Fibrilia hygroscopic layer

The technology of hemp fiber and hygroscopic layer is applied in the field of sanitary hygroscopic articles for external use, which can solve the problems of unstable hygroscopic effect, poor fiber cohesion ability, and difficulty in tableting and molding, and achieve stable hygroscopic effect, strong hygroscopic ability, and improved hygroscopic ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

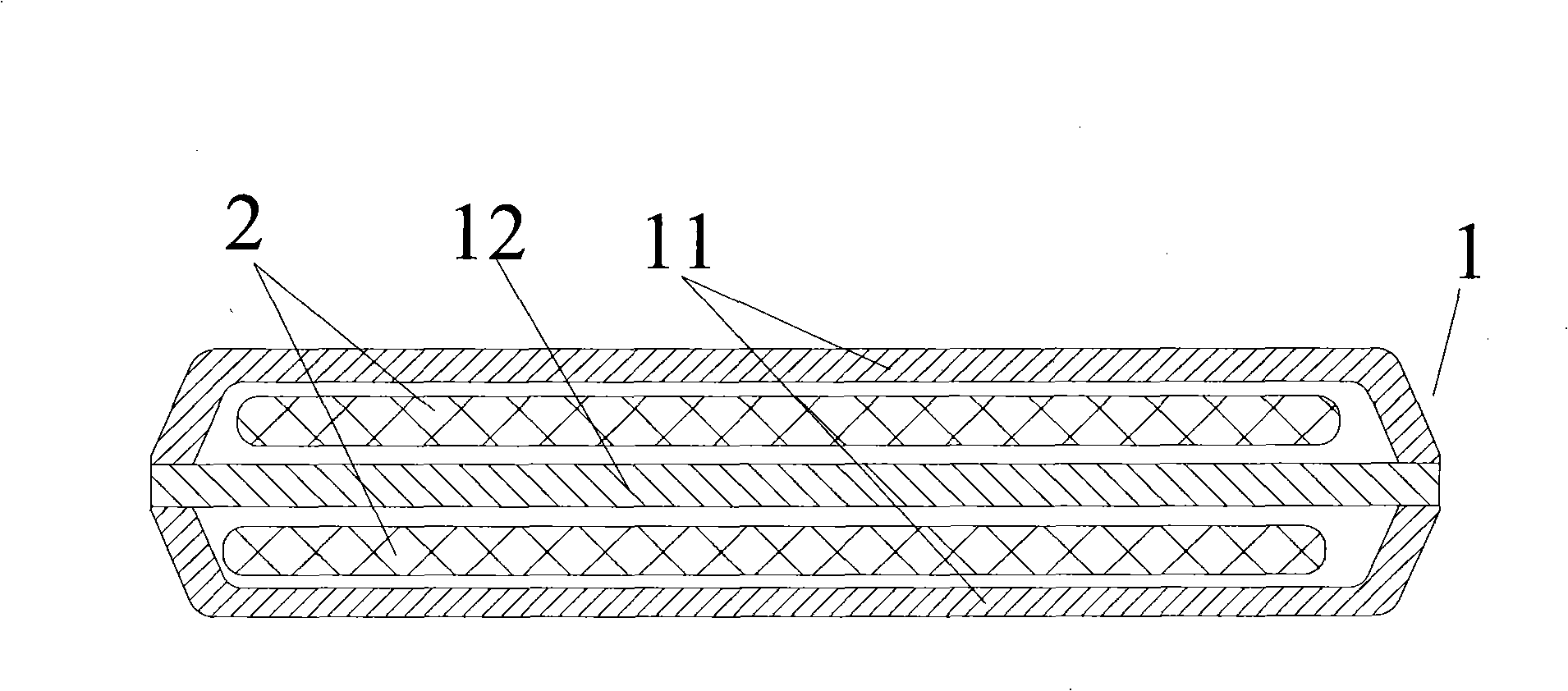

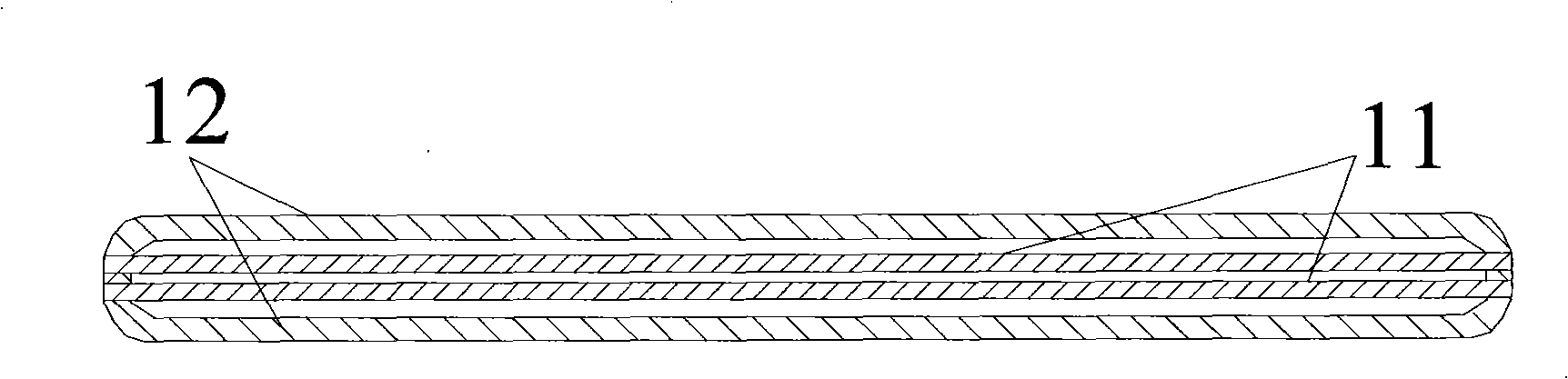

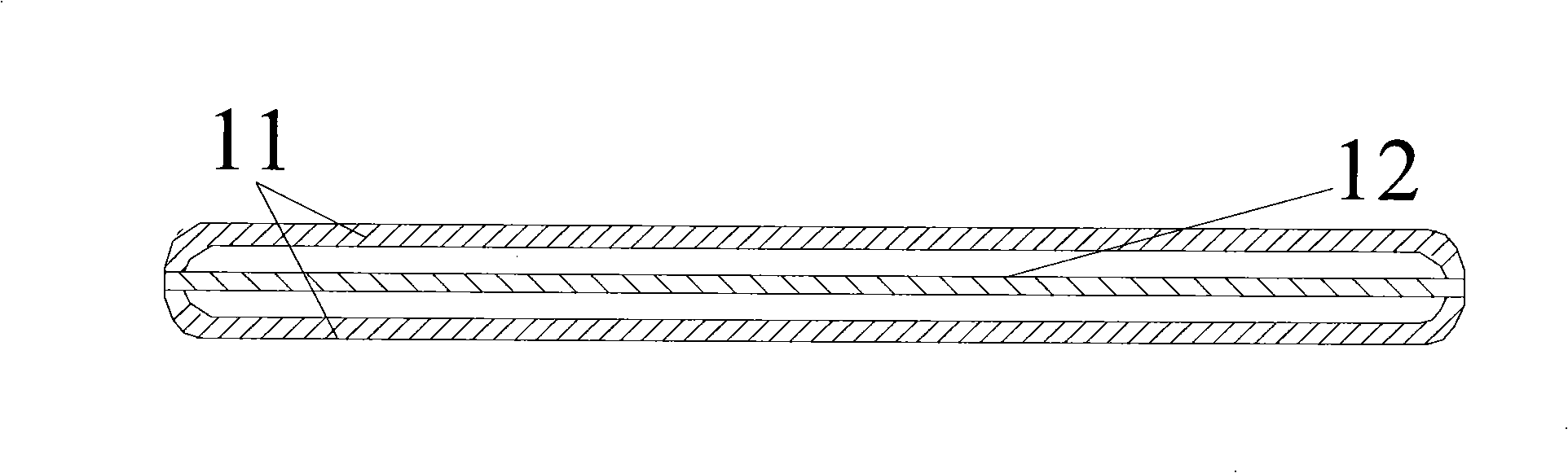

[0020] Such as figure 1 As shown, the longitudinal sectional view of the hygroscopic layer in the present invention, the hygroscopic layer includes a mixed hygroscopic sheet 11 with a thickness of about 1-5 mm, which contains crushed jute fibers and crushed wood pulp paper, and is sandwiched between the upper and lower layers. The wood pulp paper hygroscopic sheet 12 containing only crushed wood pulp paper with a thickness of about 1-5 mm between the mixed hygroscopic sheets 11 is sandwiched between the two intervals formed by the mixed hygroscopic sheet 11 and the wood pulp paper hygroscopic sheet 12 Super absorbent resin (SAP) layer2. In order to prevent loss of the superabsorbent resin due to leakage, the upper and lower layers of the mixed hygroscopic sheet 11 and the edge of the wood pulp paper hygroscopic sheet 12 can be pressed together so that the superabsorbent resin layer 2 is fixed in the gap. The average length of the jute fibers in the hybrid hygroscopic sheet 11...

Embodiment 2

[0026] The average length of the hemp fiber and the content of the hemp fiber in the moisture-absorbing sheet 1 in Example 1 were changed. In this embodiment, the average length of the hemp fiber in the hygroscopic sheet 1 is 1mm, and the hemp fiber content is 30%. Because the average length of the hemp fiber is shorter than 5 mm, the fibers are easier to mix evenly and improve the moisture absorption stability; because the fibers with a shorter average length have poor cohesion ability, the content of the hemp fiber in the wet sheet is correspondingly reduced, but to a certain extent weaken the antibacterial ability and air permeability of the hygroscopic layer, but the hemp fiber content still has good hygroscopic stability, air permeability, and antibacterial and antibacterial ability when the content of hemp fiber is 30wt%.

Embodiment 3

[0028] The average length of the hemp fiber and the content of the hemp fiber in the moisture-absorbing sheet 1 in Example 1 were changed. In this embodiment, the average length of the hemp fiber in the hygroscopic sheet 1 is 0.5 mm, and the content of the hemp fiber is 10 wt%. At this time, because the average length of the hemp fiber is shorter, it is easier to mix evenly, and the moisture absorption stability is higher, but at the same time, it is necessary to increase the content of raw pulp paper in the moisture-absorbing sheet. Compared with hemp fiber content of 30wt% and 50wt%, the capacity is lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com