Feed additive for feeding boar without boar taint and boar meat using the same

A feed additive, boar technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of lower feed utilization rate, lower productivity, higher fat content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] In the preparation of feed additives it is preferred to include all Fe in metal cations 2+ , Mg 2+ , Mn 2+ and Ca 2+ , and more preferably include the same weight ratio of Fe 2+ , Mg 2+ , Mn 2+ , Ca 2+ 、Co 2+ 、K + 、Cu 2+ , Zn 2+ 、Mo 2+ and Na + .

[0029] The feed additive prepared by the above method can be supplied to boars in an amount of 0.005-0.05% by weight relative to the total amount of the feed composition, more preferably, in an amount of 0.01% by weight. In addition, the present invention provides pork produced from boars fed with the feed additive of the present invention.

Embodiment 1

[0031] Embodiment 1: the preparation of feed additive

[0032] Mix 10 kg each of brown seaweed, fucus, sargassum and crab shells, and acid hydrolyze the mixture with 20 kg of 5N HCl, then neutralize with 5N NaOH to pH 7.0, and mature at 35°C for 1 month, then Filter (with a Milipore Co. filter) to remove solids.

[0033] Fe, Mg, Mn, Cu, Zn and Mo were all dissolved in 5N HCl and passed through a cation exchange membrane to prepare Fe 2+ , Mg 2+ , Mn 2+ 、Cu 2+ , Zn 2+ and Mo 2+ cationic water (solution).

[0034] CaCO 3 dissolved in 5N HCl and passed through a cation exchange membrane to produce Ca 2+ cationic water (solution).

[0035] Will Co(NO 3 ) 2 , KCl and NaCl are dissolved in water and pass through a cation exchange membrane to produce Co 2+ 、K + and Na + cationic water (solution).

[0036] 25 parts by weight of Fe containing 0.1% by weight 2+ , Mg 2+ , Mn 2+ , Ca 2+ 、Co 2+ 、K + 、Gu 2+ , Zn 2+ 、Mo 2+ and Na + Cationic water (which is arranged i...

experiment example 1

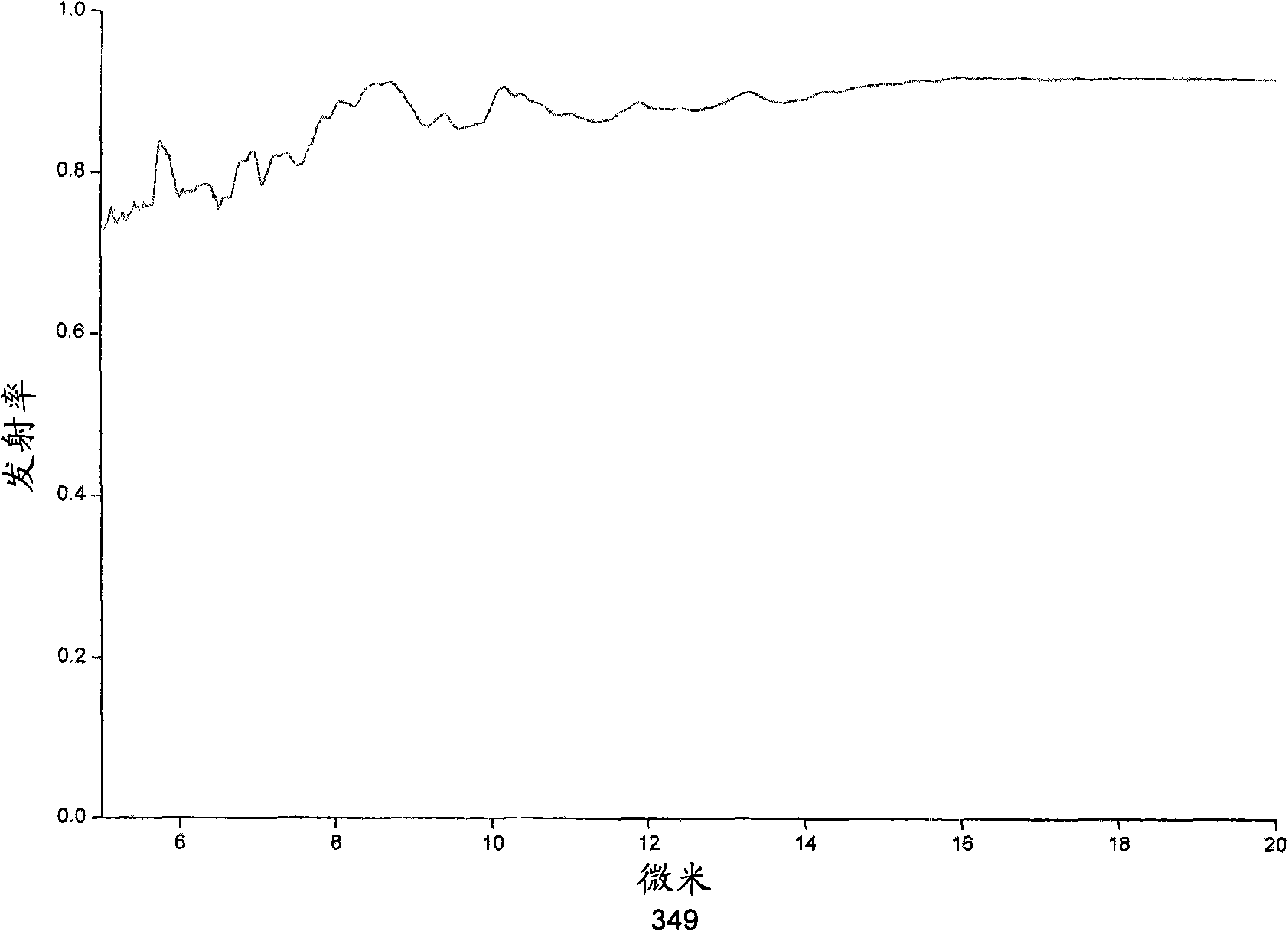

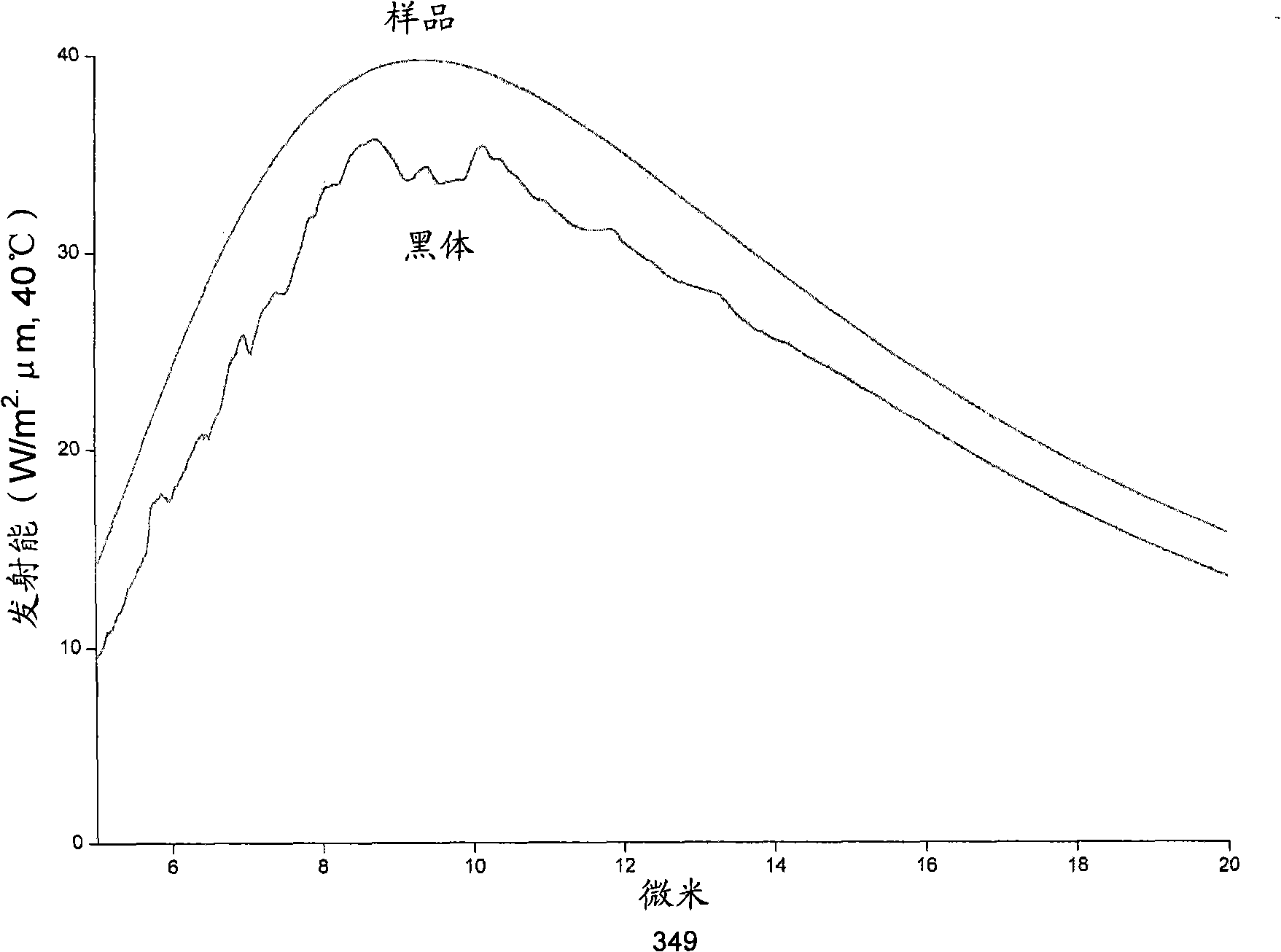

[0037] Experimental Example 1: Radiation Experiment

[0038] The feed additive of the present invention obtained in Example 1 requires radiation experiments at the Far Infrared Application Evaluation Center of KICM (Korea Institute of Construction Materials).

[0039] In the radiation experiment results of the Korea Building Materials Research Institute (Far Infrared Application Evaluation Center), the results in Table 1 below can be confirmed. The following results are obtained at 40° C., and are measurement results using an FT-IR spectrometer compared with black body (BLACK BODY). in addition, figure 1 and figure 2 A graph showing the emissivity and emissivity of the feed additive of the present invention.

[0040] Table 1: Results of radiation experiments on feed additives

[0041] Emissive (5-20μl)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com