Outer bucket cover with spray function and washing machine using thereof

A technology for an outer tub cover and a washing machine, applied in the field of washing machines, can solve the problems of large cover area, high cost, unstable water flow, etc., to overcome three defects and deficiencies, easy centrifugal washing and foam washing, and improve the strength of blowing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

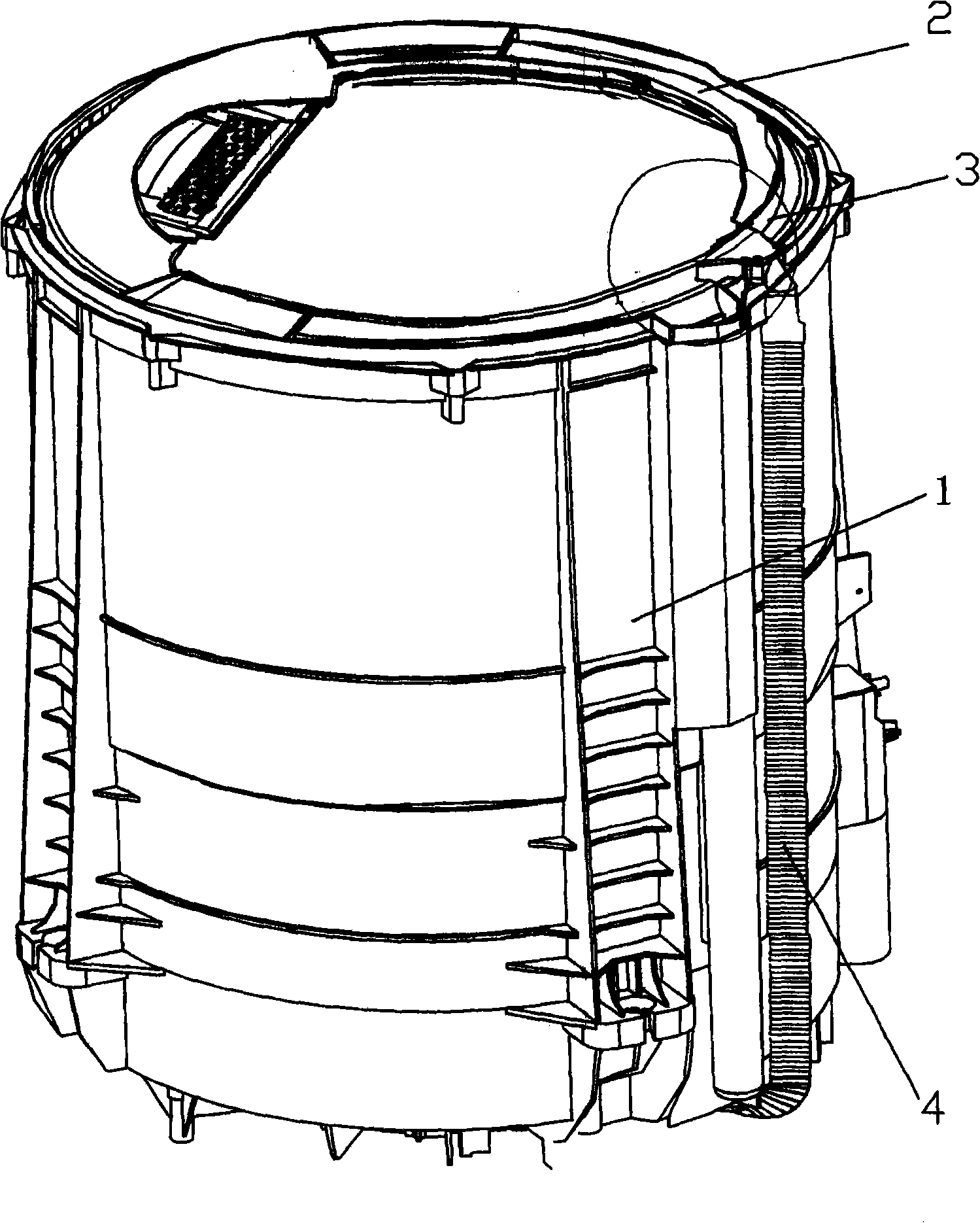

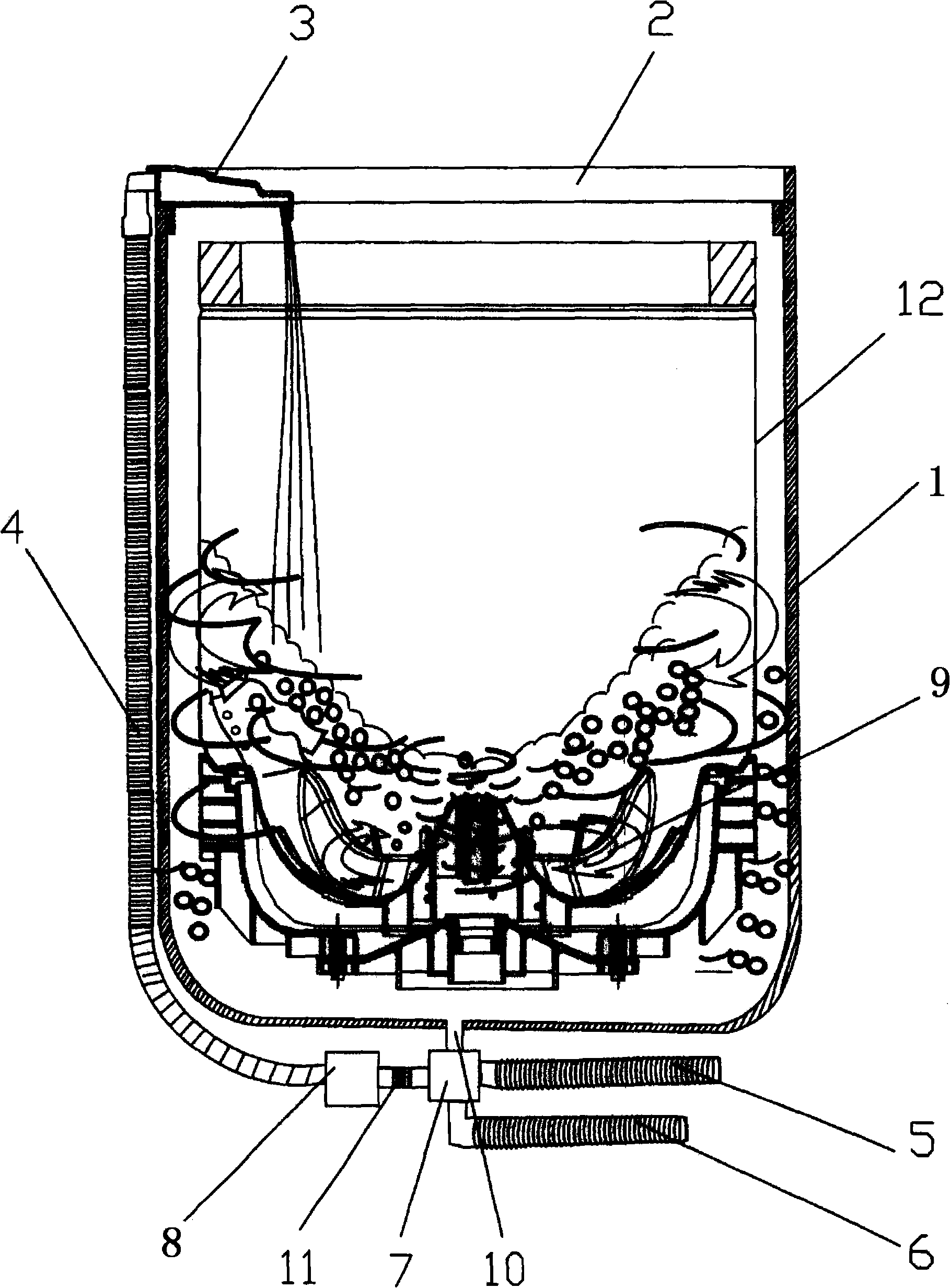

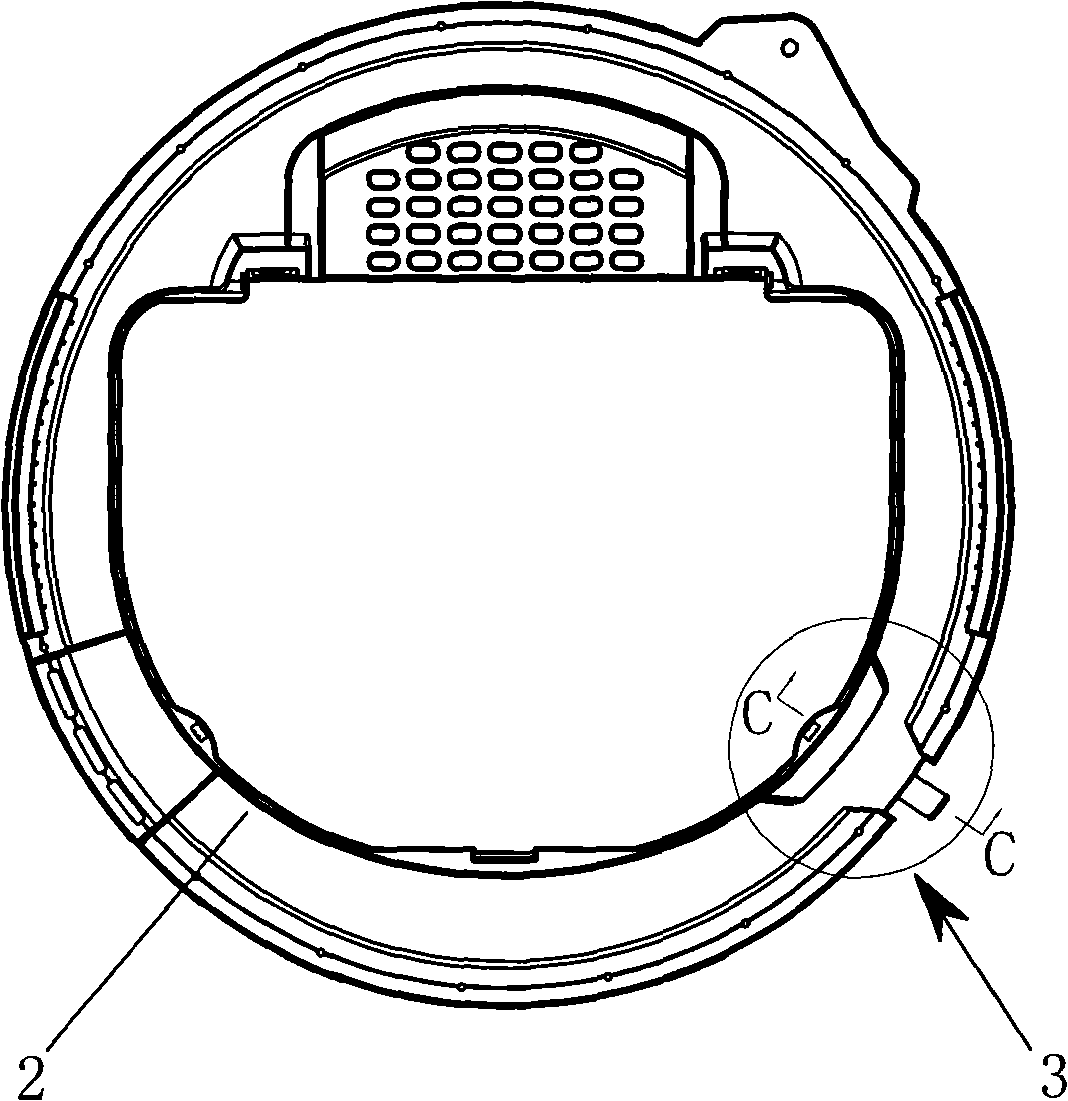

[0032] Such as Figure 1 to Figure 5 As shown, the washing machine of the present invention includes: a washing inner tub 12 for accommodating laundry, a washing outer tub 1 for storing washing water in the washing inner tub, a driving device and a drainage device are arranged at the bottom of the washing outer tub 1, and the drainage device includes: Water pipe 5, drain pipe 6, drain valve device 7, communication pipe 10, upper drain pipe 11, a communication pipe 10 is provided at the bottom of the washing tub 1, the output end of the communication pipe 10 is connected with the drain valve device 7, and the drainage The valve device 7 is respectively connected with the overflow pipe 5, the drain pipe 6, and the upper drain pipe 11, the output end of the upper drain pipe 11 is connected with the water pump 8, the output end of the water pump 8 is connected with the input end of the circulation pipe 4, and the circulation pipe The output end of 4 is connected with the spray dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com