Automatic test equipment and method for touch device

A technology of automatic test equipment and touch devices, applied in circuit breaker testing, instruments, measuring electricity and other directions, can solve the problem of lack of special equipment, and achieve the effect of improving efficiency, saving costs and reducing defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

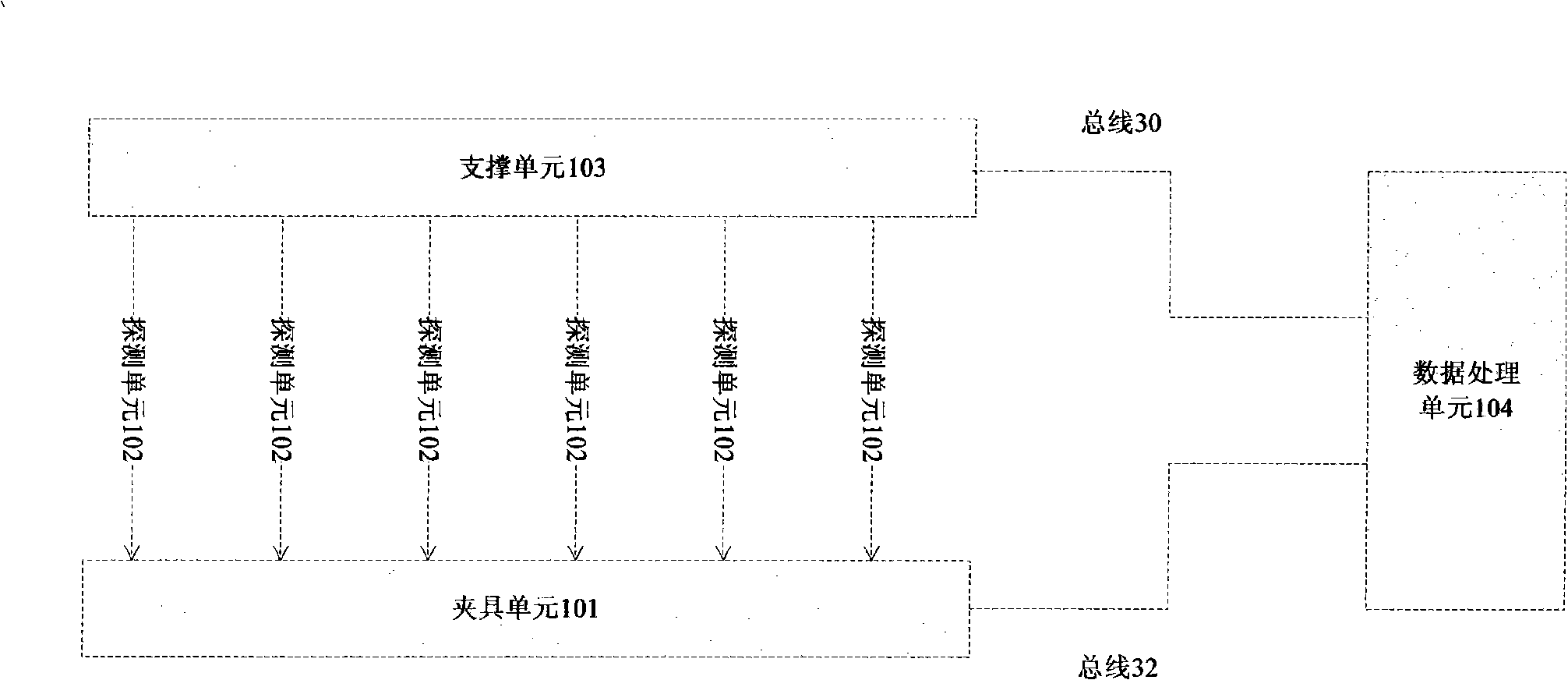

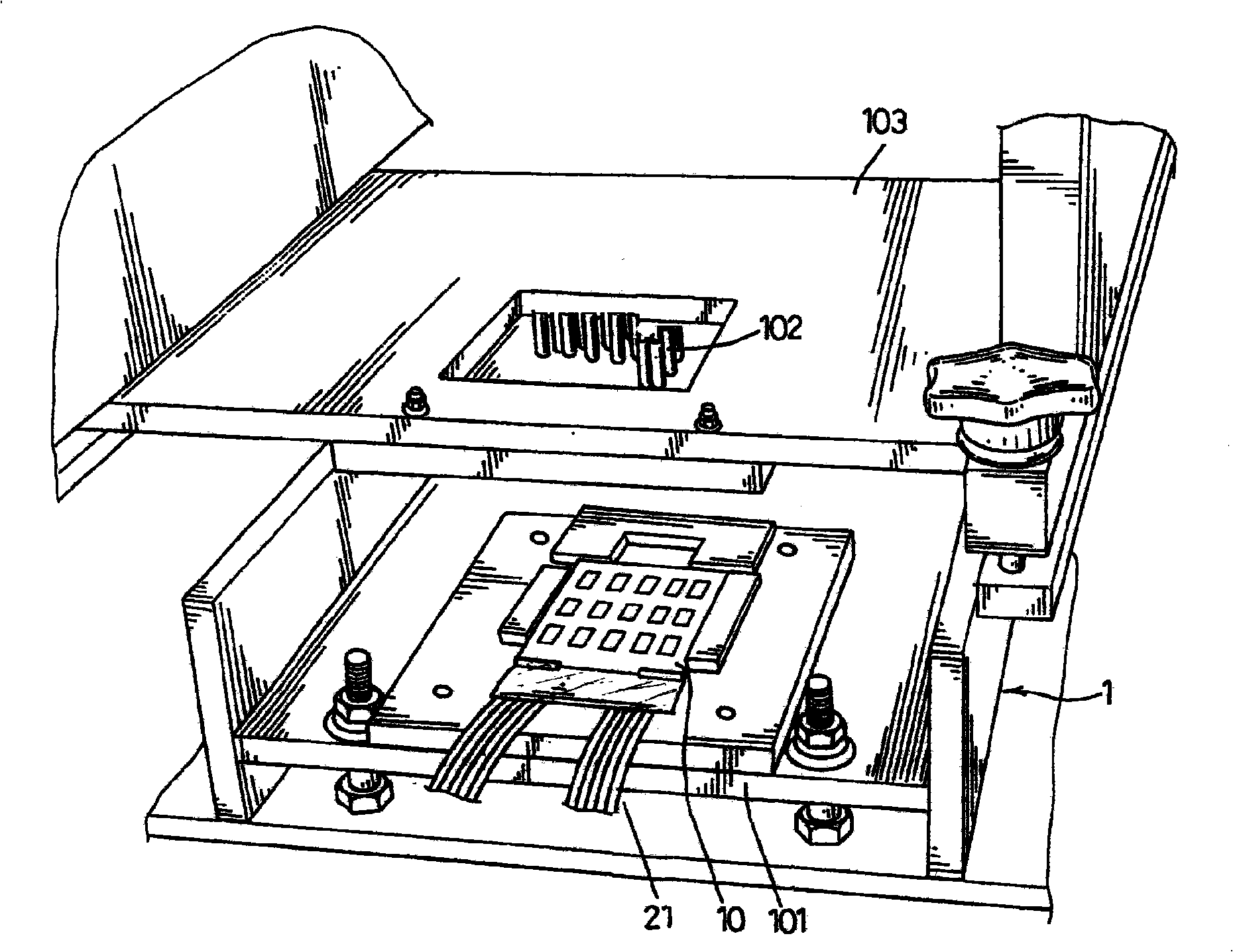

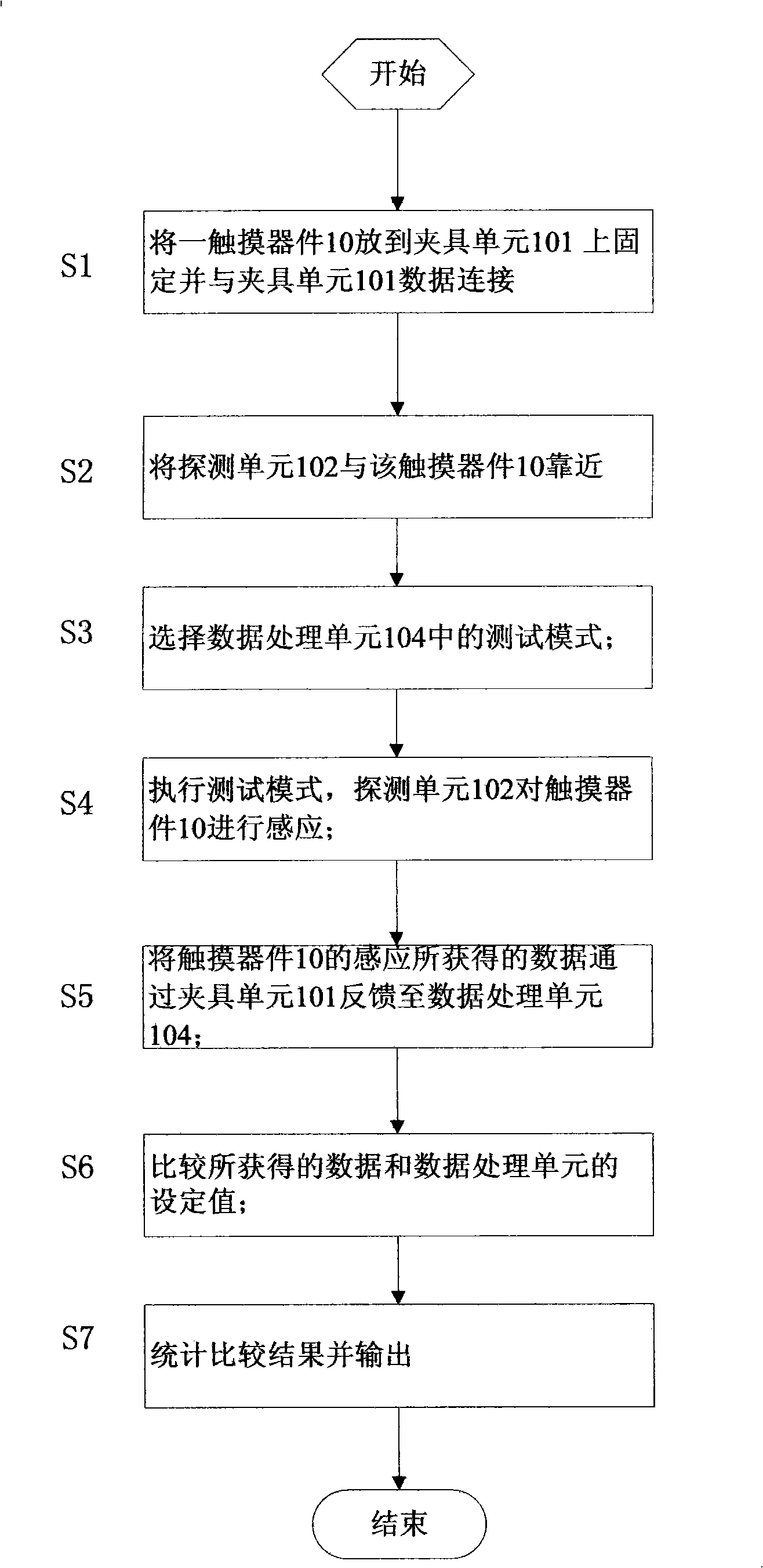

[0028] Such as figure 1 with figure 2 , a kind of equipment 1 for automatically testing the touch device 10 includes: a fixture unit 101, which is a common fixture table with a fixed function; User operation, the support unit 103 is a device that provides control of the detection unit and fixes the position of the detection unit, and the data processing unit 104 is a device such as a single-chip microcomputer or computer processing control.

[0029] The clamp unit 101 is used to fix the touch device 10, which is a capacitive touch panel in this embodiment, and may also be other devices such as touch keys. The fixture unit 101 and the data processing unit 104 are connected through an inter-integrated circuit bus 32 (I2C, Inter-Integrated Circuit) interface, and the data connection between the fixture unit 101 and the touch device 10 is through the adapter 21 converted between the I2C interface .

[0030] The detection unit 102 is a plate electrode fixed on the support unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com