Jhouta blended spinning method and blended yarn spun by the method

A jute and open-end spinning technology, which is applied to continuous winding spinning machines, spinning machines, open-end spinning machines, etc., can solve the problems of difficult weaving and easy knotting of yarns, and reduce external damage , good yarn quality and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

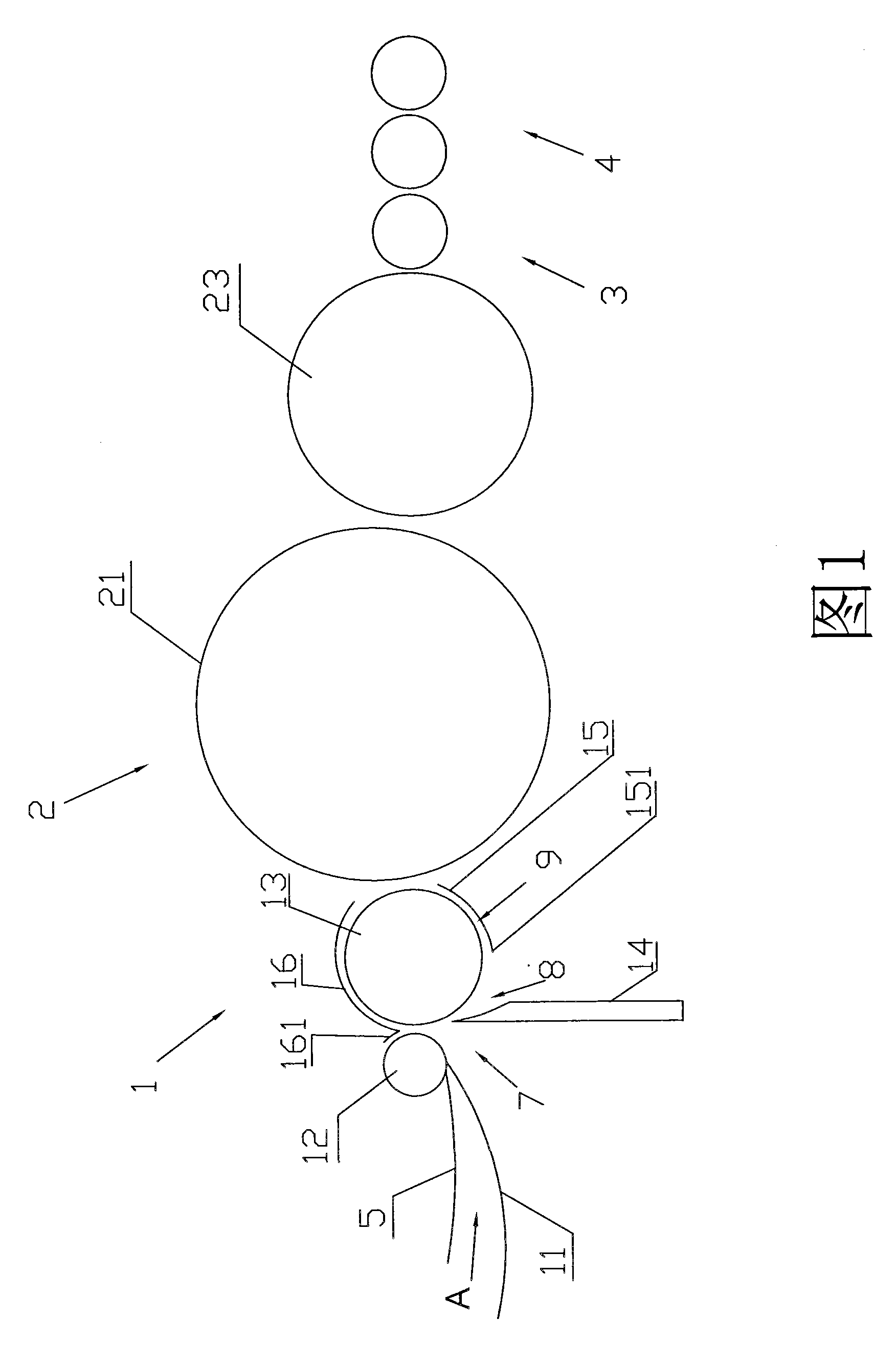

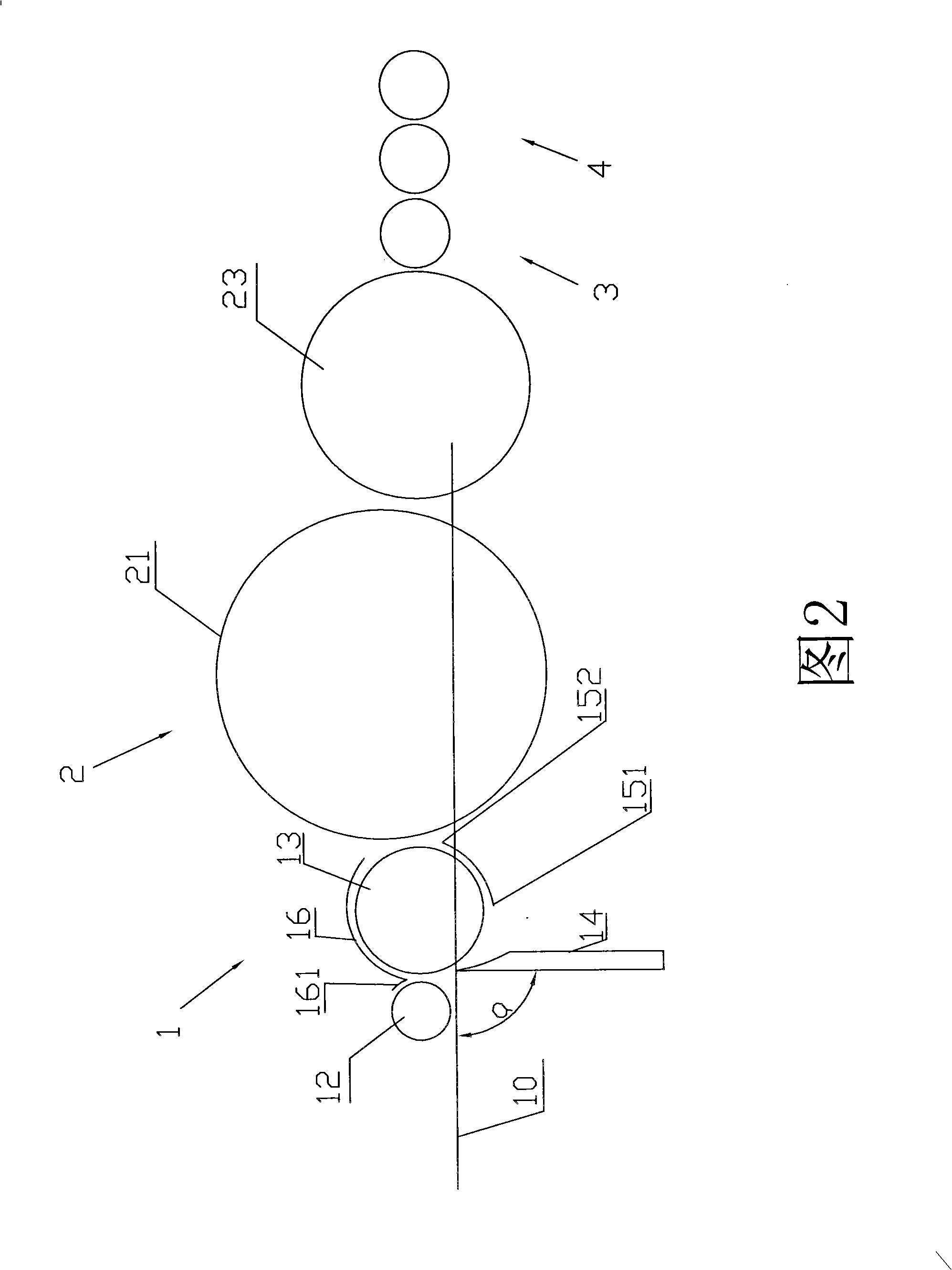

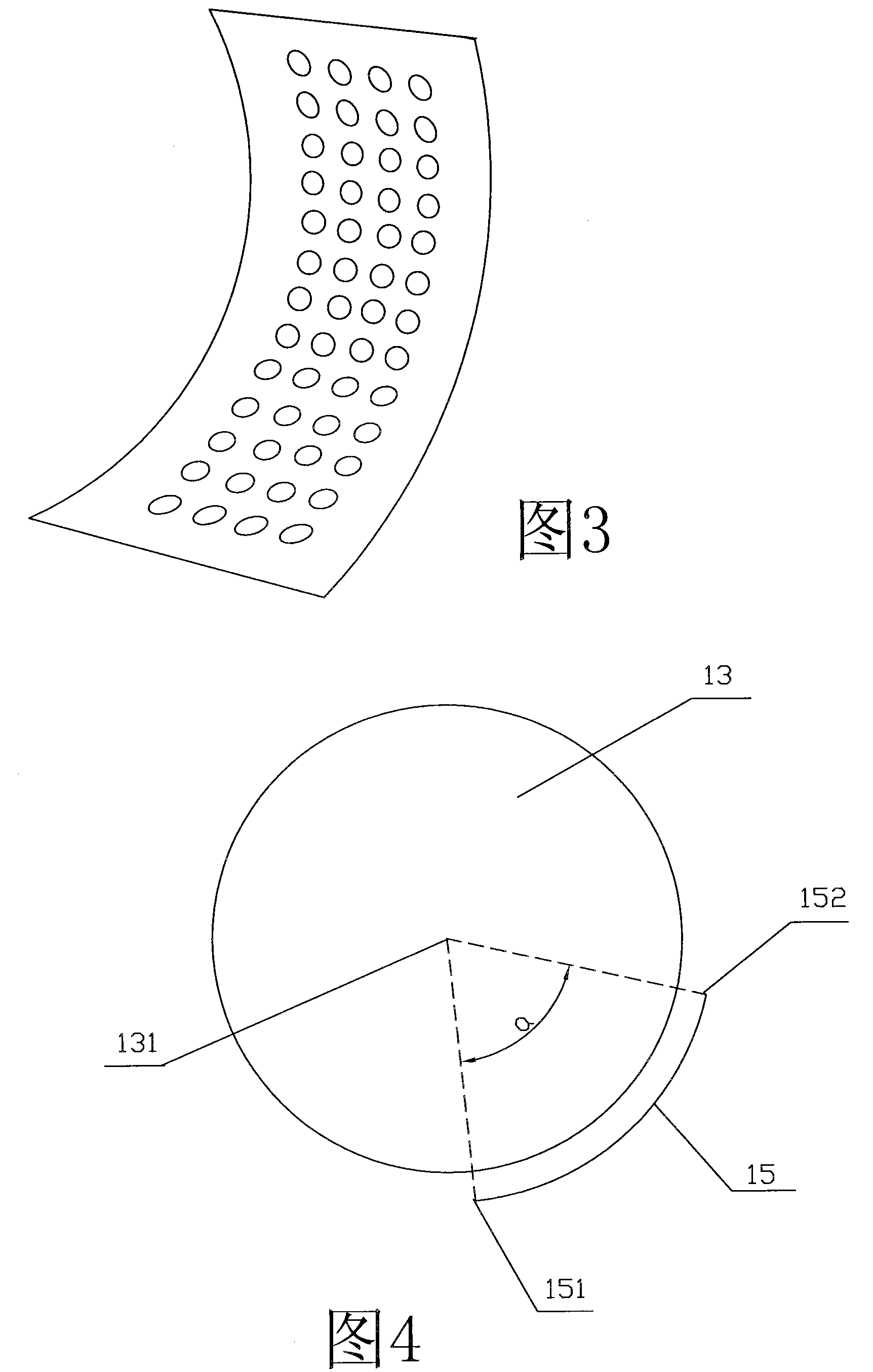

Method used

Image

Examples

Embodiment 1

[0031] The method for blending jute and cotton fiber of the present embodiment with a blending ratio of 71:29 comprises the following steps: 1. opening and cleaning; 2. carding in a carding room, the relative humidity in the carding room is 75%, and the Cover plate type carding machine, the licker-in speed in the carding machine is 800r / min; The cylinder speed in the carding machine is 280r / min; The ratio of the linear speed of the cylinder and the licker-in roller surface is 1.4: 1; ③ draw in the drawing room, the relative humidity in the drawing room is 75%; ④ use air spinning in the air spinning room, the relative humidity in the air spinning room is 85%; 5. be 60 ℃ in temperature, be 15 hours setting under the setting condition of 100% relative humidity, make the blended yarn that jute and cotton fiber blending ratio are 71:29. The performance of the jute blended yarn spun in the present embodiment is as shown in table 1. The properties of the jute blended yarn spun in th...

Embodiment 2

[0037] The method for blending jute and cotton fiber of the present embodiment at a blending ratio of 65:35 comprises the following steps: 1. opening and cleaning; 2. carding in a carding room, the relative humidity in the carding room is 80%, and the Cover plate type carding machine, the licker-in speed in the carding machine is 820r / min; The cylinder speed in the carding machine is 330r / min; The ratio of the linear speed of the cylinder and the licker-in roller surface is 1.6: 1; ③ draw in the drawing room, the relative humidity in the drawing room is 80%; ④ use air spinning in the air spinning room, the relative humidity in the air spinning room is 90%; 5. be 75 ℃ in temperature, be that setting is 12 hours under the setting condition of 90% relative humidity, the blended yarn that made jute and cotton fiber blending ratio is 65: 35. The performance of the jute blended yarn spun in the present embodiment is as shown in table 1.

[0038] The flat carding machine adopted in ...

Embodiment 3

[0041]The method for blending jute and cotton fiber of the present embodiment at a blending ratio of 90:10 comprises the following steps: 1. opening and cleaning cotton; 2. carding in a carding room, where the relative humidity in the carding room is 78%. Cover plate type carding machine, the licker-in speed in the carding machine is 810r / min; The cylinder speed in the carding machine is 300r / min; The ratio of the linear speed of the cylinder and the licker-in roller surface is 1.5: 1; ③ drawing in the drawing room, the relative humidity in the drawing room is 77%; ④ spinning in the air spinning room, the relative humidity in the air spinning room is 88%; 5. be 70 ℃ in temperature, be 95% sizing condition under the setting condition of relative humidity 15 hours, make the blended yarn that jute and cotton fiber blending ratio are 90: 10. The performance of the jute blended yarn spun in the present embodiment is as shown in table 1.

[0042] The flat carding machine adopted in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com