Metal tile plate heat collector

A heat collector and metal technology, applied in the field of metal tile plate heat collectors, can solve the problem of high use threshold and achieve the effect of saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

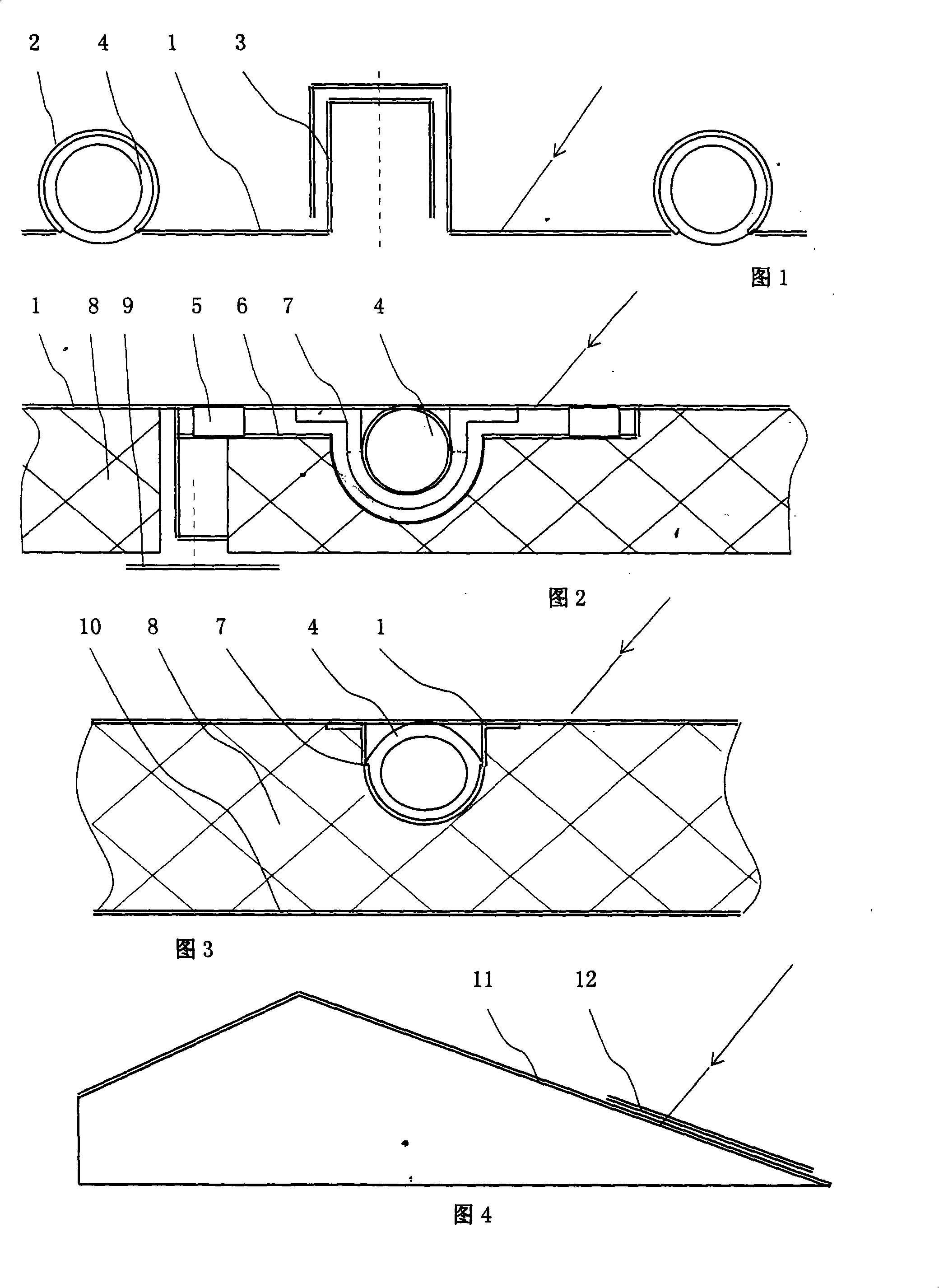

[0013] In Fig. 1, an "Ω"-shaped channel 2 and a tongue-and-groove reinforcing rib 3 are formed on the metal tile 1, and an elastic pipe 4 is arranged in the channel 2. Making channels directly on metal tiles has the advantages of low thermal resistance and high strength. The channel 2 is a closing channel, which makes the embedded elastic pipe not easy to fall off, and is convenient for on-site assembly and replacement. Some adhesive materials can be used to help fix the elastic pipe when using a channel that is not closed, and the use of adhesive materials can further reduce thermal resistance.

[0014] The working principle of the embodiment shown in Fig. 1 is: sunlight shines on the metal tile 1 and turns into heat energy, and the heat energy is transmitted to the elastic pipe 4 through the channel 2 and heats the water in the elastic pipe 4.

[0015] In FIG. 2 , the “Ω” shaped grooved strip 7 constrained by the magnetic block 5 and the magnetic guide 6 is fixed on the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com