Coolant injection device and control method of rotary compressor

A technology of rotary compressor and compressor pump, applied in the direction of rotary piston type/swing piston type pump components, components of pumping devices for elastic fluids, mechanical equipment, etc. Reduce the efficiency of the machine system and other problems, and achieve the effect of preventing the reduction of efficiency, simple structure and easy change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

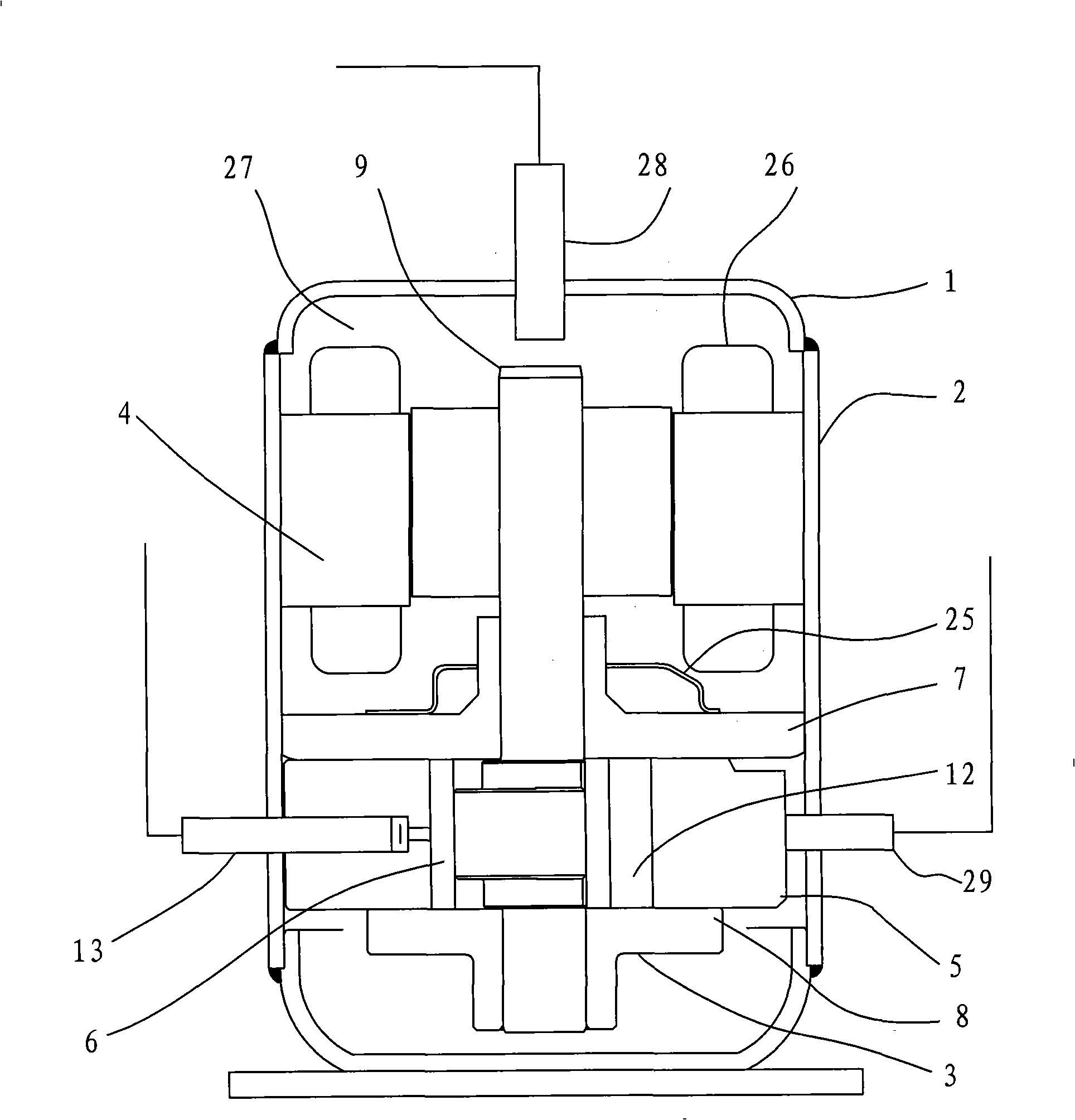

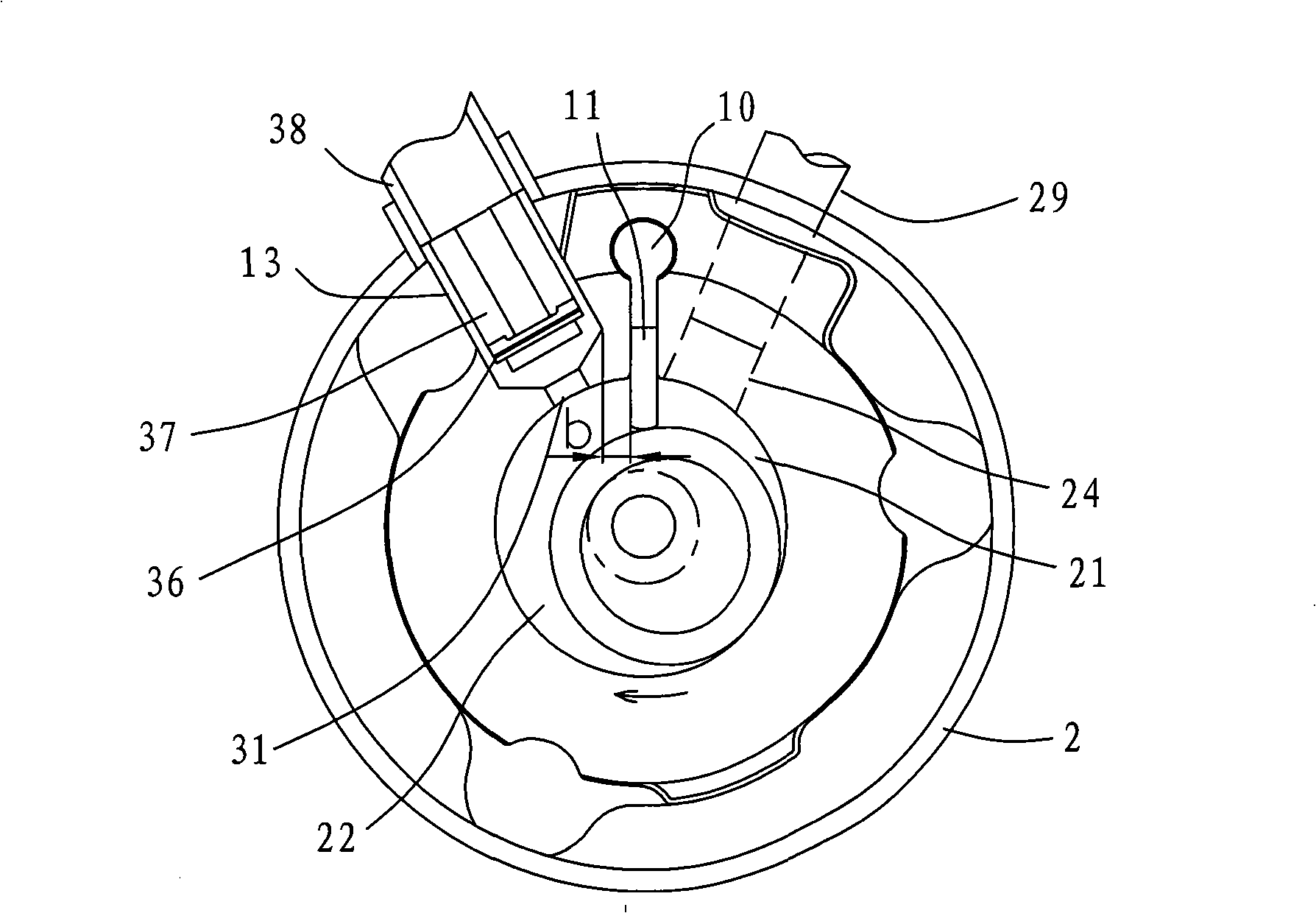

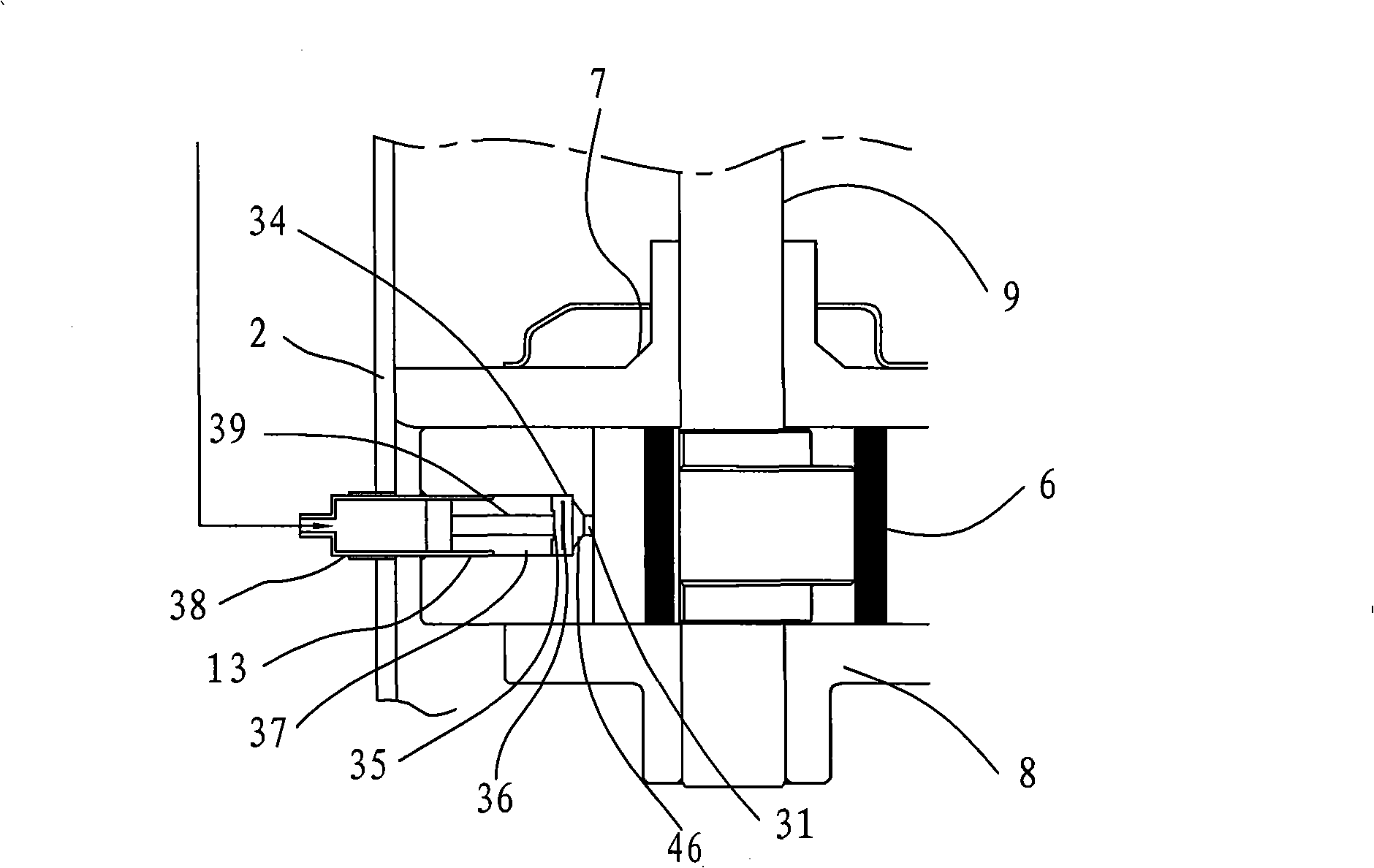

[0032] see figure 1 , figure 2 , a refrigerant charging device for a rotary compressor, including a motor 4 set in a sealed casing 2 and a compressor pump body 3 connected to the motor, the compressor pump body includes a cylinder 5, and the cylinders are respectively arranged on the upper and lower parts of the cylinder. The main bearing 7 and the auxiliary bearing 8, the crankshaft 9 connected with the motor, the cylinder compression chamber 12 that accommodates the freely rotatable piston 6 connected to the crankshaft, the slide plate 11 whose front end is crimped on the outer circle of the piston, and the storage slide Slider groove 10 for the sheet. The cylinder 5, the main bearing 7 or the auxiliary bearing 8 of the compressor pump body 3 are provided with a refrigerant charging device, which at least has a charging hole 31 perforated in the cylinder compression chamber 12 and a charging hole 31 which is opened as the pressure of the cylinder compression chamber change...

no. 2 example

[0044] see Figure 10 , The end of the valve seat body 37 is press-fitted with a valve cover 55 . In addition, the valve cover 55 has the function of the lift stopper 34 . The joint portion between the filling pipe 38 and the valve seat body 37 is joined by welding. This design simplifies the machining of the cylinder cross hole 32, and also has the advantage that the valve stroke s can be adjusted correctly in advance. And it is also possible to more accurately install the refrigerant charging device 13 on the cylinder horizontal hole 32 . Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com