Growth plate curing and dying process of lead-acid accumulator

A lead-acid battery, solidification and drying technology, applied in the direction of the lead-acid battery electrode, etc., can solve the problems of positive electrode active material sliming and falling off, affecting battery life, and rusting of the plate frame, so as to achieve not easy falling off, prolong service life, reduce wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

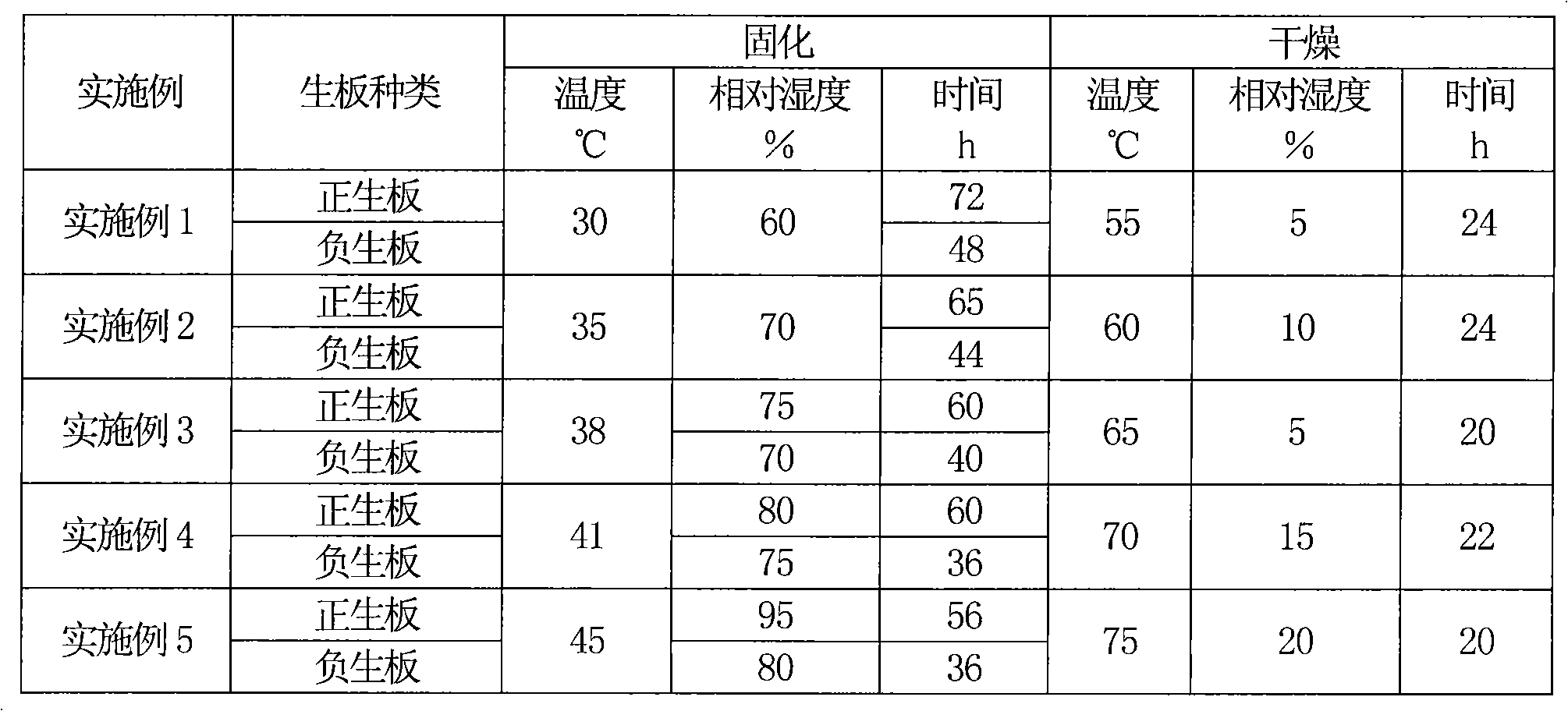

[0010] The present invention determines the preferred environmental humidity, temperature and time through repeated tests. The method can make the moisture in the green board slowly dissipate, which is beneficial to the oxidation of free lead and the generation of voids in the green board; the curing and drying temperature is strictly controlled, and the use of long The time curing method controls the occurrence and reaction speed of the internal reaction of the green board, so that the internal components of the green board, especially 3PbO·PbSO 4 ·H 2 O and 4PbO·PbSO 4 Keep the right proportions. Empirical data proves that the proper proportion of 3PbO·PbSO4·H2O and 4PbO·PbSO4 in the green board should be about 20% of the latter to ensure that the battery has both good initial performance and cycle life. At the same time, the use of long-term curing and drying methods, on the one hand, makes the green board strength and free lead content controlled within the range of process re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com