Total biological degradation nonwoven cloth for medical treatment/industry and preparing technique thereof

A biodegradation and production process technology, applied in paper/cardboard layered products, layered products, chemical instruments and methods, etc., can solve the problems of poor finishing, high cost of harmless waste treatment, and non-woven production costs. Advanced problems, to achieve the effect of low production cost, low cost characteristics, and strong use comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

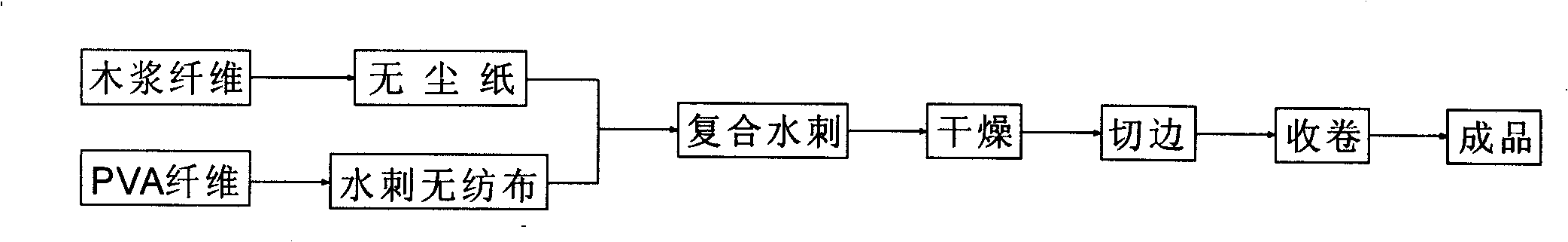

[0014] The fully biodegradable medical / industrial protective nonwoven fabric described in the present invention has a layered structure, including a wood pulp fiber layer and a spunlace nonwoven fabric base layer, and wood is compounded on one surface of the spunlace nonwoven fabric base layer. Pulp fiber layer.

[0015] The production process of the present invention is as follows: first make the dust-free paper from the wood pulp fiber, and make the PVA spunlace non-woven fabric from the PVA fiber, and then use the spunlace non-woven fabric production line to compound the dust-free paper on the PVA spunlace non-woven fabric. One side of the cloth is dried, trimmed, and rolled to obtain a finished product with an average grammage of 35-300 grams per square meter. The production process described is a single-sided composite process.

[0016] When producing dust-free paper, the amount of wood pulp fiber is controlled at 5-100 g / m2; when producing PVA non-woven fabrics, the amo...

Embodiment 2

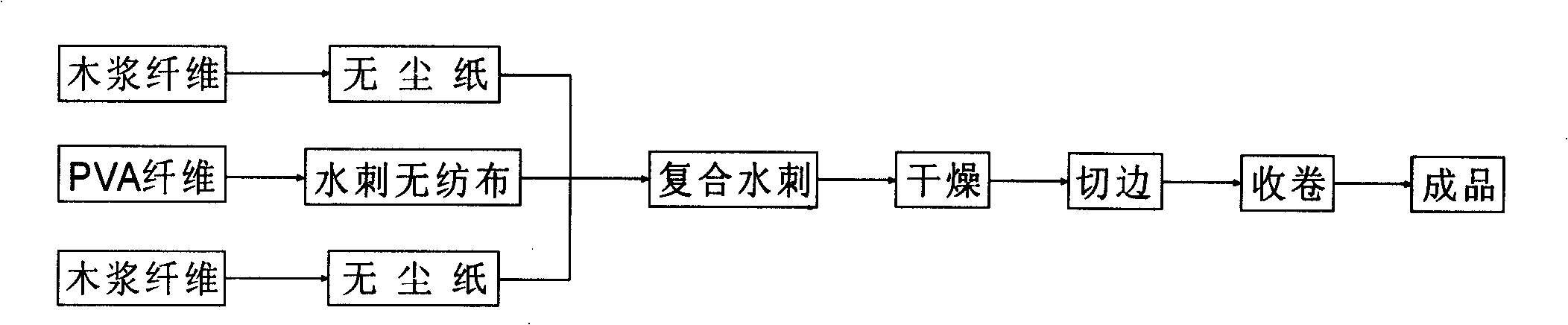

[0019] The completely biodegradable medical / industrial protective non-woven fabric described in the present invention has a hierarchical structure, including a wood pulp fiber layer, a spunlace non-woven fabric base cloth layer, a wood pulp fiber layer, and two spunlace non-woven fabric base cloth layers. The surface is compounded with a wood pulp fiber layer.

[0020] The production process of the present invention is as follows: first make the dust-free paper from the wood pulp fiber, and make the PVA spunlace non-woven fabric from the PVA fiber, and then use the spunlace non-woven fabric production line to compound the dust-free paper on the PVA spunlace non-woven fabric. The two surfaces of the cloth are dried, trimmed and rolled to obtain the finished product, and the average gram weight of the finished product is 35-300 grams per square meter. The production process described is a double-sided composite process.

[0021] When producing dust-free paper, the amount of woo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com