Method for measuring carboxymethylcellulose enzyme activity

A technology of carboxymethyl cellulose and sodium carboxymethyl cellulose, which is applied in the field of determination of carboxymethyl cellulose enzyme activity, can solve problems such as errors, and achieve the effects of small errors, good reproducibility, and fast test speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

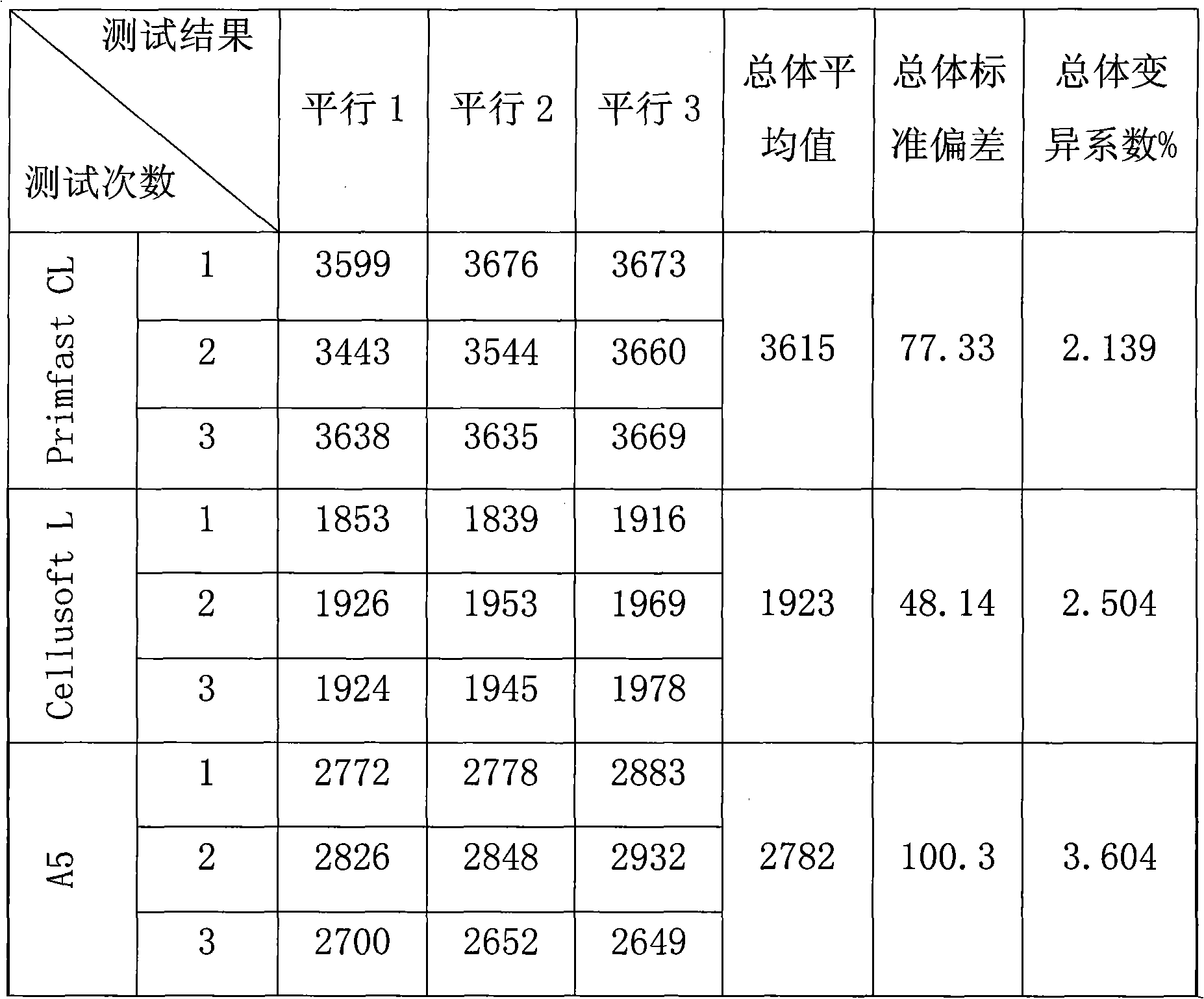

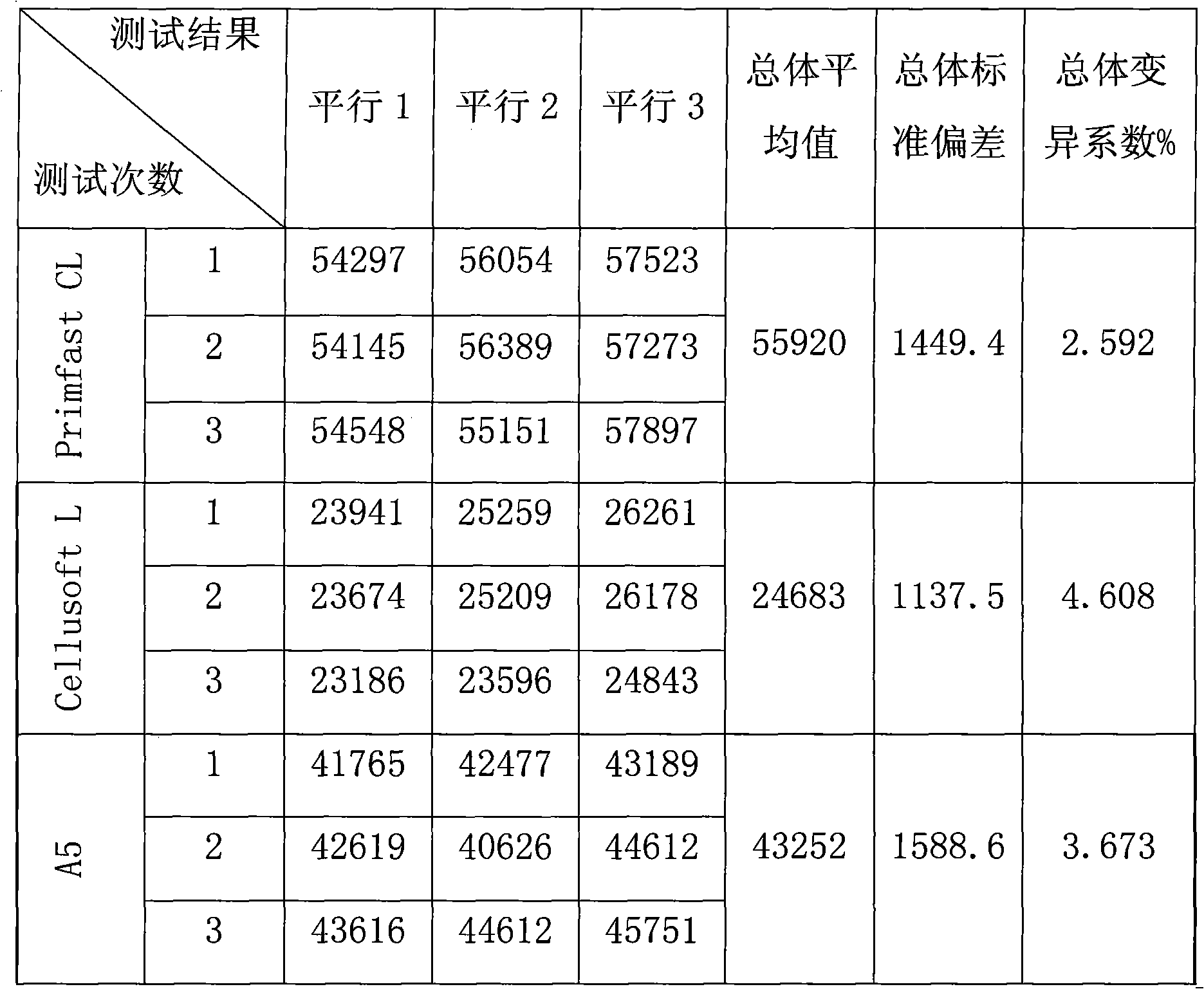

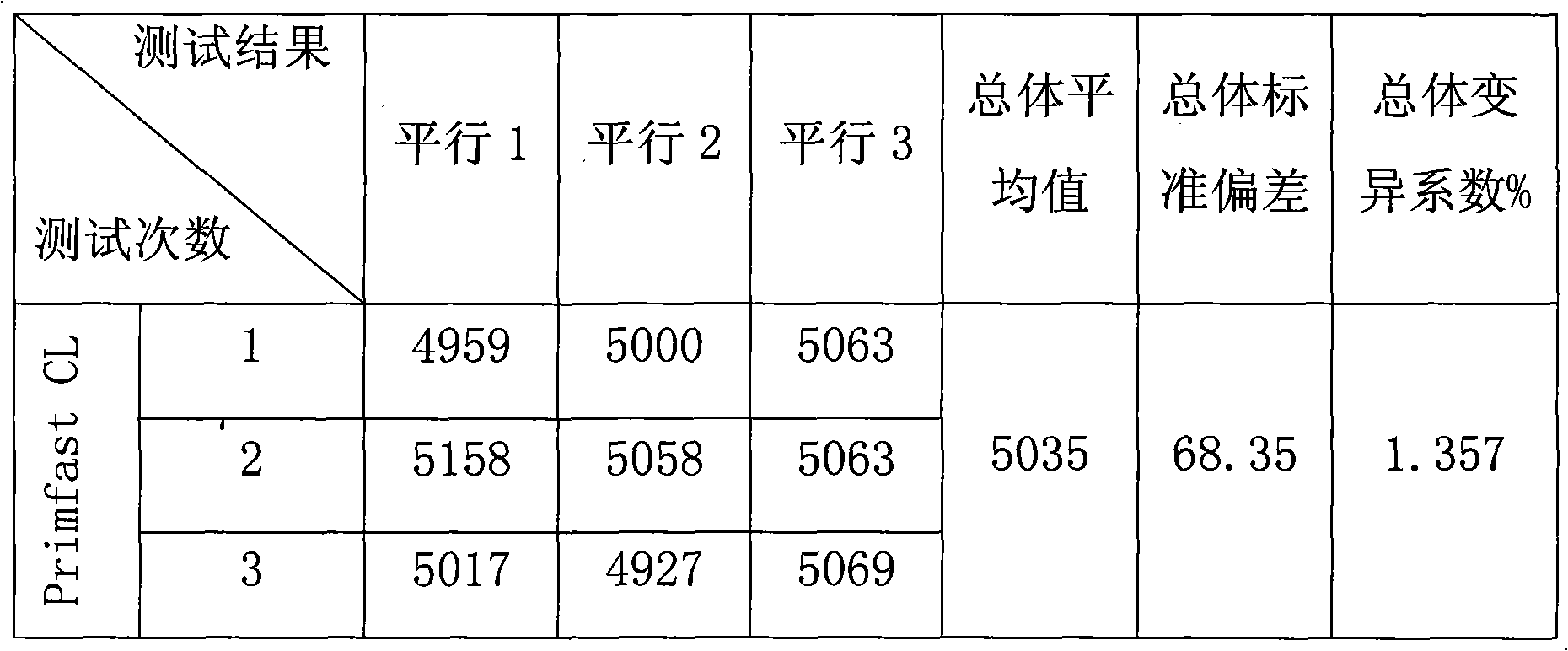

example 1

[0031] Add 200μL of the enzyme solution to be tested diluted to an appropriate multiple into a 2mL disposable plastic centrifuge tube, then add 1% sodium carboxymethylcellulose (Sigma, low viscosity) solution substrate equal in volume to the enzyme solution, and mix well. Place the reaction at 50℃ for 10 minutes; at the same time as a blank control of the enzyme, add 200μL of the enzyme solution to be tested diluted to an appropriate multiple into the reaction tube, and then add 3 times the volume of the enzyme solution DNS (3,5-dinitrosalicylic acid) Reagents, mix well, and react at 50℃ for 10 minutes; take out all reaction tubes, immediately add 3 times the volume of enzyme solution DNS (3,5-dinitrosalicylic acid) reagent to the sample tube, mix well, and add the enzyme to the control tube Liquid equal volume of 1% sodium carboxymethylcellulose (Sigma, low viscosity 4%) solution substrate, mix well; put all reaction tubes in a boiling water bath and heat for 5 minutes, take them...

example 2

[0037] Add 100μL of the enzyme solution to be tested diluted to an appropriate multiple into a 2mL disposable plastic centrifuge tube, then add 1% sodium carboxymethylcellulose (Sigma, low viscosity) solution substrate equal in volume to the enzyme solution, and mix well. Place the reaction at 50℃ for 10 minutes; at the same time as a blank control of the enzyme, add 100μL of the enzyme solution to be tested diluted to an appropriate multiple into the reaction tube, and then add 3 times the volume of the enzyme solution DNS (3,5-dinitrosalicylic acid) Reagents, mix well, and react at 50℃ for 10 minutes; take out all reaction tubes, immediately add 3 times the volume of enzyme solution DNS (3,5-dinitrosalicylic acid) reagent to the sample tube, mix well, and add the enzyme to the control tube Liquid equal volume of 1% sodium carboxymethylcellulose (Sigma, low viscosity) solution substrate, mix well; put all reaction tubes in a boiling water bath and heat for 5 minutes, take them ou...

example 3

[0042] Add 300μL of the enzyme solution to be tested diluted to an appropriate multiple into a 2mL disposable plastic centrifuge tube, then add 1% sodium carboxymethylcellulose (Sigma, low viscosity) solution substrate equal in volume to the enzyme solution, and mix well. Put it at 50℃ for 10min; at the same time as a blank control of the enzyme, add 300μL of the enzyme solution to be tested diluted to an appropriate multiple into the reaction tube, and then add 3 times the volume of the enzyme solution DNS (3,5-dinitrosalicylic acid) Reagents, mix well, and react at 50℃ for 10min; take out all reaction tubes, immediately add 3 times the volume of enzyme solution DNS (3,5-dinitrosalicylic acid) reagent to the sample tube, mix well, and add the enzyme to the control tube Liquid equal volume of 1% sodium carboxymethylcellulose (Sigma, low viscosity) solution substrate, mix well; put all reaction tubes in a boiling water bath and heat for 5 minutes, take them out, and quickly cool to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com