Back heating type two-stage thermochemistry adsorption cooling cycle system based on voltage transformation desorption technique

A chemical adsorption and adsorption refrigeration technology, which is applied in refrigerators, refrigeration and liquefaction, climate change adaptation, etc., can solve the problems of limiting the temperature range of waste heat utilization and high desorption temperature of adsorbents, so as to reduce the demand for heat source heat and expand the utilization range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

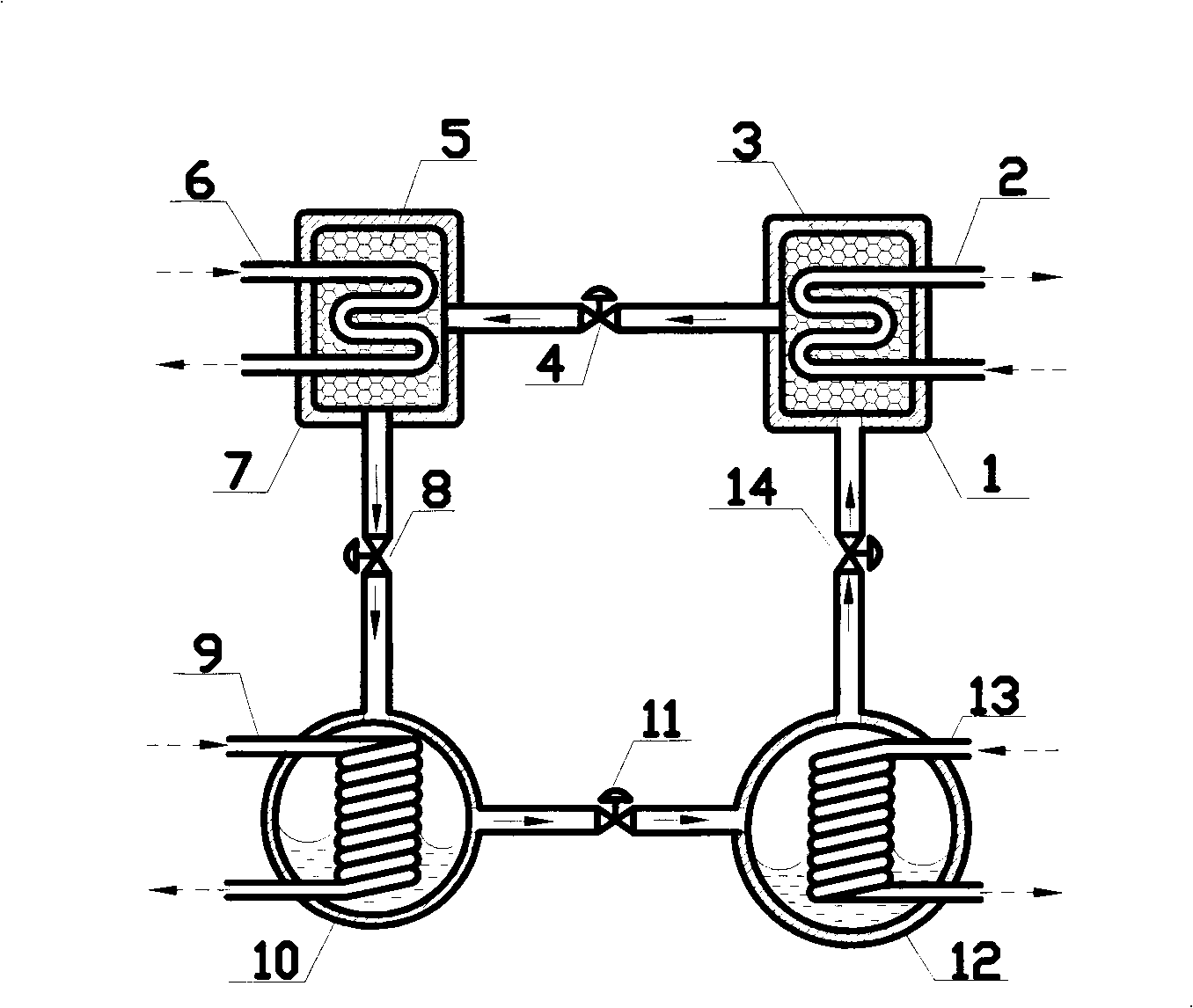

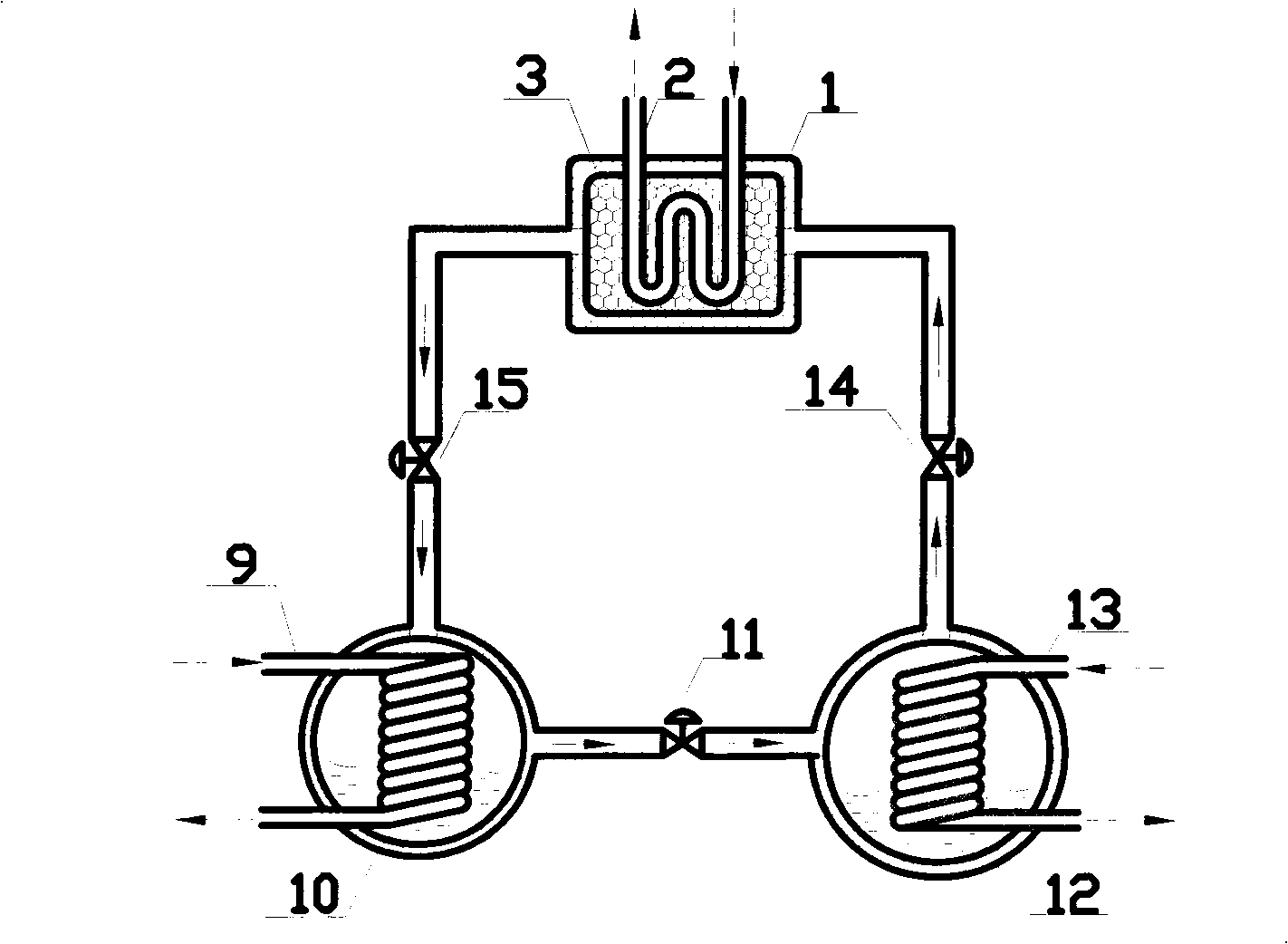

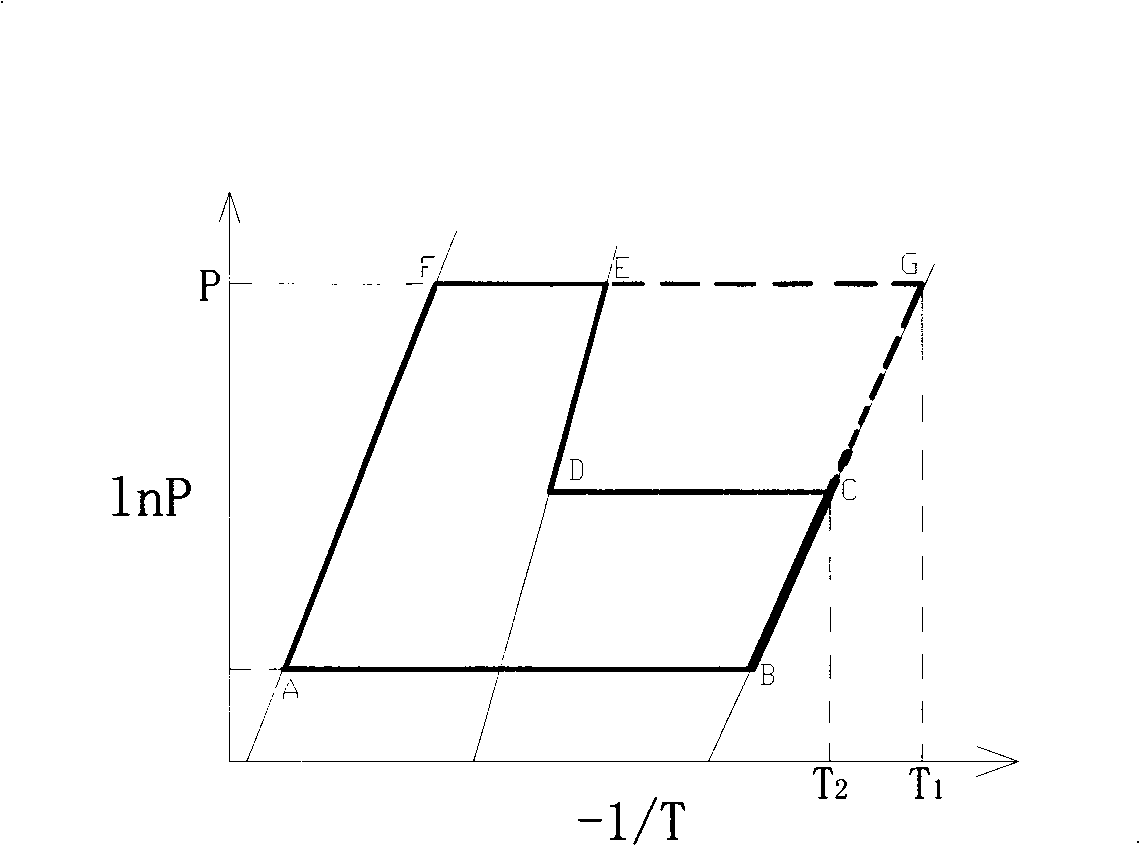

[0025] Such as figure 1 As shown, this embodiment includes a main reactor 1, a main reactor heating and cooling coil 2, a high-temperature reaction chemical adsorbent 3, an intermediate regulating valve 4, a medium-temperature reaction chemical adsorbent 5, and an auxiliary reactor heating and cooling coil 6 , Auxiliary reactor 7, auxiliary regulating valve 8, condenser heat exchange coil 9, condenser 10, throttle valve 11, evaporator 12, evaporator heat exchange coil 13, main regulating valve 14.

[0026] The outlet of main reactor 1 is connected to the inlet of int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com