Apparatus for improving electrical arc ion plating deposition film quality

A technology of arc ion plating and thin film, which is applied in the direction of ion implantation plating, sputtering plating, vacuum evaporation plating, etc. It can solve the problems affecting the performance and life of coatings and films, and achieve the reduction of the content of large particles, regulation Effects with a large range and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

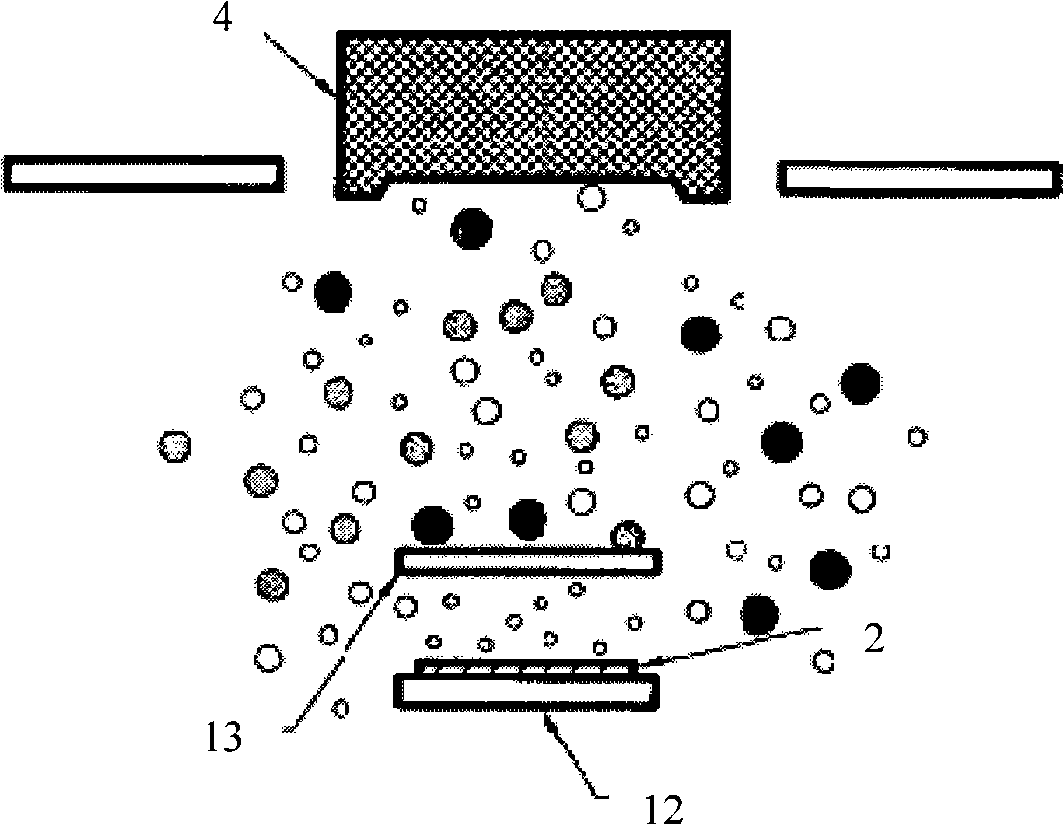

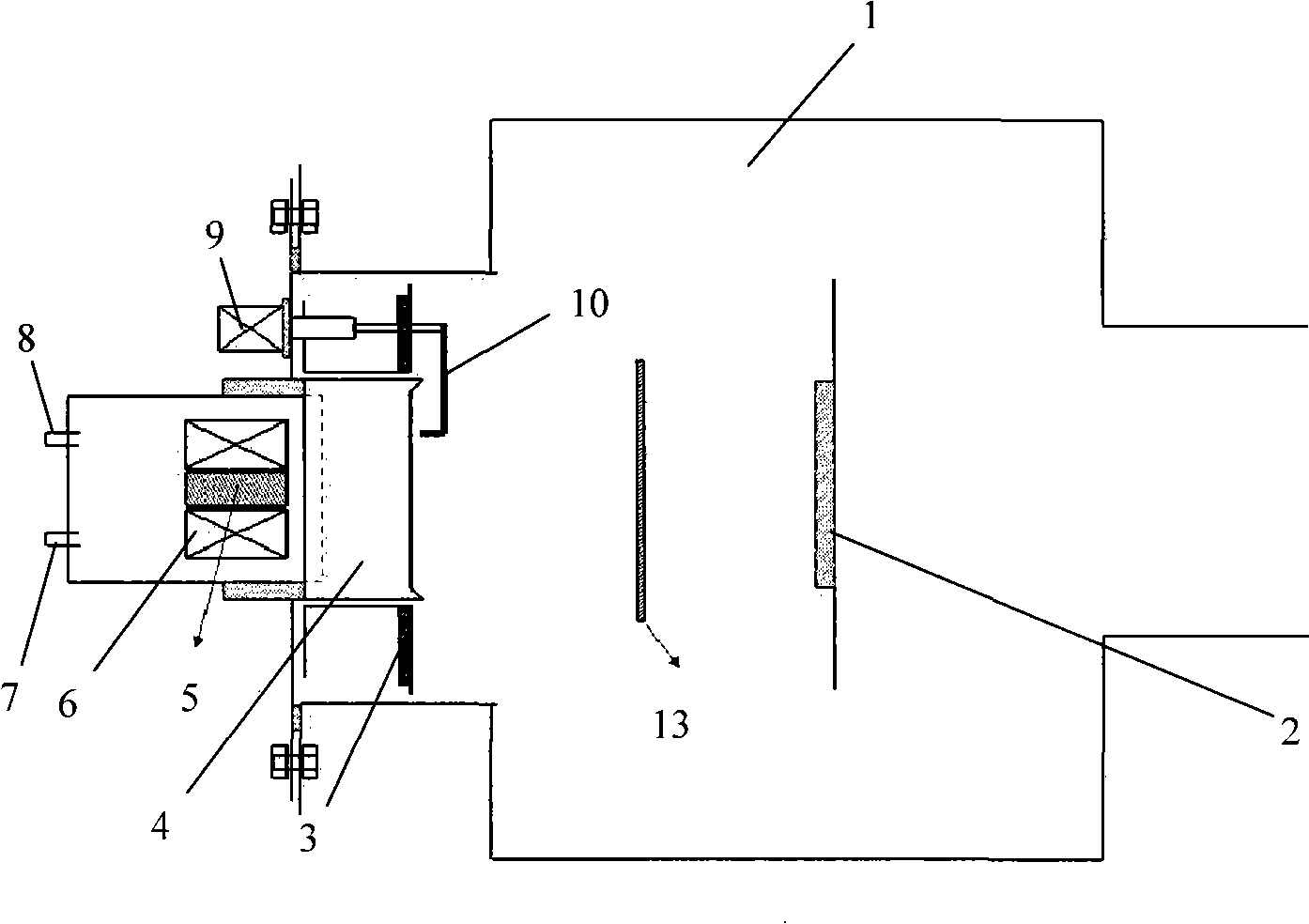

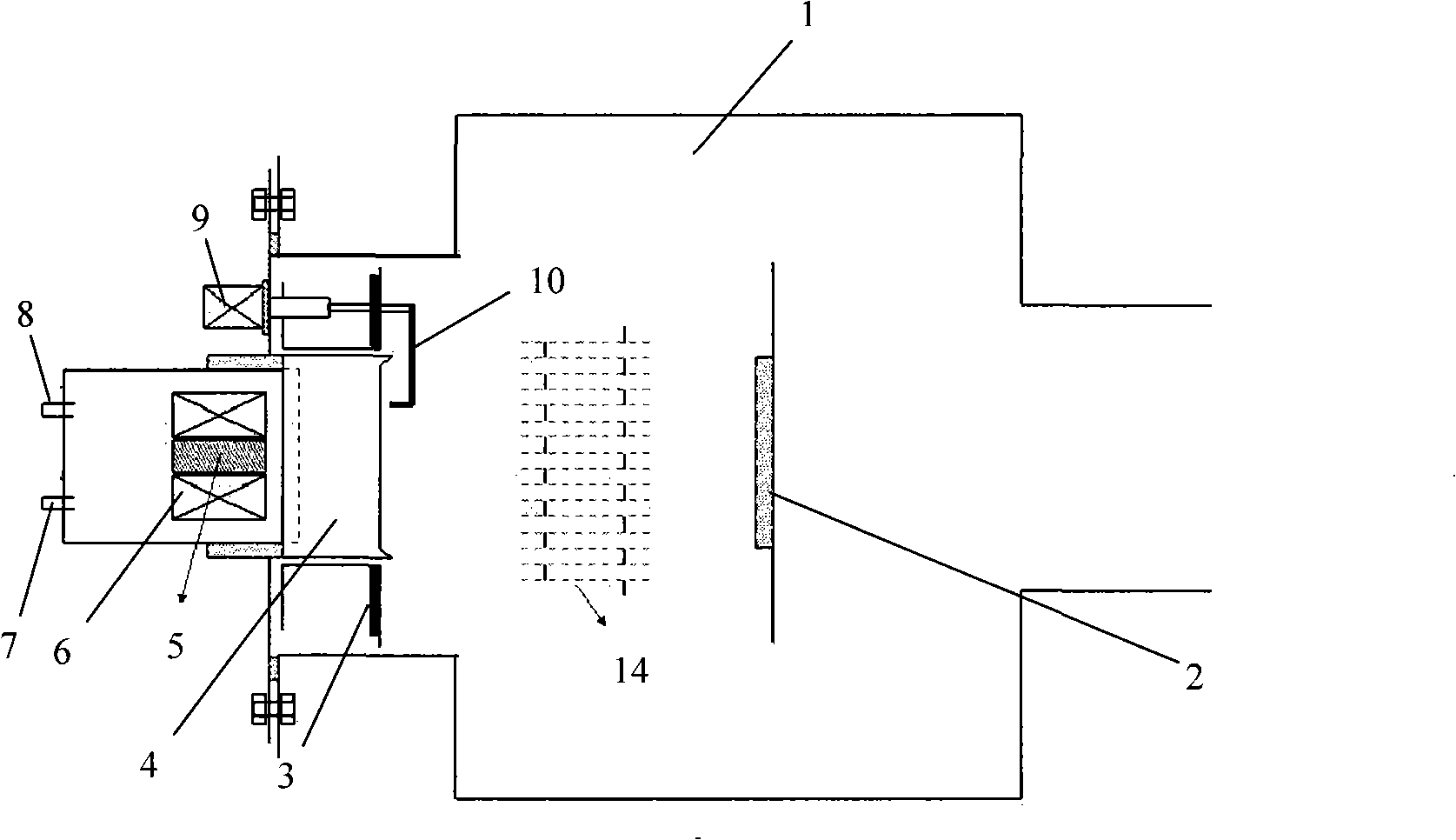

[0053] attached image 3 It is the embodiment device figure of scheme one of the present invention, and figure 2 The difference is that the double-layer perforated baffles 14 (perforated baffles I15, perforated baffles II16) are placed between the cathode target 4 and the substrate 2, and the distance between the target 4 and the substrate 2 is equal. The structure of double-layer perforated baffle plate 14 is as Figure 4 As shown, the perforated baffle I15 and the perforated baffle II16 in the double-layer perforated baffle 14 are coaxially placed in parallel, and are also placed coaxially with the target 4 and the substrate 2. The perforated baffle I15 and the perforated baffle The distance between II16 is 50mm. In this embodiment, the baffle plate I15 with holes and the baffle plate II16 with holes are made of stainless steel sheet, the shape of the baffle plates is a regular hexagon, and the length between opposite sides is 100mm. The shape of the hole is circular, th...

Embodiment 2

[0056] attached Figure 8 It is an embodiment device diagram of the second scheme of the present invention. On the basis of Embodiment 1, an enhanced magnetic field coil 11 is added to the substrate, and the enhanced magnetic field coil 11 is placed coaxially with the target material 4 and the double-layer perforated baffle plate 14. The distance between the enhanced magnetic field coil 11 and the substrate 2 can be adjusted. The enhanced magnetic field coil 11 is circular in shape, with an inner diameter of 100mm, an outer diameter of 180mm, and a thickness of 50mm. The electromagnetic coil is wound with QZY-2 high-temperature enameled wire, and the coil is wrapped with high-temperature-resistant glass cloth to ensure high-temperature insulation. The coil leads use high temperature wires and are covered with porcelain tubes for protection. The coil current is regulated by a DC voltage regulator, and adjusting the magnitude of the current can change the strength of the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com