Fixed mounting method of hot melt wax double heating of micro-dimension superconduction tunnel junction

A technology of secondary heating and installation method, applied in geophysical measurement, instrument and other directions, can solve problems such as difficult to remove, difficult to achieve intermediate frequency end point welding, and poor fixing, so as to improve the installation success rate, the installation success rate, and the The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

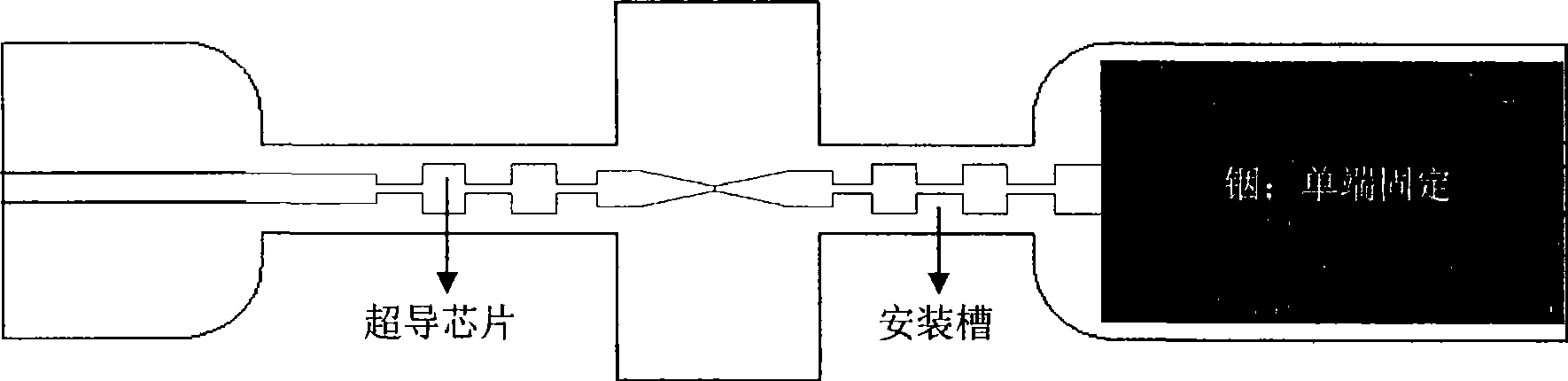

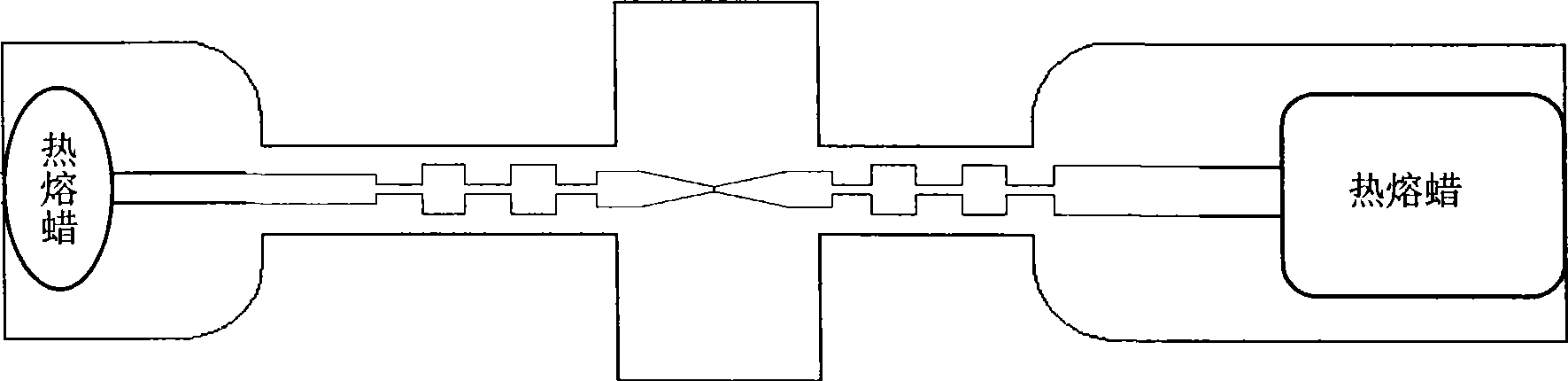

[0037] Embodiment 1, with reference to figure 2 :

[0038] (1) Put the superconducting SIS chip into the installation slot and roughly adjust the position;

[0039] (2) Put a little hot-melt wax on both ends of the chip. At this time, the wax is in solid state. Just lightly put it on the surface of both ends of the chip. The amount of wax is related to the size of the chip. It is larger than the device and equivalent to the width of the groove (because the size of the superconducting device is small, the mass of the wax usually does not exceed one gram);

[0040] (3) Then place the mixer base on the hot plate, and set the temperature of the hot plate at about 100 degrees (10-20 degrees lower than the melting point of wax);

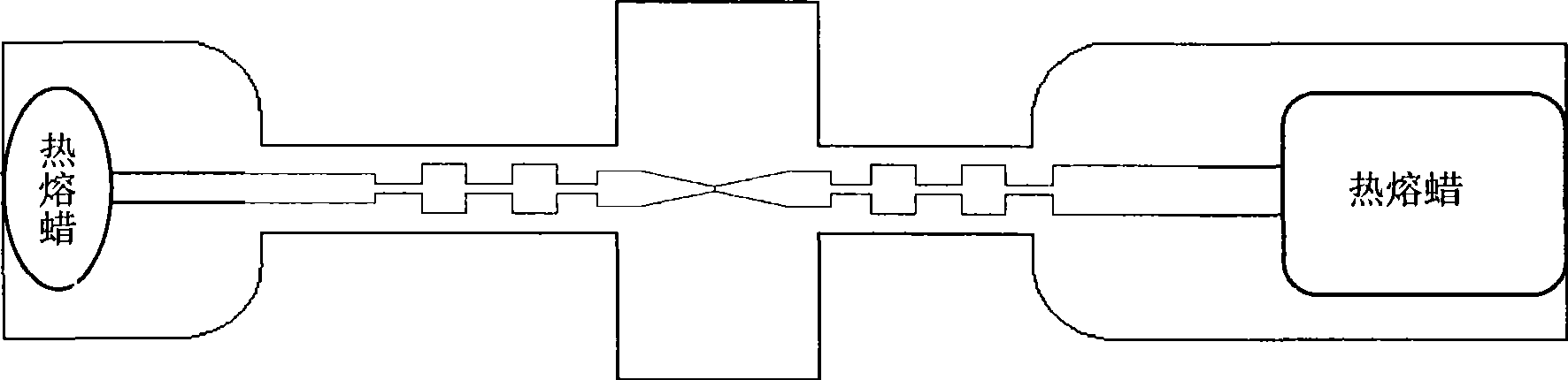

[0041] (4) After the hot melt wax becomes soft (not completely melted at this time), remove the mixer base from the hot plate, and use a thinned toothpick to gently press and move the softened wax so that it can better cover the chip Both ends, and bet...

Embodiment 2

[0047] Example 2 is basically the same as Example 1, but the hot melt wax (wax) used is: BS-120N series hot melt adhesive: softening point 115-125°C, operating temperature 160-190°C.

Embodiment 3

[0048] Example 3 is basically the same as Example 1, but the hot-melt wax (wax) used is: BL-58B series hot-melt adhesive: softening point 88°C, operating temperature 160-180°C. Compared with the former, it has strong adhesion, good toughness and good low temperature resistance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com