6000 aluminum extrudate excelling material of good paint-baking hardenability and process for producing the same

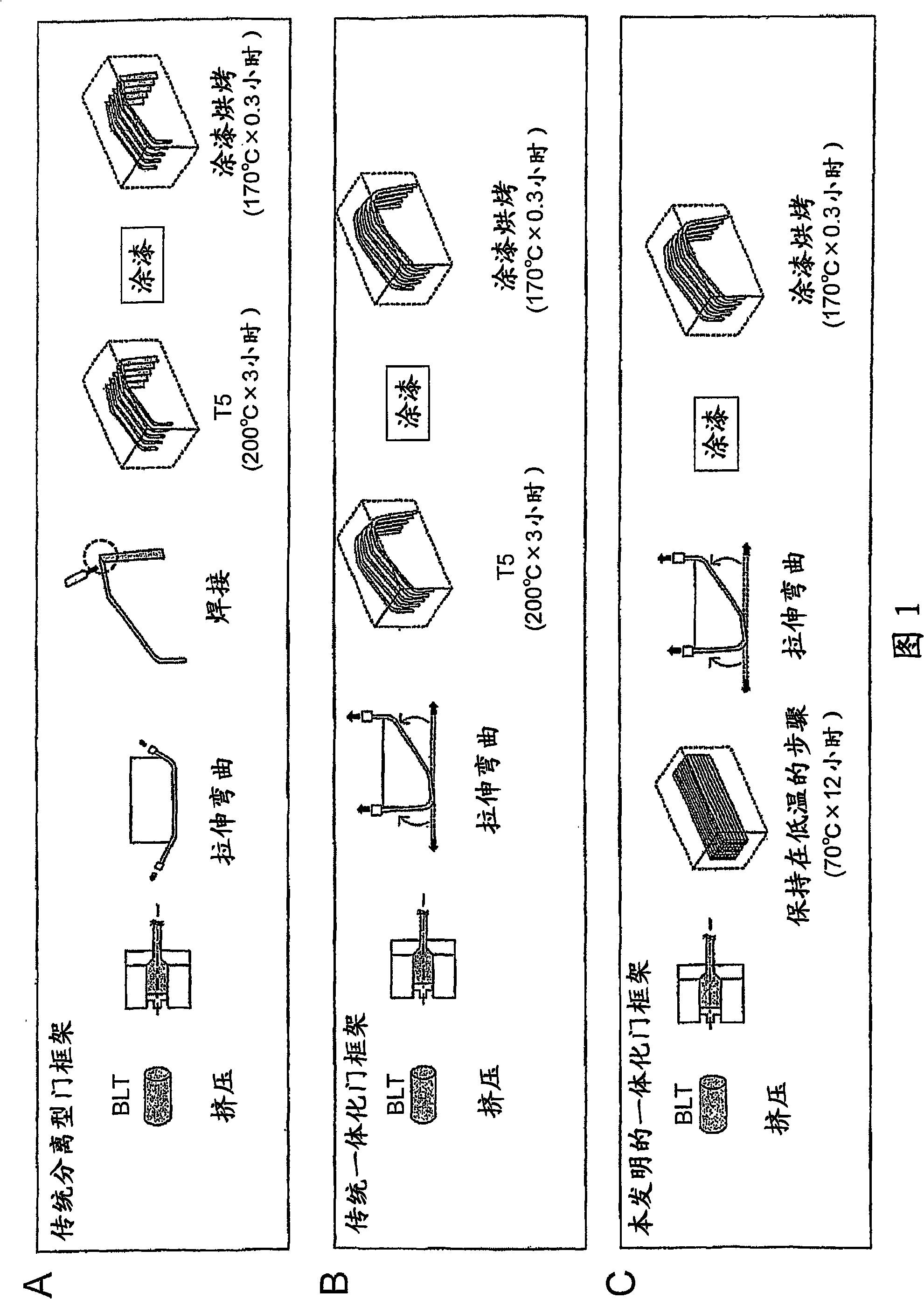

An aluminum extrusion and extrusion molding technology, applied in the field of 6000 series aluminum extrusion materials, can solve the problems of increasing yield strength and decreasing yield strength, and achieve the effect of sufficient yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Examples and comparative examples of the present invention are described below.

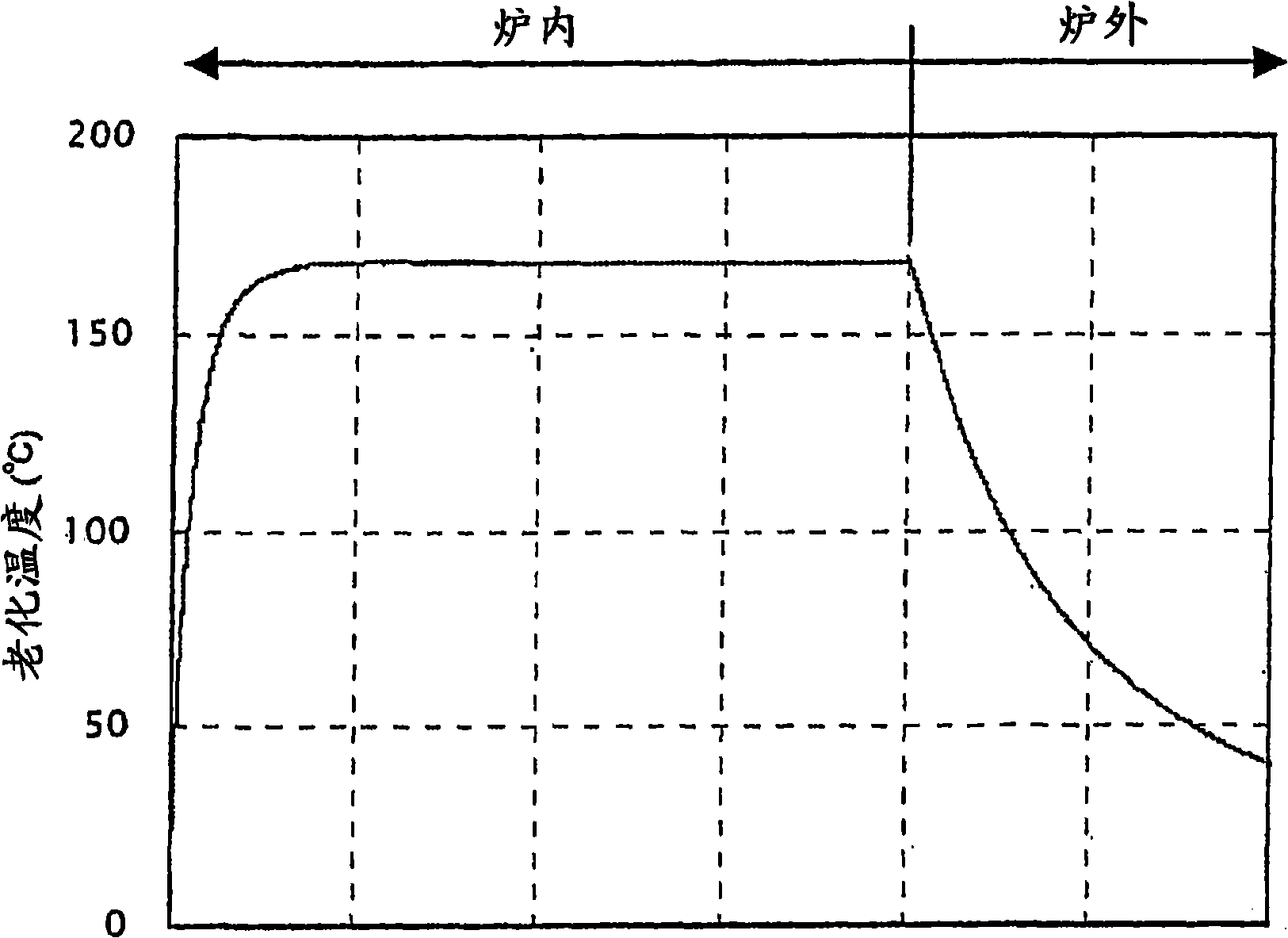

[0057][Manufacturing method: (1) Hold at 90±50°C×1 to 24 hours immediately after extrusion molding]

[0058] First, the raw material content was adjusted to achieve the composition of the 6000-series aluminum alloy as shown in Sample Nos. 1 and 2 listed in Table 1. The raw materials were dissolved and melted into cylindrical ingots (diameter: 204 mm x length: 700 mm) with dimensions suitable for extrusion. In addition, the alloy contents listed in Table 1 are expressed as analytical values. Significant digits are expressed as the value "0.00%". Then, the ingot was homogenized at 560° C. for 4 hours.

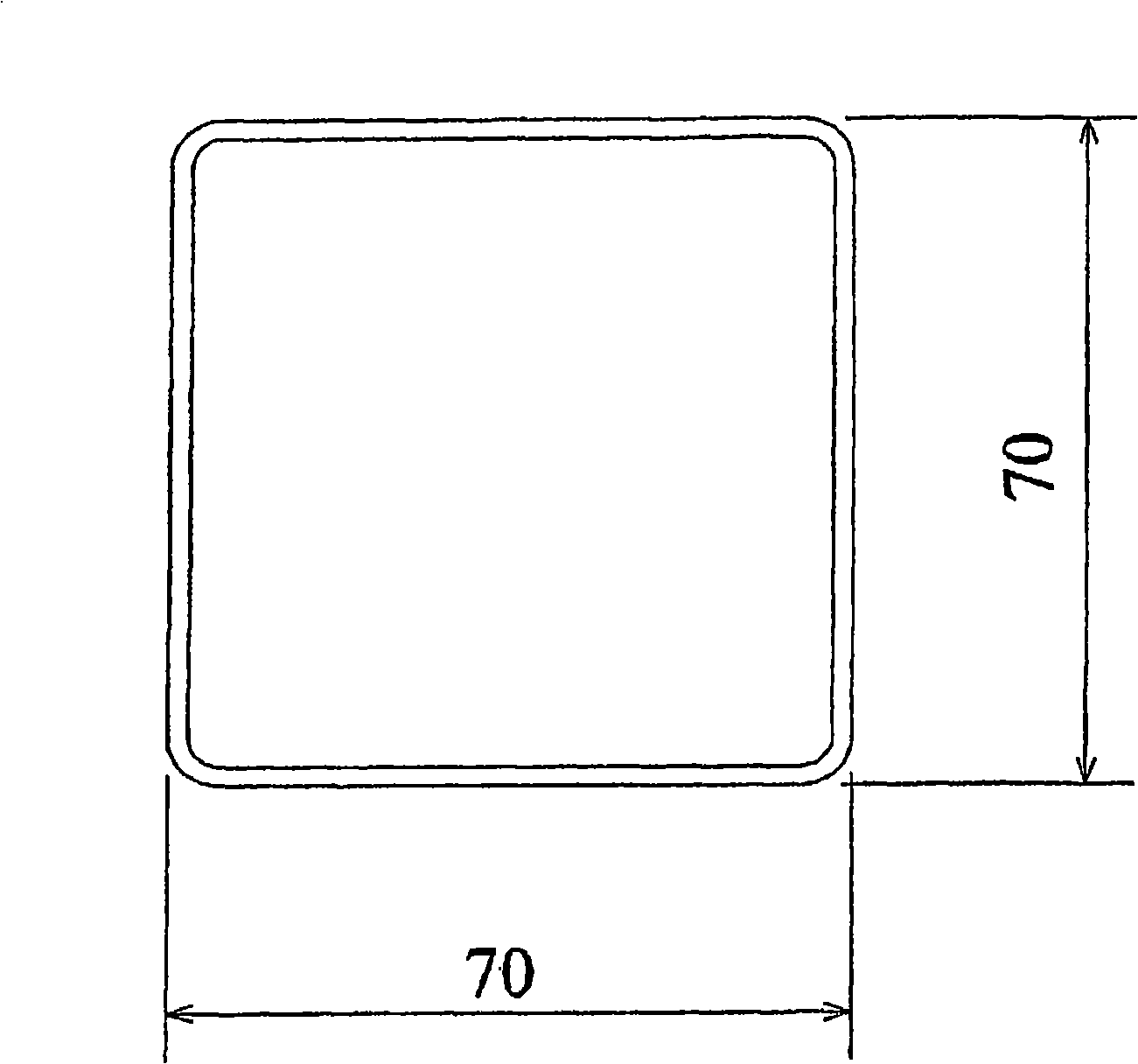

[0059] Next, the homogenized ingot (billet) was extrusion-molded using an extrusion die at a predetermined extrusion temperature (billet heating temperature) under the cooling conditions listed in Table 2. As a result, each has figure 2 Extruded aluminum profiles for frame member cross-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com