Water-cooled heat exchanger and its manufacturing method

A technology of heat exchanger and manufacturing method, which is applied to evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of low outlet water temperature, large volume, and high cost of use, and achieves improved heat exchange effect and heat exchange area. Large, low-cost manufacturing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

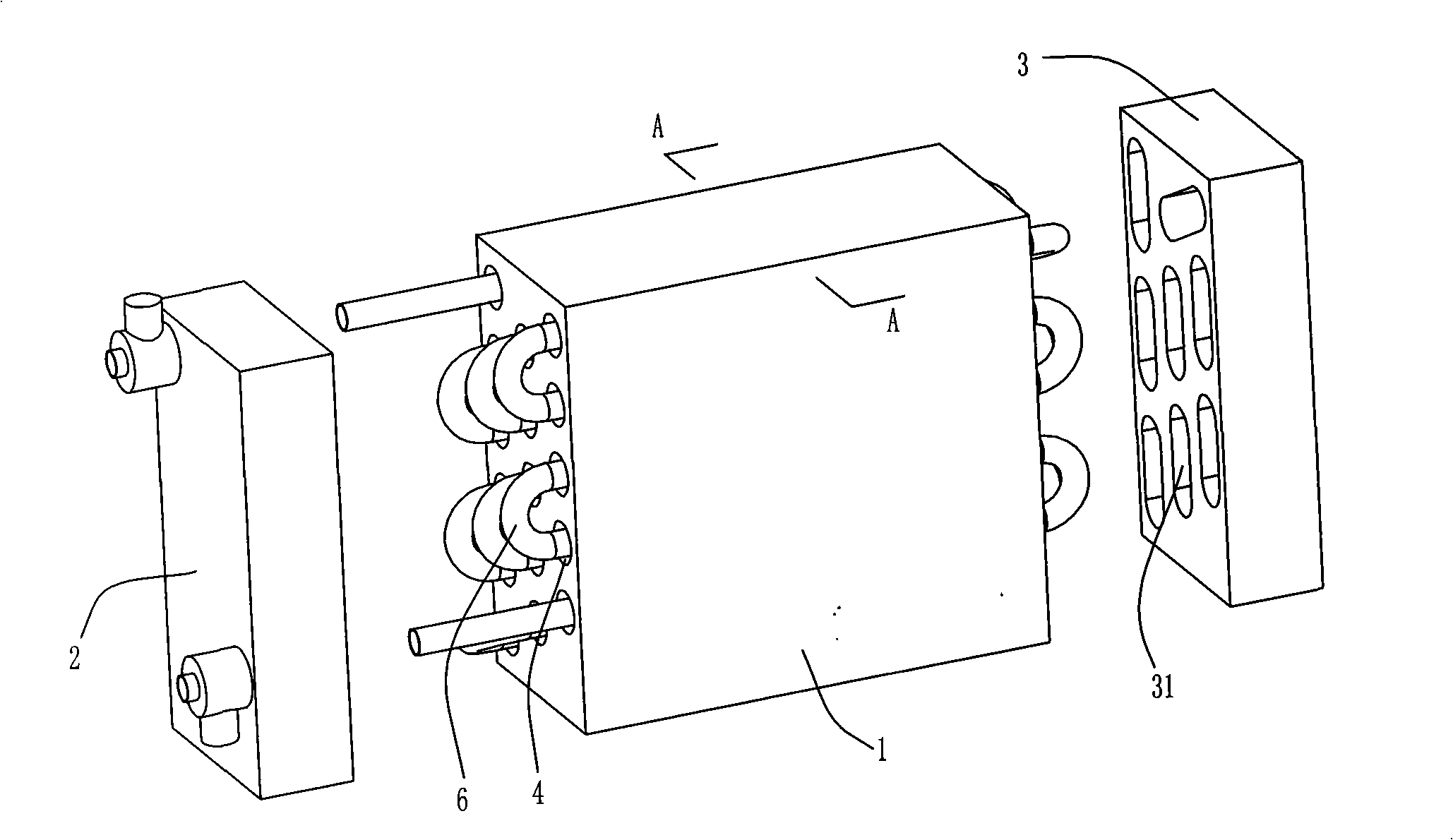

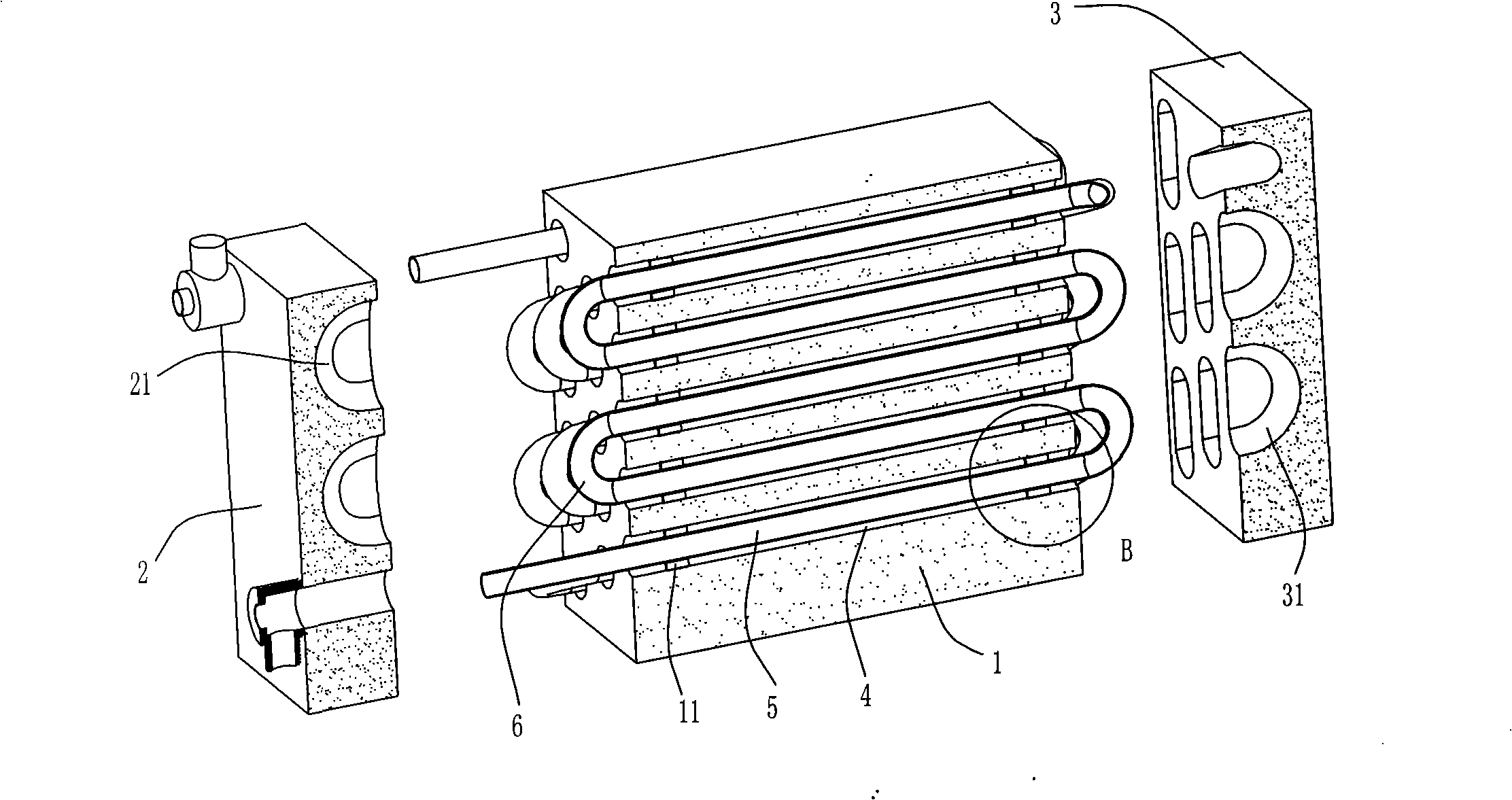

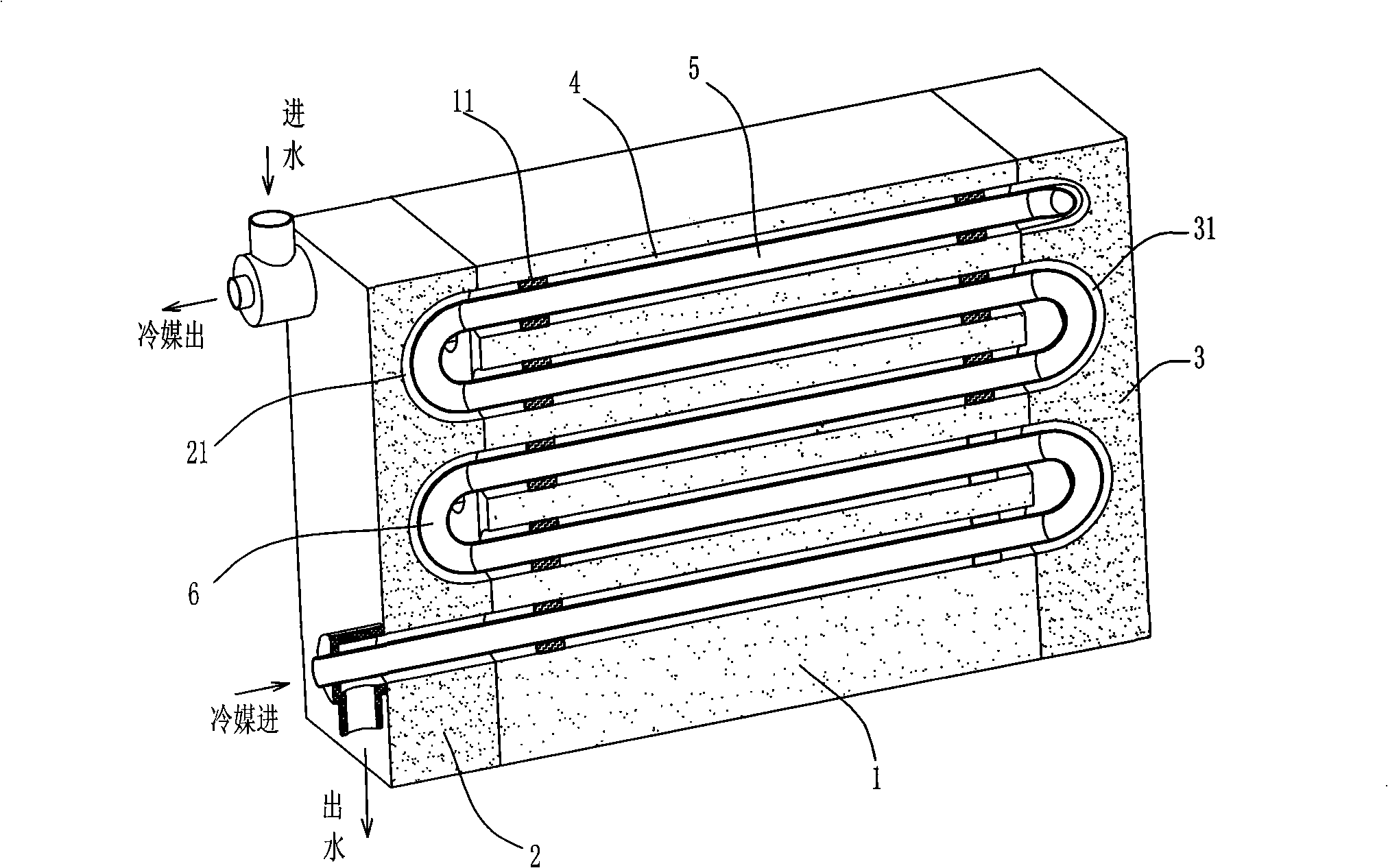

[0020] refer to Figure 1 to Figure 5 , a water-cooled heat exchanger, which includes a main body 1 and front and rear end covers 2, 3, a water flow channel 4 and a refrigerant pipeline 5 are respectively arranged inside the main body 1, and the water flow channel 4 and the refrigerant pipeline 5 inside the main body 1 have respectively Multiple refrigerant pipes are arranged side by side after running through the main body 1. Each refrigerant pipe 5 is placed inside the water flow channel 4. The water flow channels 4 are connected at the front and rear end covers. Each refrigerant pipe 5 is connected at the front and rear ends of the main body 1. The head 6 communicates with at least one other refrigerant pipeline 5 respectively, and each water flow channel 4 communicates with at least one other water flow channel through the water chambers 21 and 31 provided in the front and rear end covers 2 and 3 respectively, and the main body 1 and the front and rear end covers 2 , 3 Sea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap