DC great current deicing apparatus with static state reactive compensation function

A static reactive power compensation, high current technology, applied in reactive power compensation, output power conversion devices, AC power input conversion to DC power output, etc., can solve problems such as difficult conversion control, reduce supporting costs, and achieve reasonable structure. , switch the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

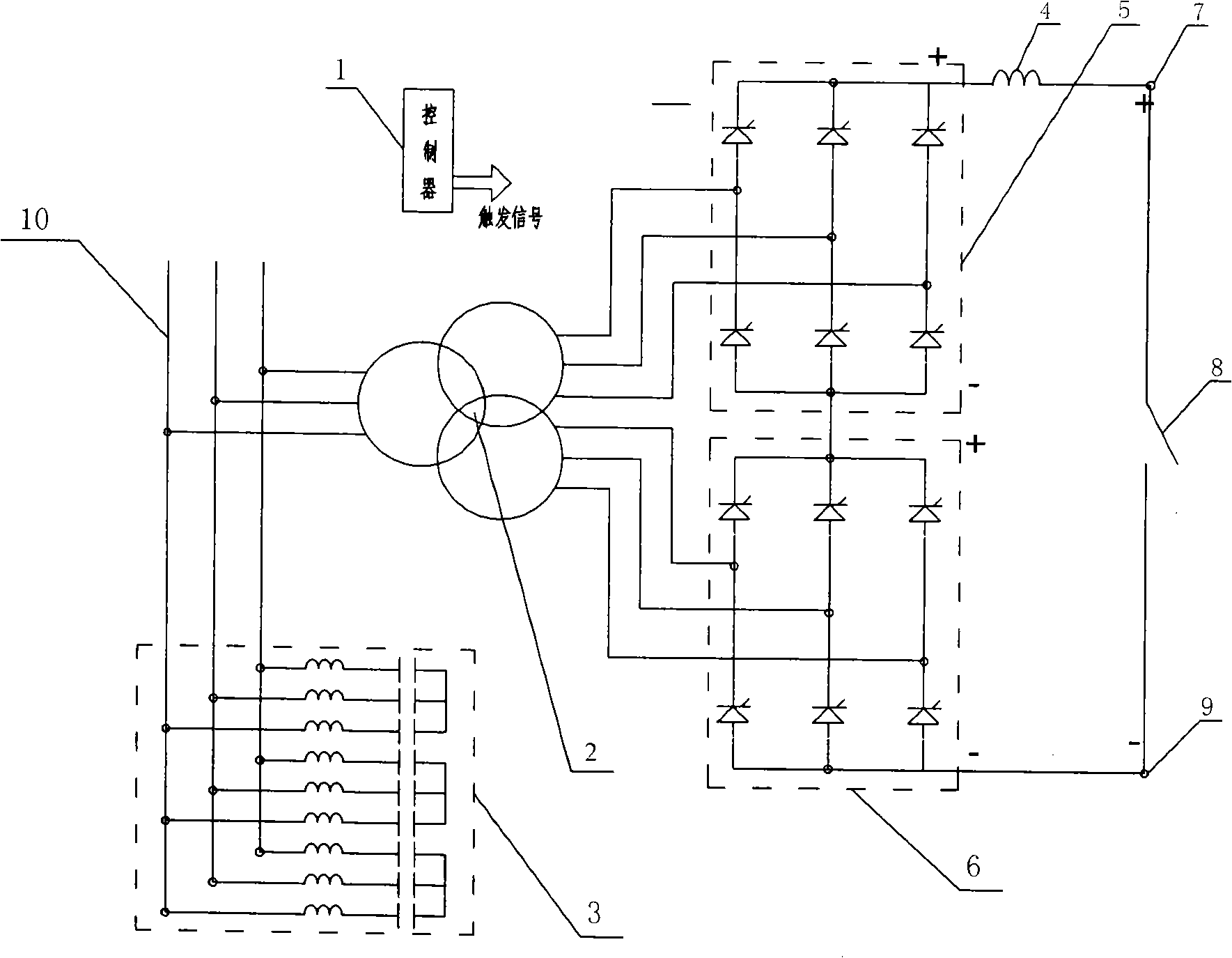

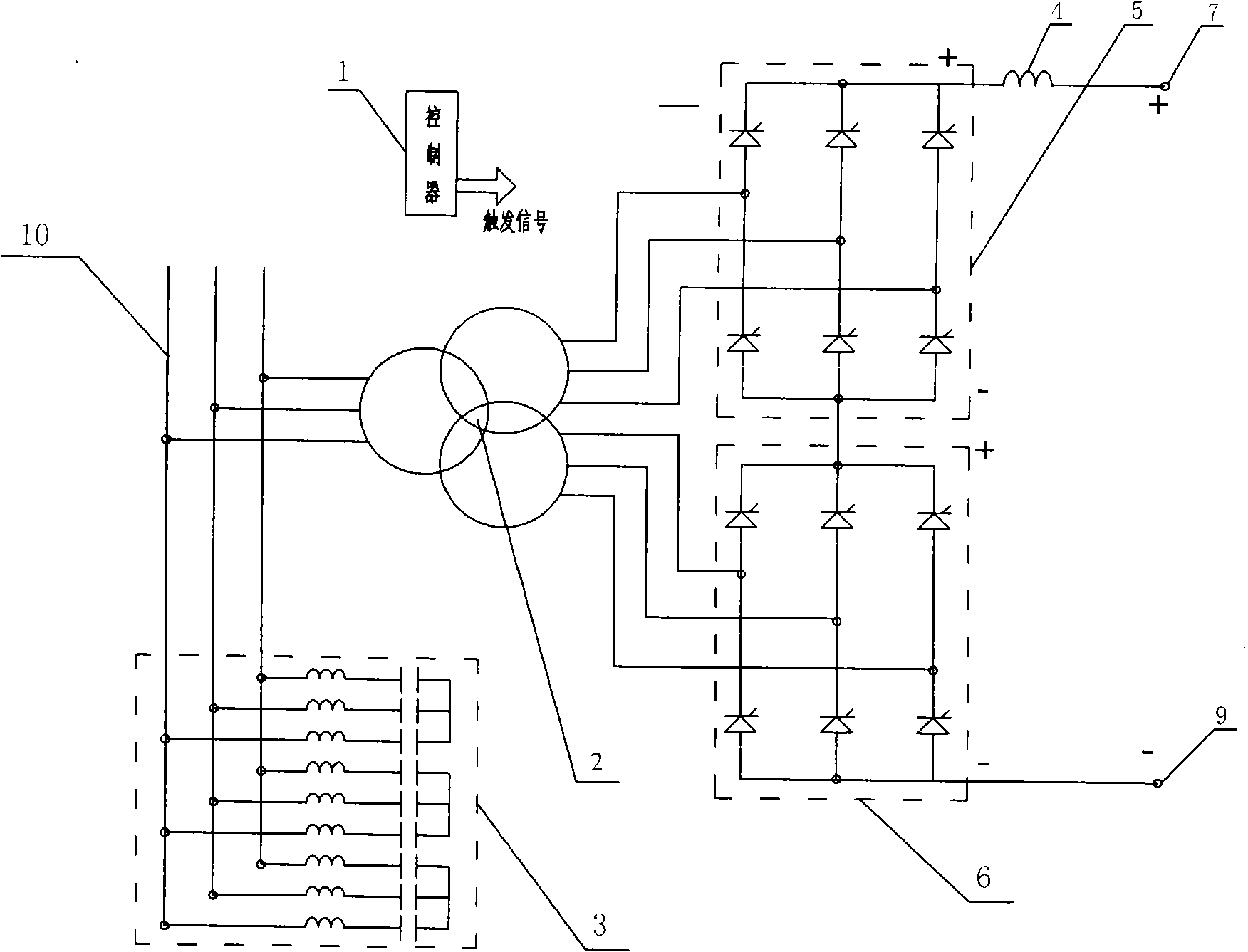

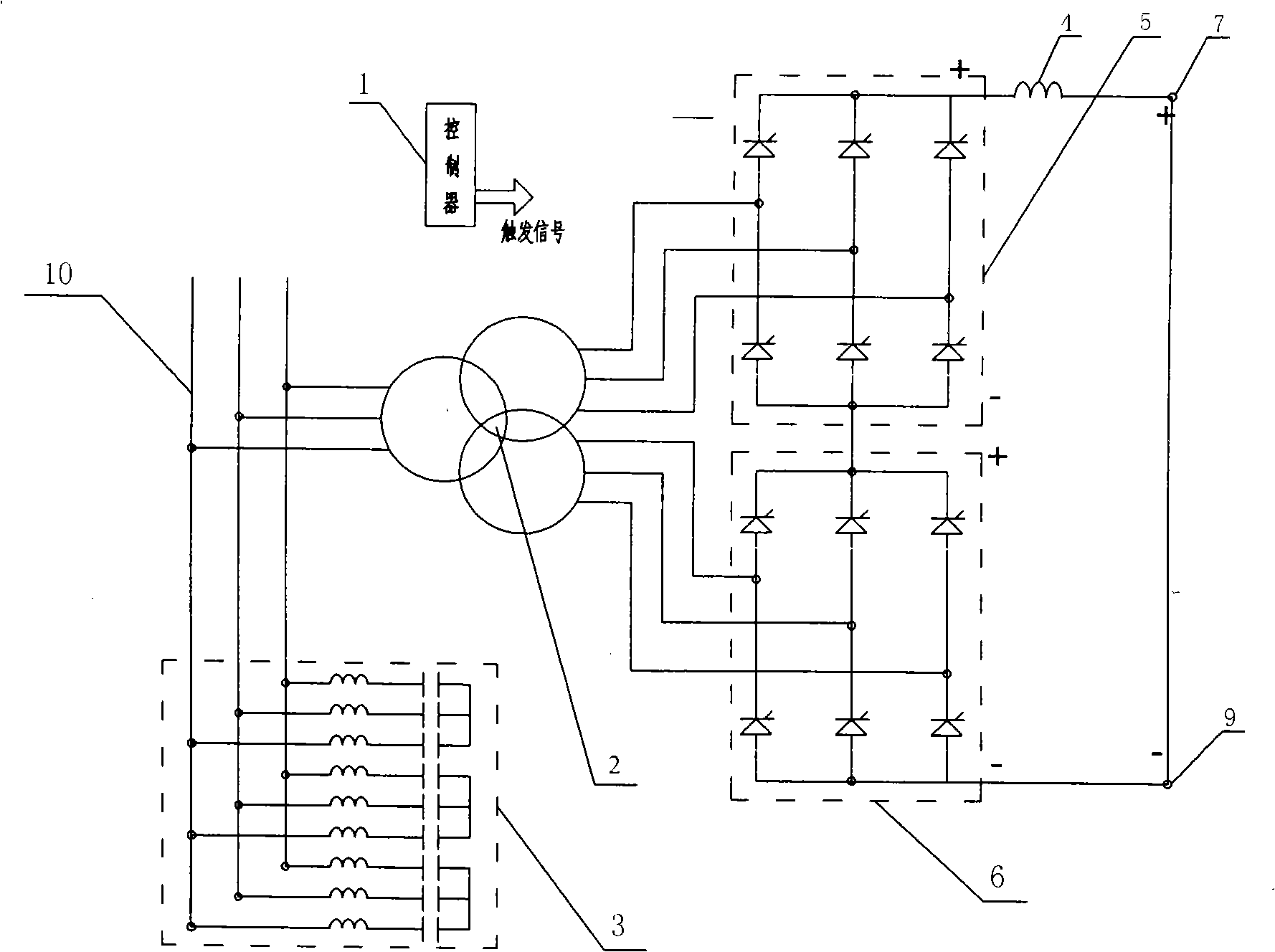

[0020] The present invention will be further described below in conjunction with the accompanying drawings:

[0021] like figure 1 Shown is a DC high-current ice melting device with static reactive power compensation function. The primary side of the three-winding rectifier transformer 2 is connected to the three-phase bus in parallel, and the two secondary sides are connected in star and delta respectively. 30° and the same amplitude, and the two secondary sides are respectively connected to the middle point of the positive-end three-phase high-voltage high-current thyristor valve 5 and the negative-end three-phase high-voltage high-current thyristor valve 6 . The main body of each phase is a series of thyristor valves, and each phase of the thyristor valve has three external electrical connection terminals. , respectively positive, negative and middle points, the middle point is the AC side, the middle point and the positive and negative thyristors connected in series are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com