Processing method for preparing polymer solution by oil production sewerage

A technology of polymer solution and oil production sewage, applied in the direction of heating water/sewage treatment, etc., can solve the problems of small processing capacity, high requirements, complex equipment maintenance, etc., and achieve the effect of less maintenance workload, long service life and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

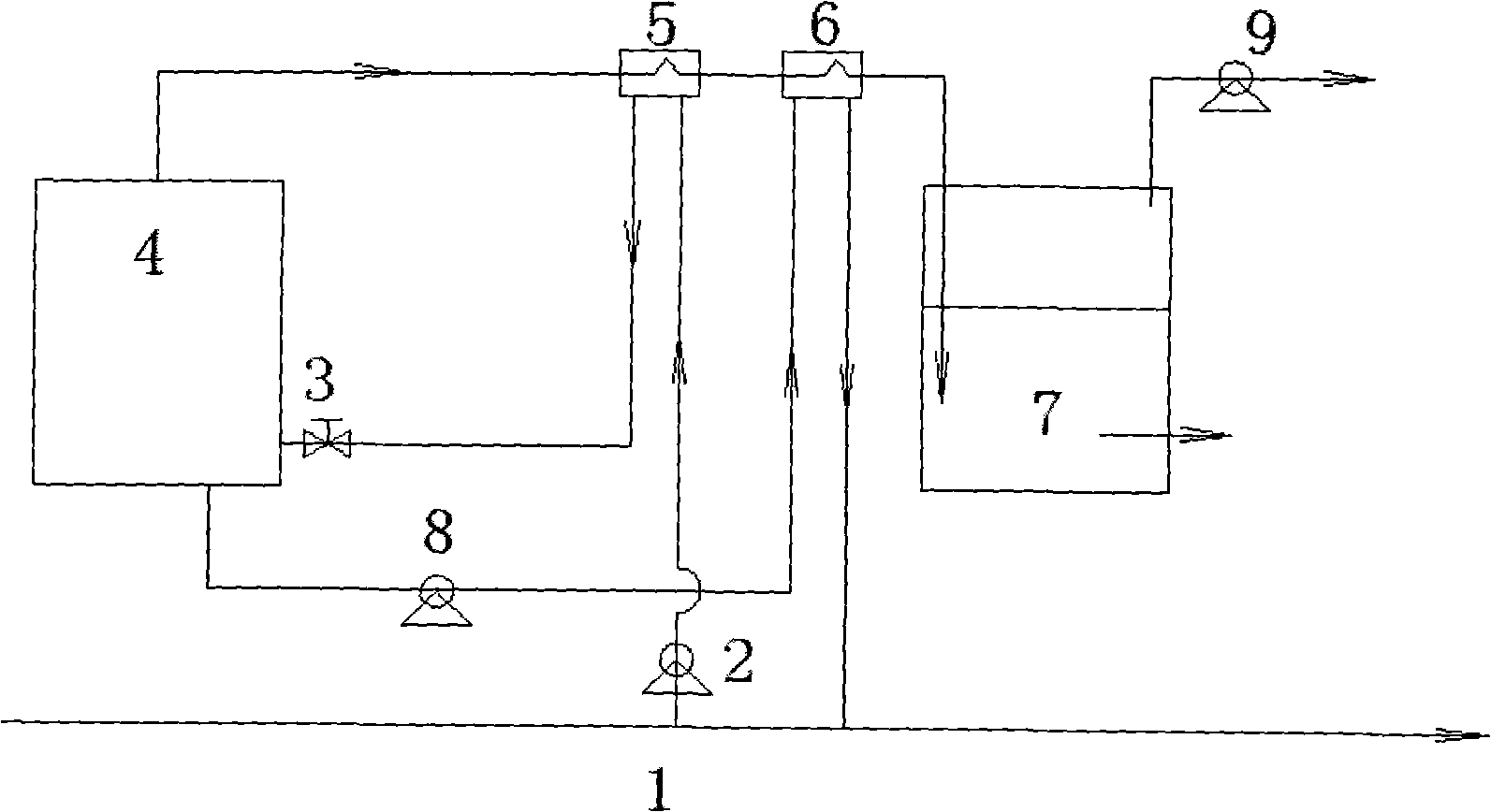

[0015] combined with figure 1 , the present invention is further described, and the technical scheme is: the oil production sewage that reaches the oilfield sewage reinjection standard through the treatment of the sewage treatment station of the oilfield gathering and transportation system 1. (see figure 1 ) is pressurized to the pressure P1 (0.6-0.8MPa) by the water pump ②, and the temperature is further increased by the heat exchanger ⑤, and then the oil production sewage enters the evaporation equipment ④ from the steam trap ③, and the pressure is rapidly reduced to P2 (P1>10P2) P2 (0.06-0.08 MPa), the sewage will be quickly evaporated into steam, and the steam will be cooled by the condenser ⑥ to be purified water ⑦ (that is, the product water obtained through the treatment of the present invention), and the whole system is driven by a vacuum pump ⑨ to a negative pressure state. The unevaporated oil production sewage is lifted by the water pump ⑧ and enters the condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com