U-shaped straight line servo motor

A servo motor, linear technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems affecting the control performance of the linear motor, reduce the running stability of the motor, weaken the harmonic component of the magnetic field, etc. Rigidity, good effect of the rigidity of the mover structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

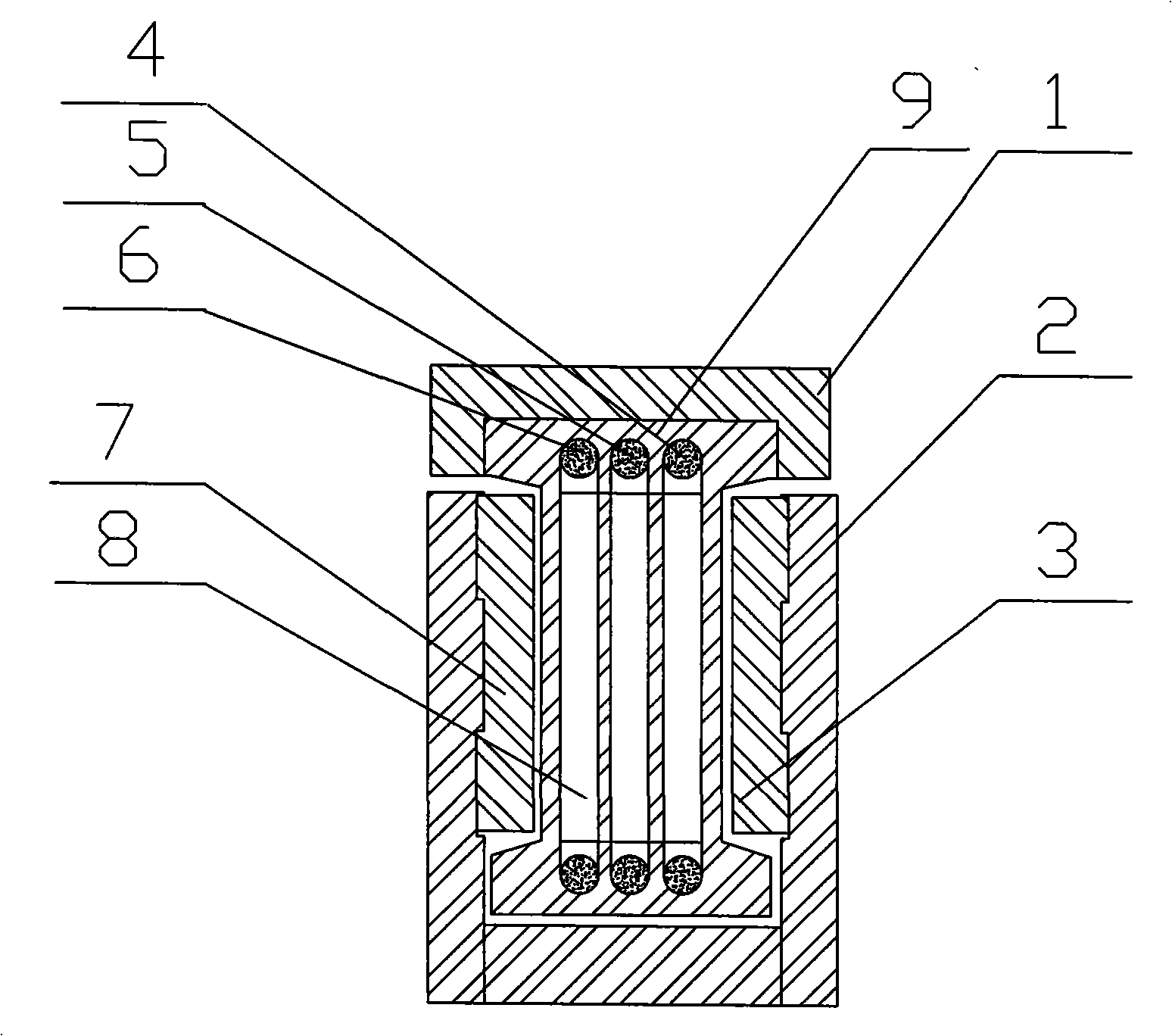

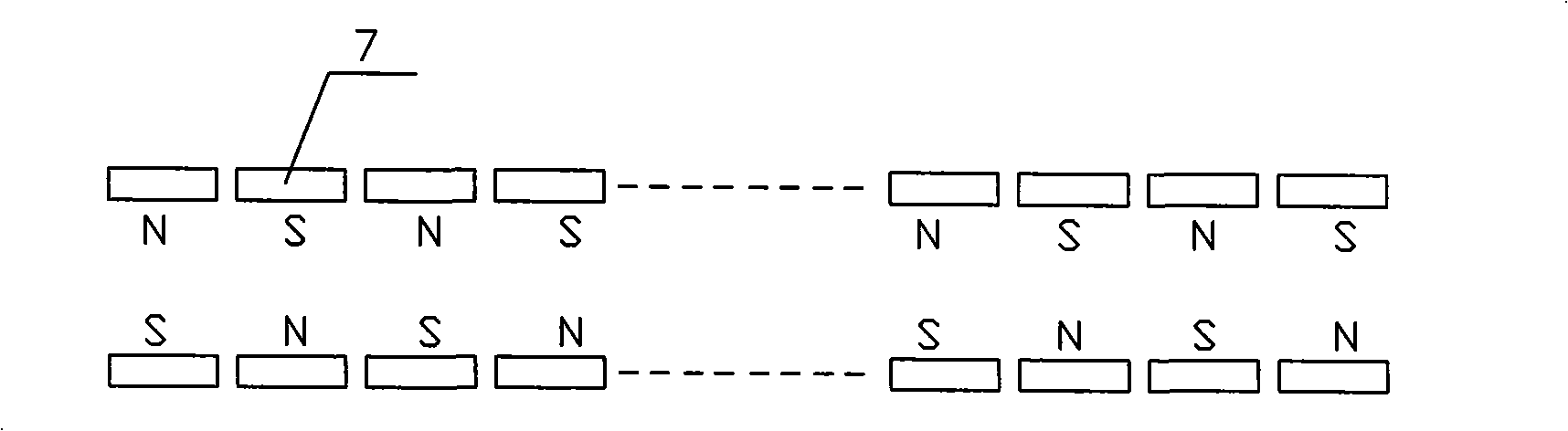

[0014] See attached figure 1 , 2 , 3, 4, the present invention includes a stator, a mover 9, a mounting table 1, coil windings 4, 5, 6, the stator includes a magnetic steel 7, a U-shaped base 2, and a coil is embedded in the mover 9 The upper ends of the windings 4, 5, and 6 are connected to the installation table 1 fixedly connected with the linear guide rail, and the other ends are clamped between the magnetic steel 7 and form an air gap 3 with the magnetic steel 7, which is characterized in that: the magnetic steel The steel 7 consists of a single magnetic pole with an N pole and an S pole. Multiple sets of magnetic steel 7 are arranged symmetrically and parallelly on both sides of the U-shaped base 2U-shaped cavity along the axis of the mover 9, and two adjacent positions The magnetic poles of the magnetic steel 7 are opposite in polarity.

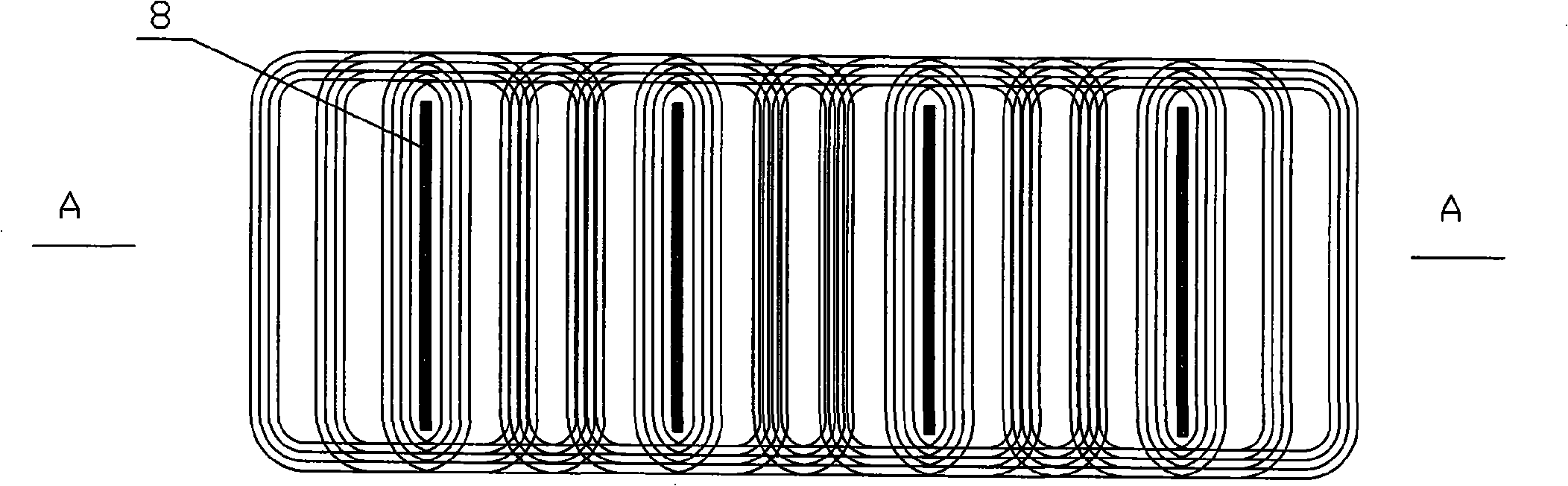

[0015] In the present invention, an aluminum plate 8 is arranged in the middle of the winding of the mover 9 .

[0016] In the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com