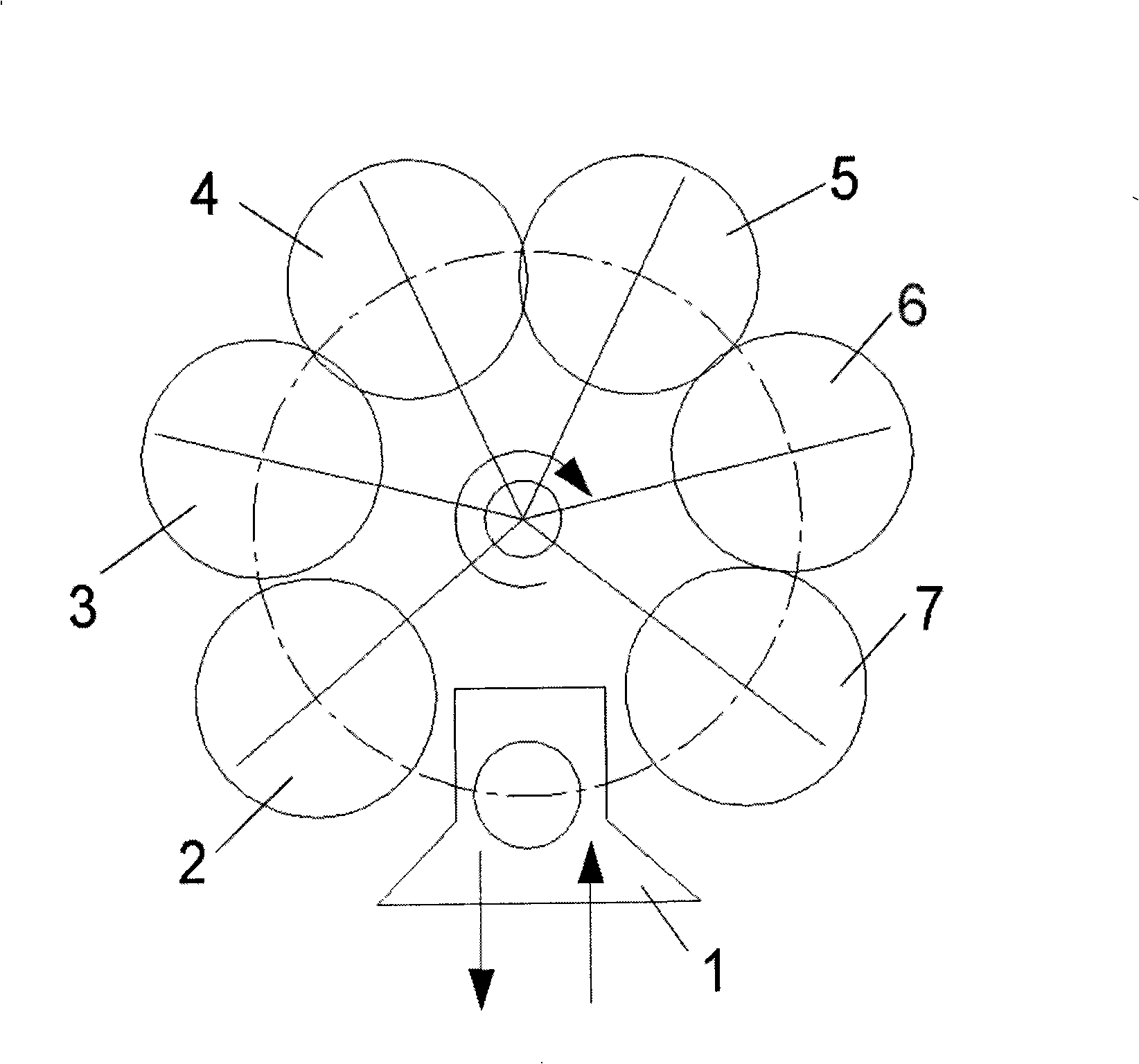

[0021] Example: such as figure 1 As shown, a production equipment for high-performance silk materials, it includes a feed and discharge port 1, a reaction kettle 2, a cleaning tank 3, a rinsing tank 4, a scouring kettle 5, and a scouring kettle arranged in sequence and surrounded by a circle. 26. Scouring kettle 3 7; also includes the ability to lift and rotate the basket containing the material to the feed and discharge port 1, reaction kettle 2, cleaning tank 3, rinsing tank 4, scouring kettle 1 5, scouring kettle Two 6, the rotary arm on the top of the refining kettle three 7.

[0022] The production equipment also includes an automatic temperature control unit, an automatic liquid level control unit, an automatic action control unit, an automatic liquid path control unit, an interface parameter display unit, a process position display unit, and an automatic / manual function switching unit.

[0023] The technological action process of this production equipment is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com