Electrically bent endoscope device

An endoscope and bending technology, which is applied in the field of electric bending endoscope devices, can solve the problems of complicated changing operation of the operating part and no correction of output signal differences, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

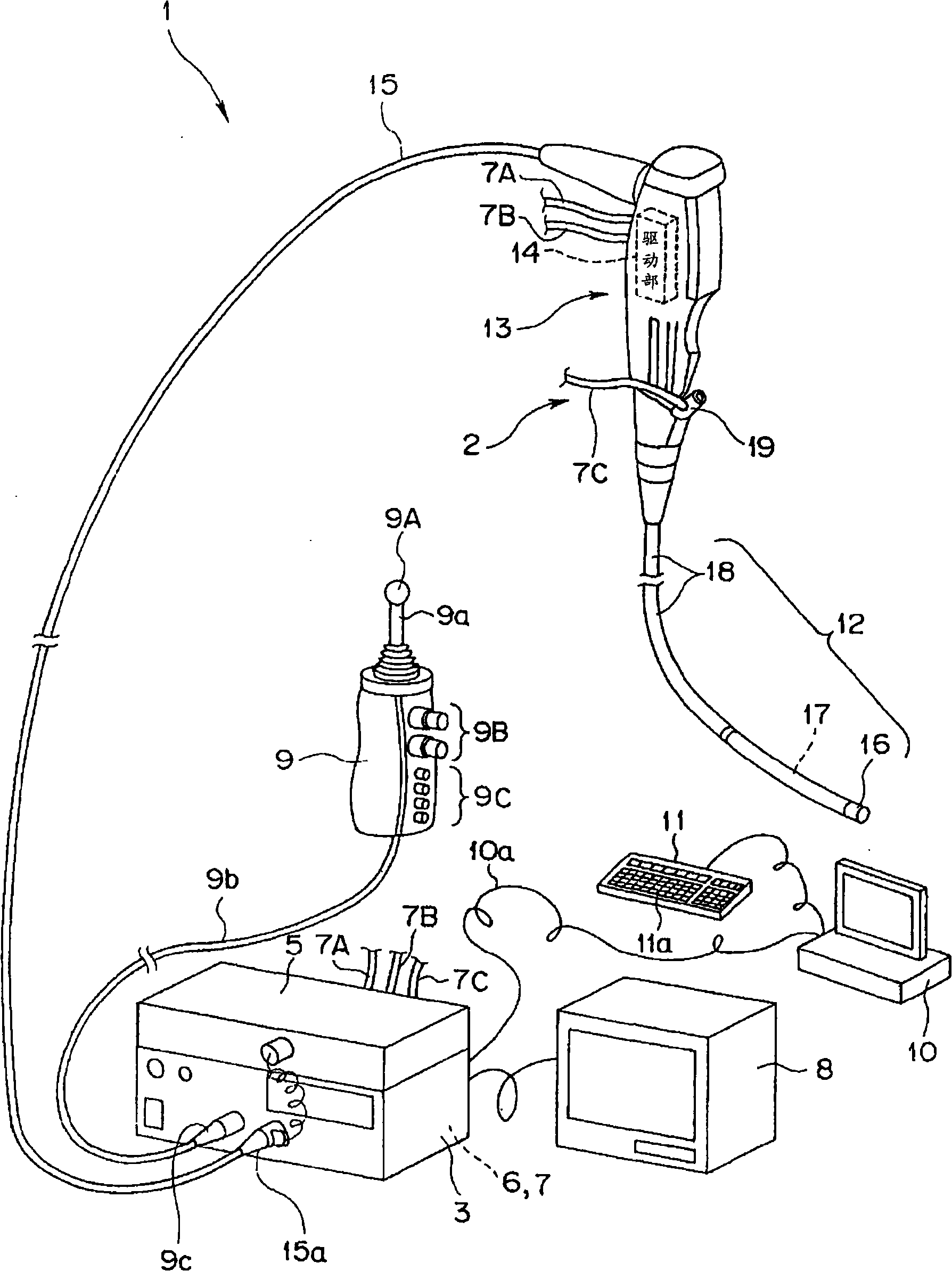

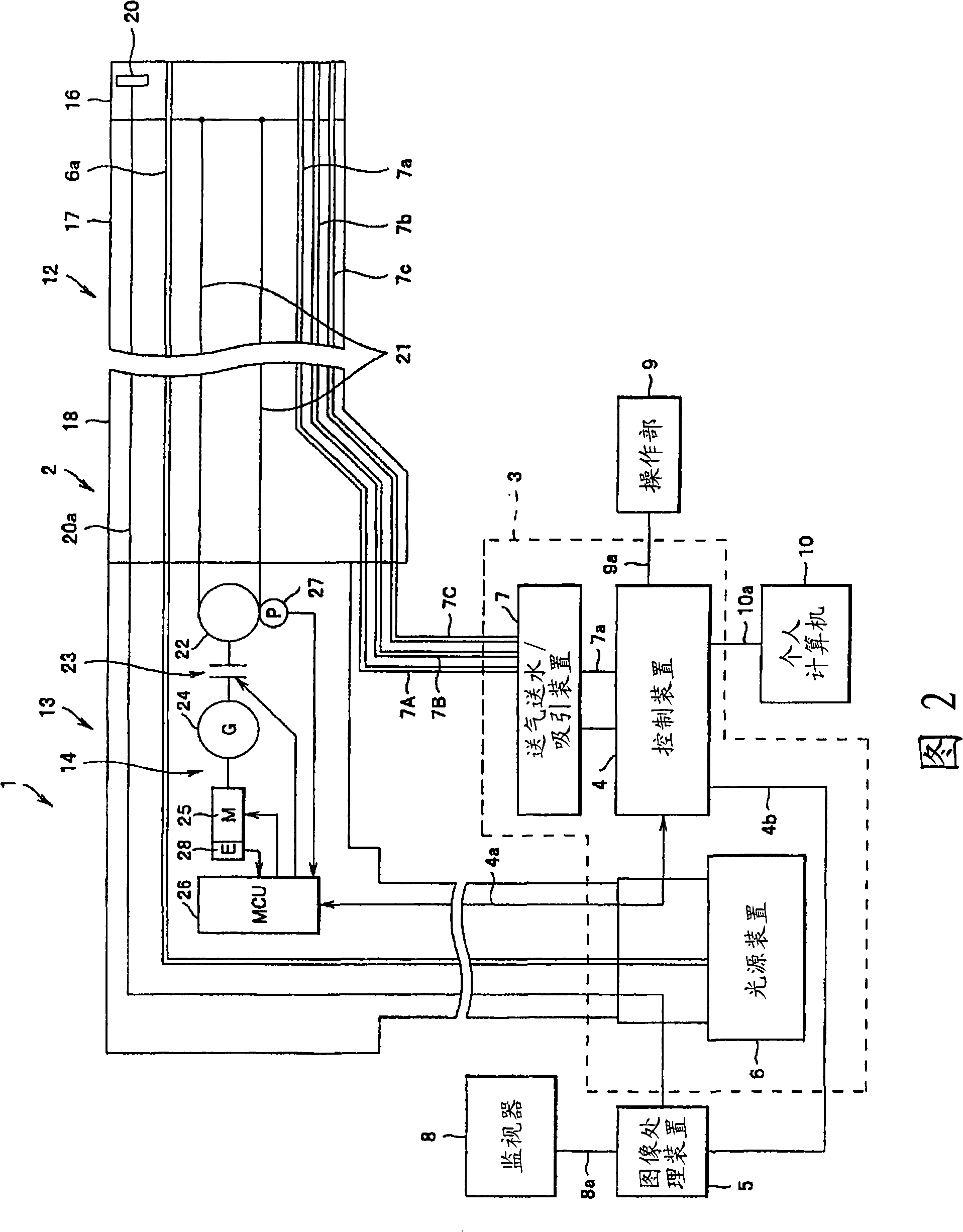

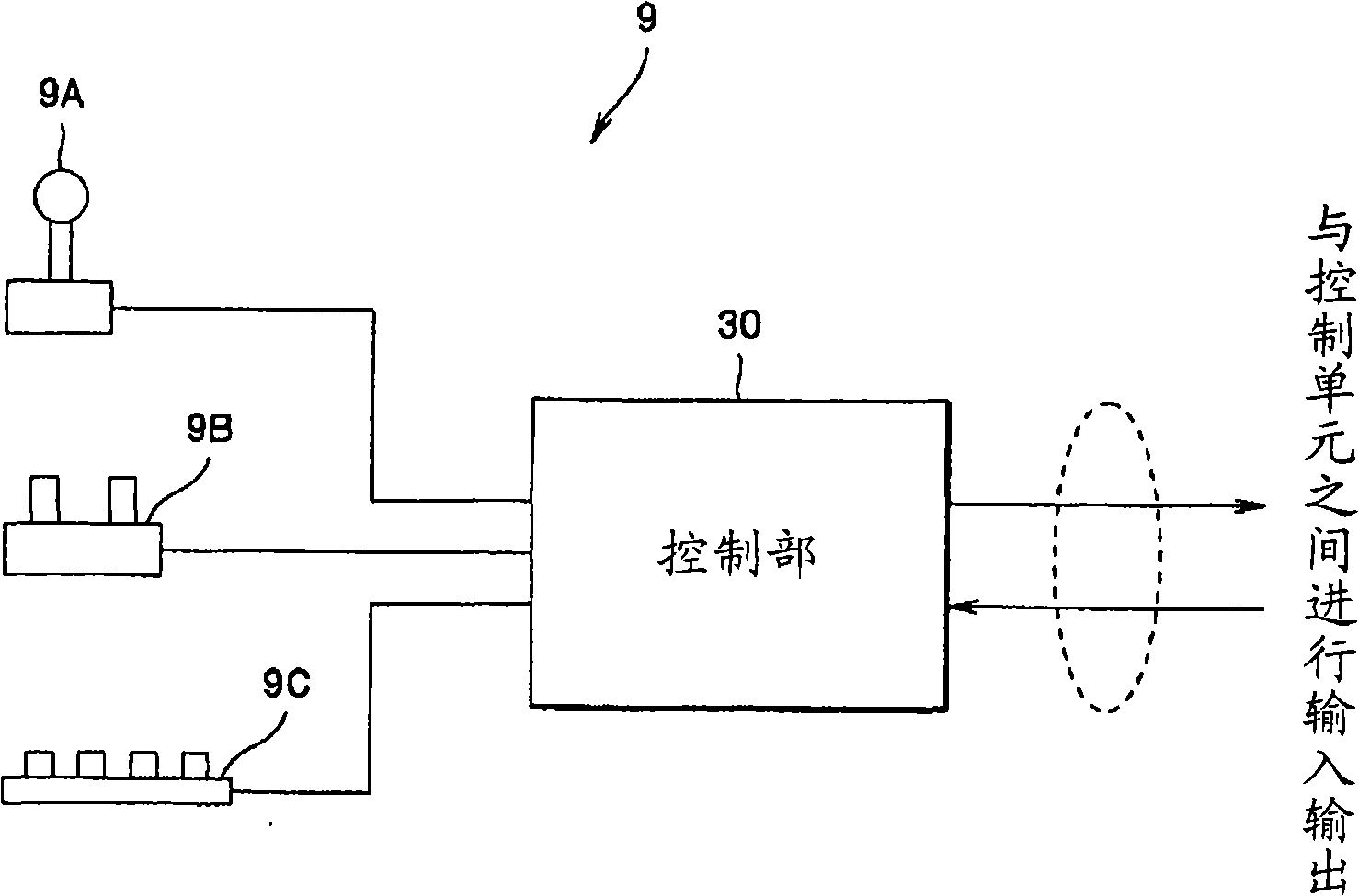

[0048] figure 1 Embodiment 1 of the electric bending endoscope device of the present invention will be described with FIG. 2 . figure 1 It is a system configuration diagram of the electric bending endoscope device. Figure 2 is shown figure 1 A diagram of the schematic structure of the motorized bending endoscope device.

[0049] Such as figure 1 As shown in FIG. 2, the electric bending endoscope device 1 of embodiment 1 has: an electric bending endoscope (hereinafter referred to simply as endoscope) 2; a control unit 3; The image signal transmitted by the signal cable 20a extending from the above-mentioned imaging element 20 of the scope 2 is generated as an image signal; the monitor 8 as a display device outputs the image signal generated by the above-mentioned image processing device 5, and displays the endoscopic image. ; the operation part 9, which is electrically connected with the above-mentioned control unit 3; Disassemble.

[0050] The above-mentioned endoscope 2...

Embodiment 2

[0207] Figure 23 to Figure 27 It relates to Embodiment 2 of the electric bending endoscope device of the present invention. FIG. 23 is a block diagram showing the configuration of a control unit provided in the operation unit. FIG. 24 is a block diagram showing a specific configuration of the bending instruction unit signal processing unit in FIG. 23 . Figure 25 It is an explanatory diagram for setting an angle pattern described later of the operation unit by a determination process based on information of the identification ID in FIG. 23 . Figure 26 It is an electric signal coordinate diagram of the bending instruction part instruction signal after the signal processing in the game mode mentioned later. Figure 27 It is the electrical signal coordinate diagram of the indication signal of the bending indication part after the signal processing in the angle knob mode. In addition, in FIG. 23 and FIG. 24, the same reference numerals are assigned to the same constituent ele...

Embodiment 3

[0224] 28 and 29 relate to Embodiment 3 of the electric bending endoscope device of the present invention. FIG. 28 is a block diagram showing the configuration of a control unit provided in the operation unit. FIG. 29 is a block diagram showing a specific configuration of the bending instruction unit signal processing unit in FIG. 28 . In addition, FIG. 28 and FIG. 29 assign the same reference numerals to the same constituent elements as those of the above-mentioned embodiment 2 and omit description, and only the different parts will be described.

[0225] In this embodiment, as shown in FIG. 28 , a reference voltage signal (also referred to as a Ref reference voltage signal) as a reference from the bending instruction unit 9A is input to the bending instruction unit signal processing unit 31 .

[0226] That is, as shown in FIG. 29 , the above-mentioned Ref reference voltage signal is input to the A / D conversion circuit 41 of the bending instruction unit signal processing uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com