Hot air refluxing apparatus and hot air refluxing process for injection molding drier

A hot air recirculation and dryer technology, applied in drying gas layout, dryer, drying and other directions, can solve the problems of hot exhaust gas pollution, high power loss, high cost, etc., to save power loss, reduce health hazards, reduce The effect of injection molding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

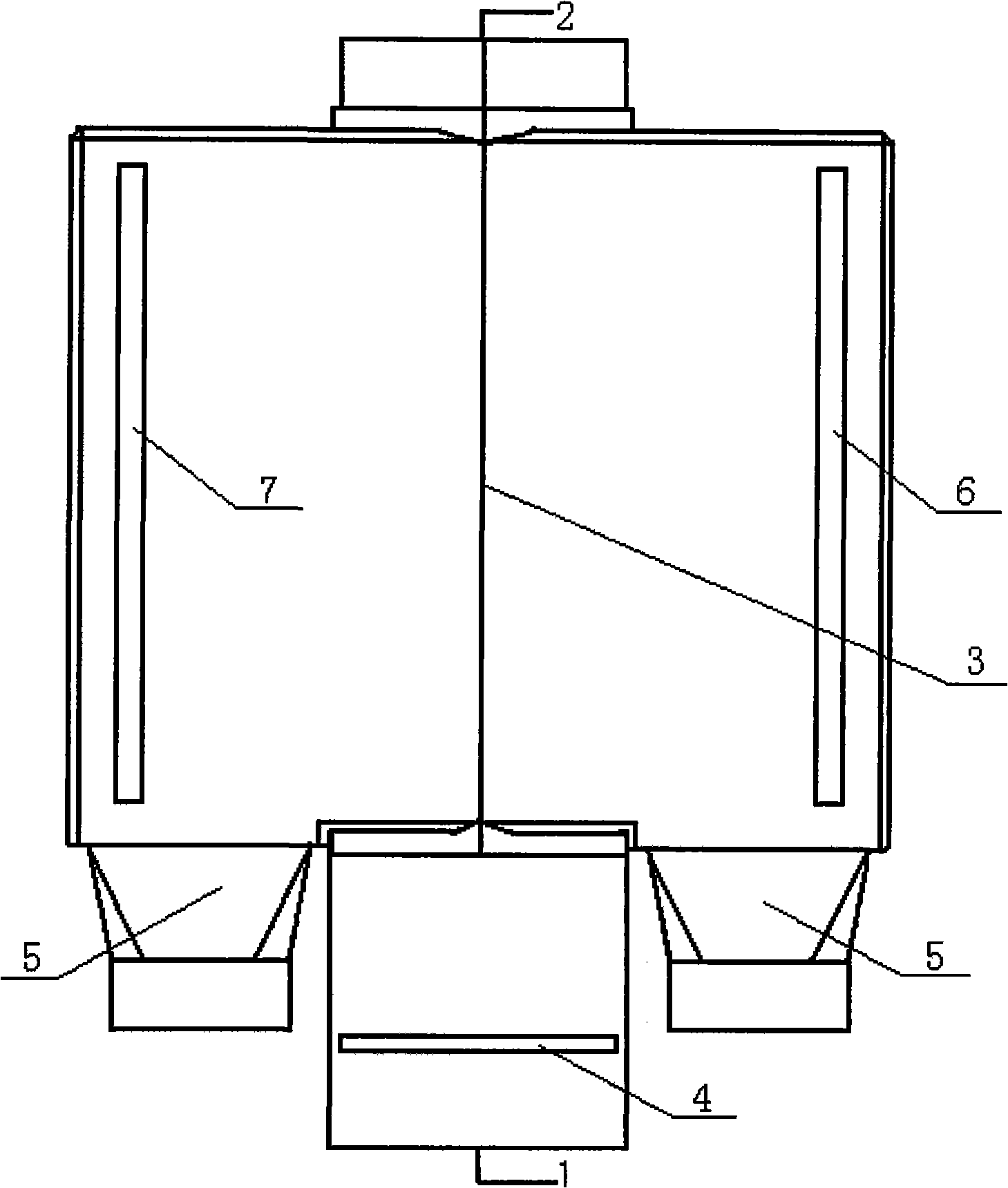

[0019] Such as figure 1 As shown, the hot air return device of the present invention includes a hot gas inlet port 1, a hot gas outlet port 2, a dust removal box 3, an electrostatic generator 4, an impurity recovery device 5, a strong electric field positive electrode 6 and a strong electrode negative electrode 7, and the hot gas inlet port 1 The hot air outlet port 2 is respectively connected to the air outlet and the air inlet of the injection molding dryer. An electrostatic generator 4 is arranged on the side of the hot air inlet port 1, and a metal electrode is arranged in the dust removal box 3. The hot air return device uses the strong force of the metal electrode. The electric field positive electrode 6 and the strong electric field negative electrode 7 shift the charged suspended matter to the two electrode ends. There are two impurity recoverers 5 below the dust removal box 3, which are used to recover the precipitated impurities.

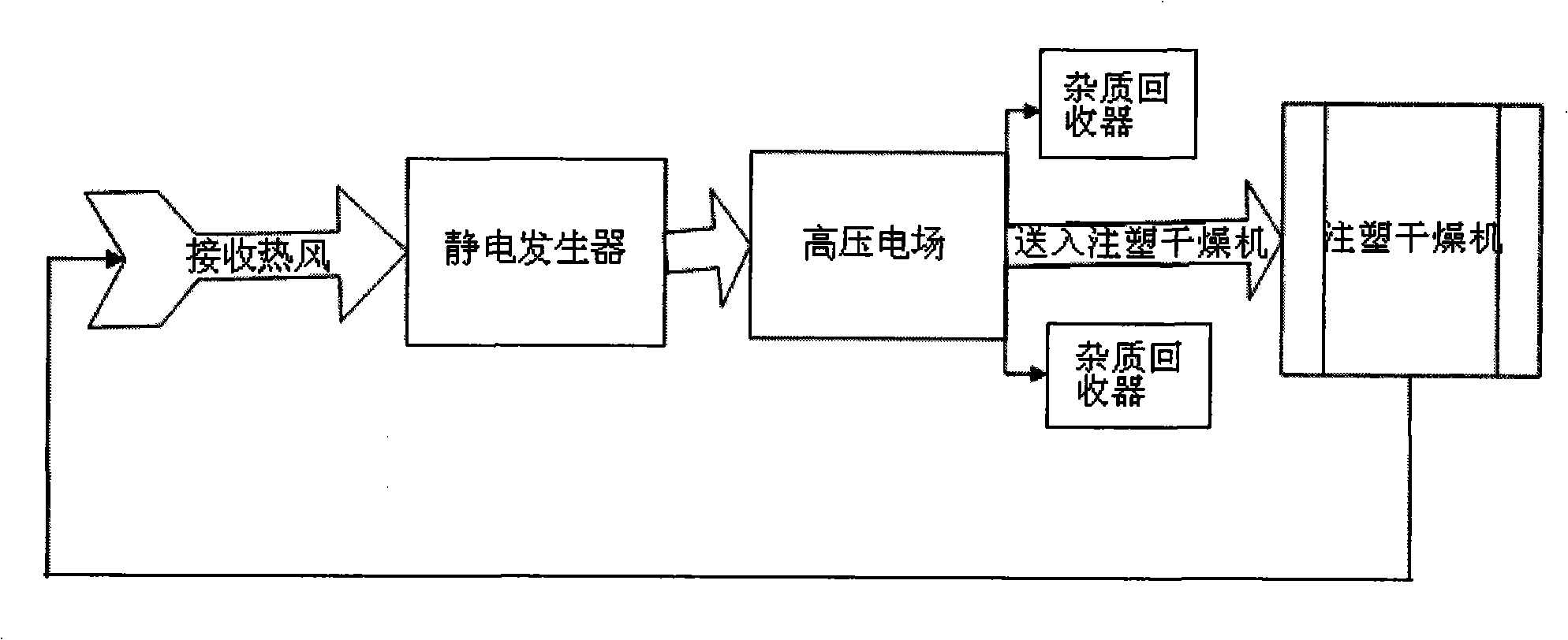

[0020] Such as figure 2 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com