Permanent magnet type vacuum circuit-breaker

A vacuum circuit breaker, permanent magnet technology, applied in the direction of high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problem of short force arm, etc., achieve simple and easy operation, ensure stability and reliability, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (Example 1, permanent magnet vacuum circuit breaker)

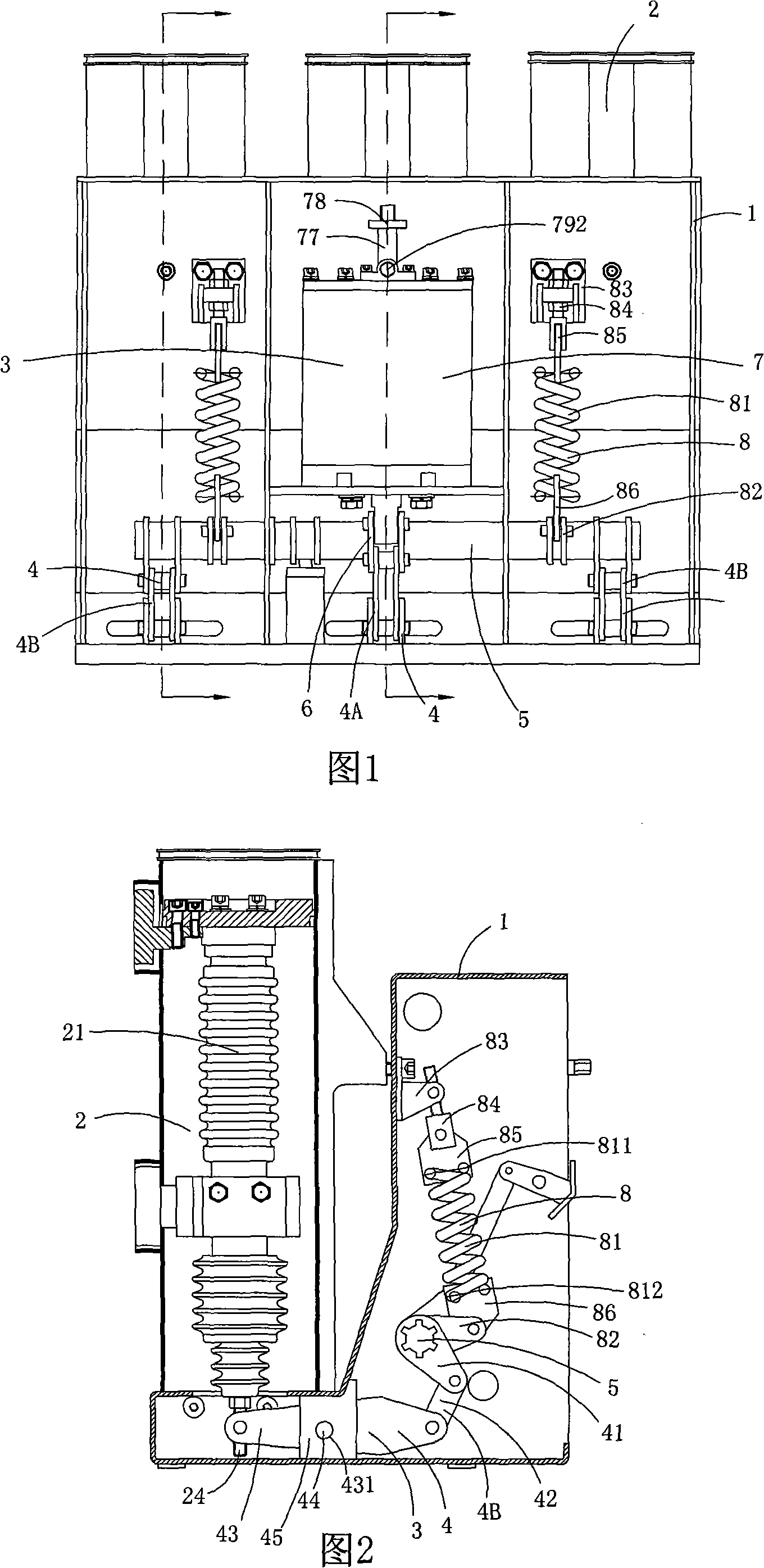

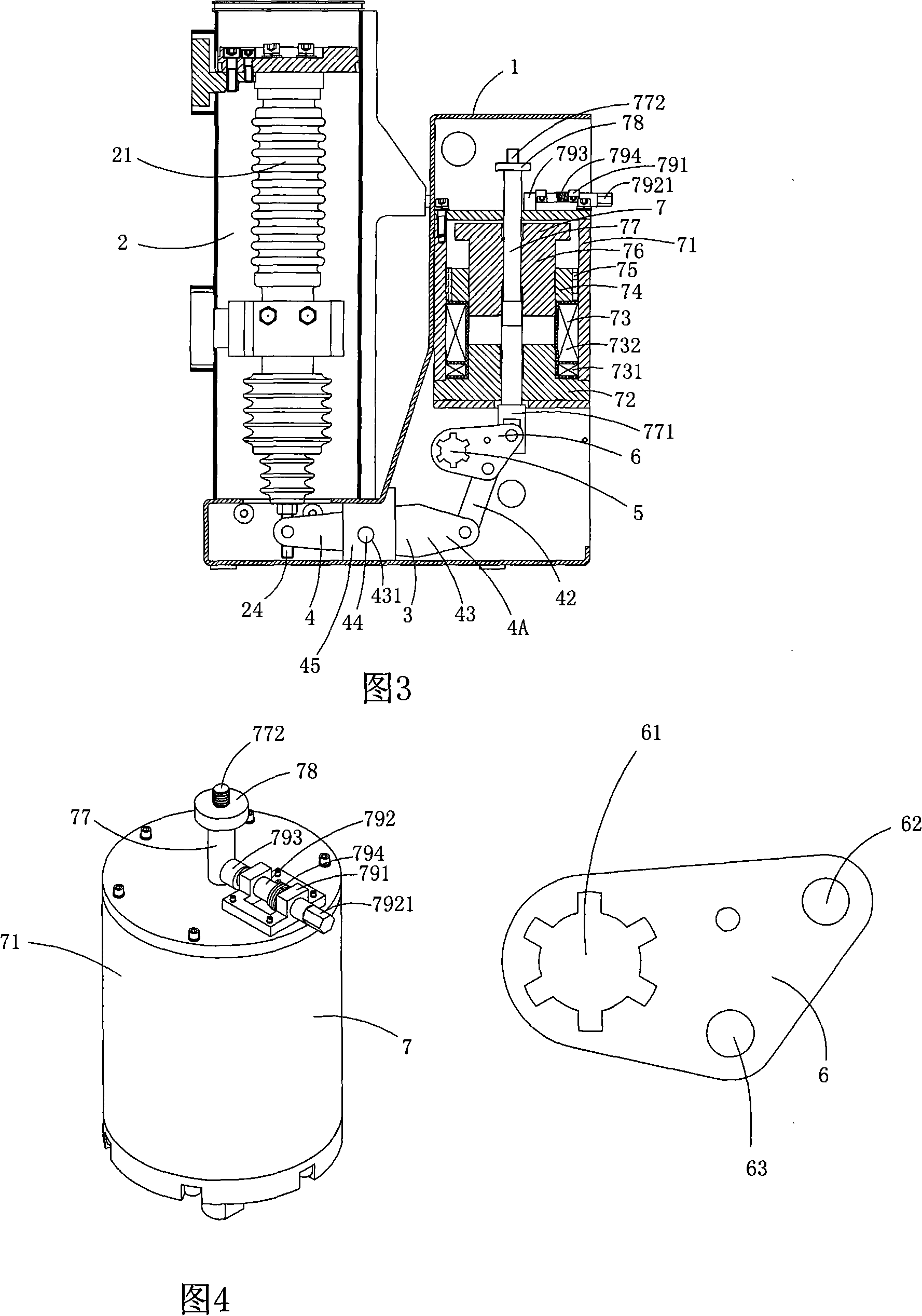

[0025] Figure 1 to Figure 4 A specific embodiment of the invention is shown; wherein, figure 1 It is a structural schematic diagram of the present invention, figure 2 yes figure 1 The schematic diagram of the cross-sectional structure of the permanent magnet vacuum circuit breaker along the line A-A; image 3 yes figure 1The schematic diagram of the cross-sectional structure of the permanent magnet vacuum circuit breaker along the line B-B; Figure 4 yes figure 1 A schematic diagram of a three-dimensional structure of the permanent magnet drive mechanism in the permanent magnet vacuum circuit breaker shown; Figure 5 yes image 3 A structural schematic diagram of the driving crank arm in the permanent magnet vacuum circuit breaker shown.

[0026] See Figure 1 to Figure 5 , this embodiment is a permanent magnet high voltage vacuum circuit breaker, including a circuit breaker housing 1, three vacuum circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com