Diffusion brightening film sheet

A technology of brightness-enhancing film and diffusing particles, which is applied in optics, instruments, nonlinear optics, etc., can solve the problems of increased production cost of backlight module 1, and achieve the effects of simplifying the structure, reducing bright streaks, and improving positive brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

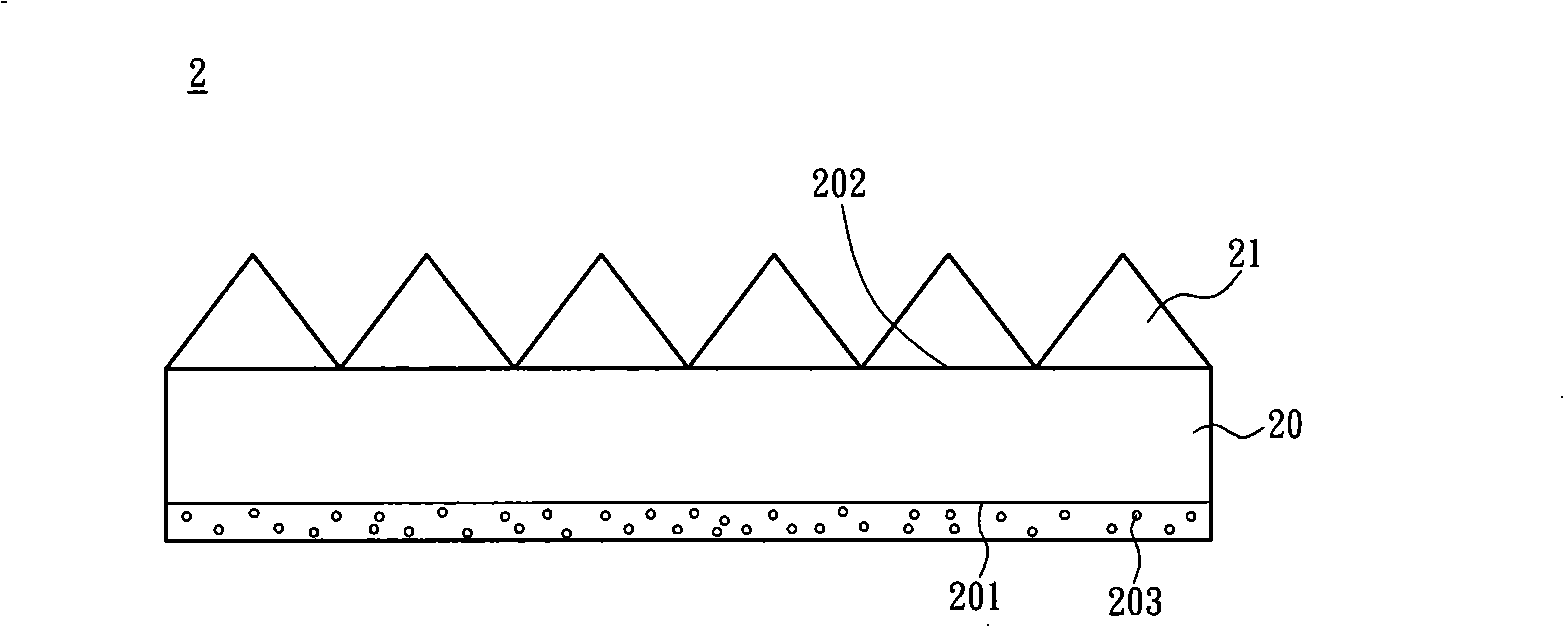

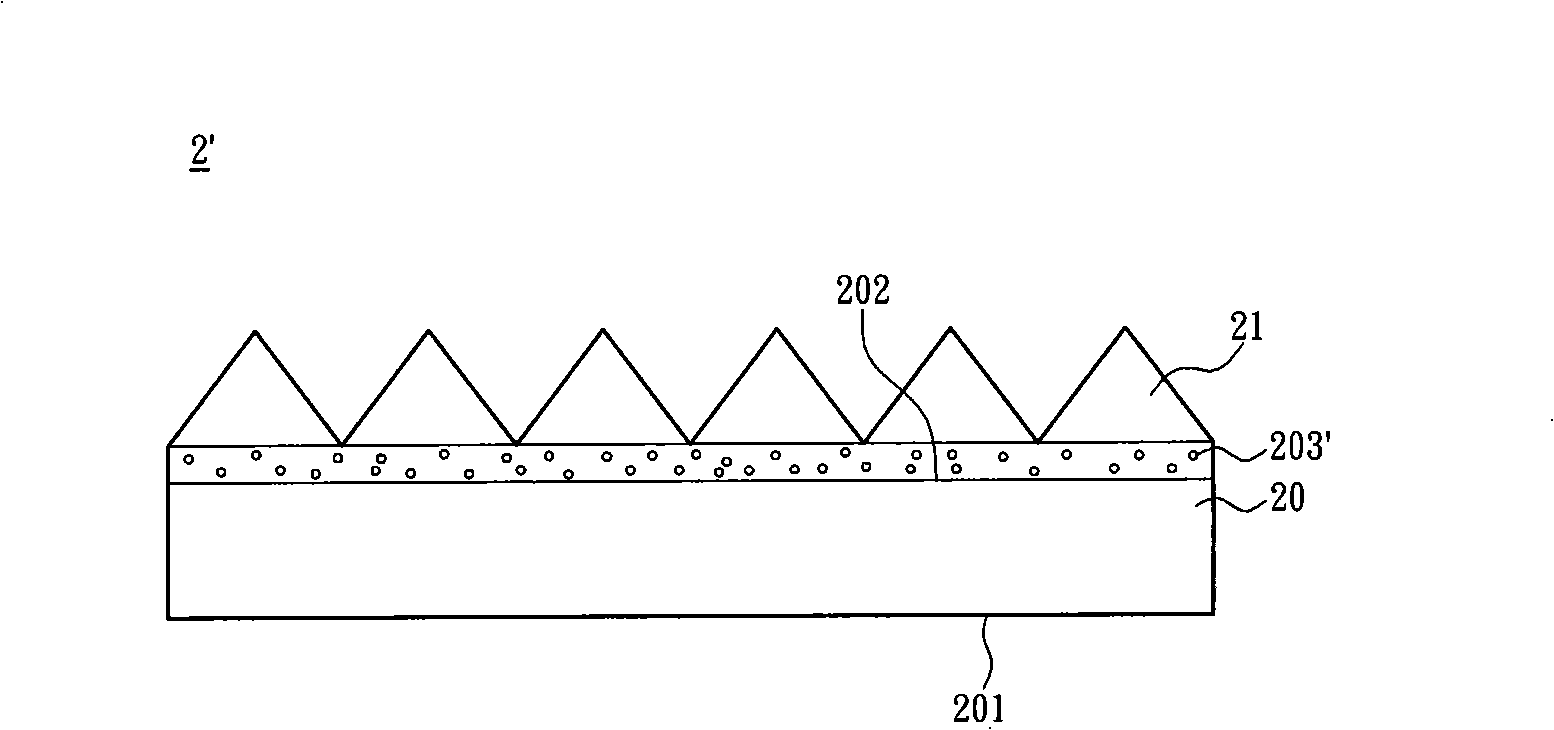

[0050] see figure 2 As shown, a diffusion enhancement film 2 according to the first embodiment of the present invention includes a substrate 20 and a prism structure 21 . Wherein, the diffusion enhancement film 2 can be arranged in a backlight module.

[0051] The substrate 20 has a first surface 201 and a second surface 202 opposite to each other, the first surface 201 and the second surface 202 are opposite to each other, and the material of the substrate 20 is transparent polyethylene terephthalate Polyethylene Terephthalate (PET) or polycarbonate. The substrate 20 has a diffusion material 203 and is disposed on the first surface 201 . In this embodiment, the diffusion material 203 is, for example, diffusion particles such as titanium dioxide or silicon dioxide mixed with an adhesive colloid (binder) and disposed on the first surface 201, wherein the diffusion material 203 can also refer to the diffusion particles alone or in other ways It is disposed on the first surfa...

no. 2 example

[0056] see Figure 5 As shown, a diffusion enhancement film 3 according to the second embodiment of the present invention includes a substrate 30 and a prism structure 31, the substrate 30 has a first surface 301 and a second surface 302, the first surface 301 and the The second surface 302 is disposed opposite, and the prism structure 31 is disposed on the second surface 302 . In this embodiment, the diffusion material 303 is directly doped or mixed into the substrate 30 by doping or mixing.

[0057] see Figure 6 As shown, the diffusion material 303 of another diffusion enhancement film 3' of the present invention, in addition to being incorporated into the substrate 30, the diffusion enhancement film 3' can also be provided with the diffusion material 303' on the first surface 301 and / or the second surface 302. At Figure 6 In the example, the diffusion material 303 is mixed into the substrate 30 and the diffusion material 303' is disposed on the first surface 301 and t...

no. 3 example

[0060] see Figure 8 As shown, another diffusion enhancement film 4 according to the third embodiment of the present invention includes a substrate 40 and a prism structure 41 . The substrate 40 has a first surface 401 and a second surface 402 oppositely disposed. In this embodiment, the first surface 401 is a rough surface, which is formed on the first surface 401 by, for example, sandblasting or a chemical agent surface treatment, and the prism structure 41 is disposed on the second surface 402 . When the light from the light source passes through the first surface 401 , the rough surface has a diffusion effect to make the light from the light source uniform.

[0061] see Figure 9 As shown, in addition to the first surface 401 being a rough surface, the second surface 402 or the first surface 401 and the second surface 402 can also be a rough surface at the same time. At Figure 9 Among them, the first surface 401 and the second surface 402 of the diffusion enhancement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com