Rotation position control method and apparatus for switching reluctance motor

A technology of switched reluctance motor and rotation position, which is applied in the direction of single motor speed/torque control, control using feedback, electronic commutator, etc. It can solve the problem of stepping motor out of step and stepping motor with weak load capacity , Motor out of step and other problems, to achieve the effect of improving the position control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

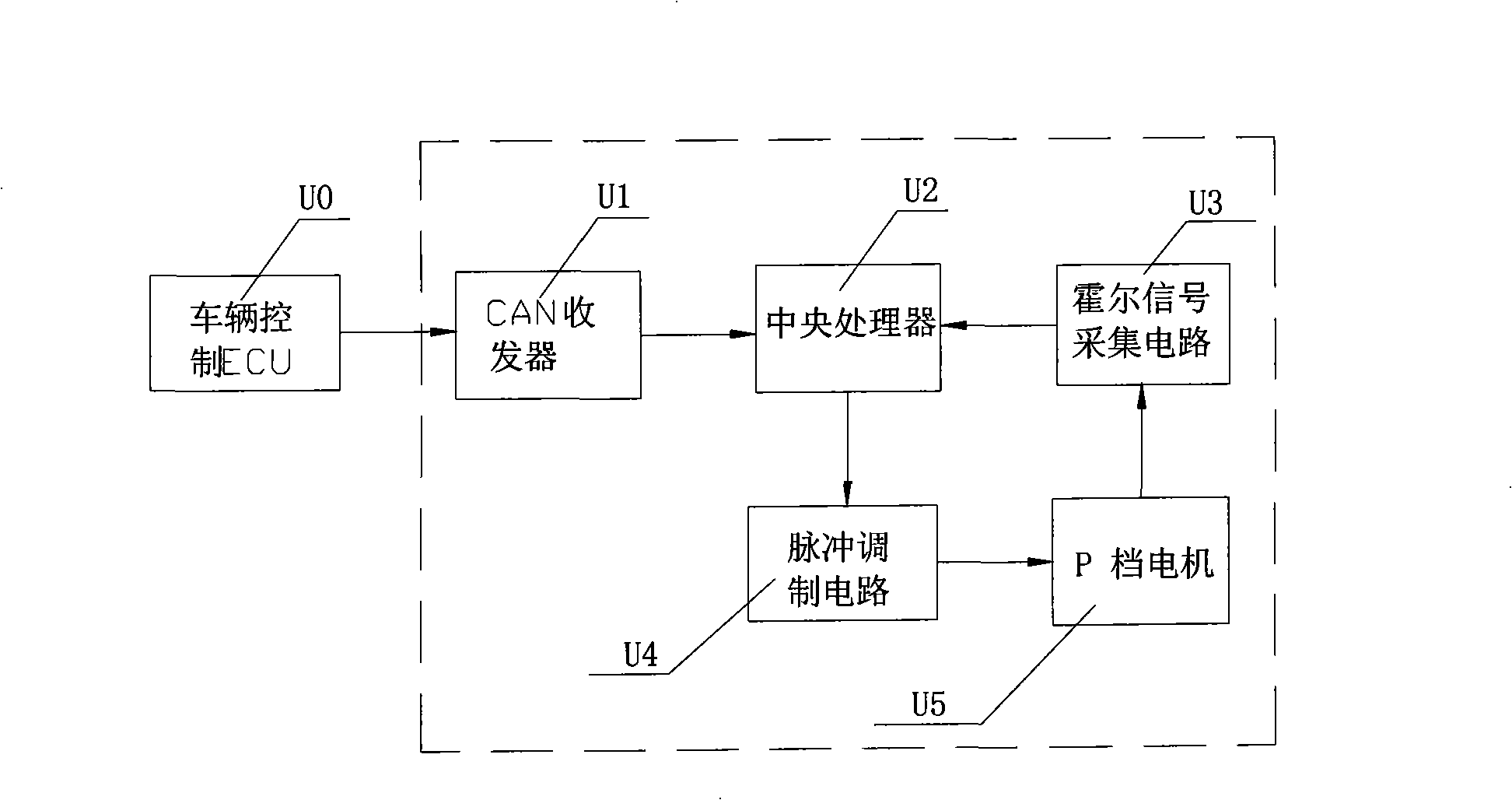

[0035] The traditional switched reluctance motor control uses frequency conversion speed regulation to comprehensively control the motor speed and output power, and its stable working area is in the medium and high speed area (greater than 1000 rpm). In the low-speed area, the traditional switched reluctance motor control method adopts "voltage PWM control", that is, the difference between the speed setting value and the actual speed is used to modulate the DC voltage and add it to the effective time of the conduction phase winding to change the effective time of the external voltage. value, thereby changing the torque.

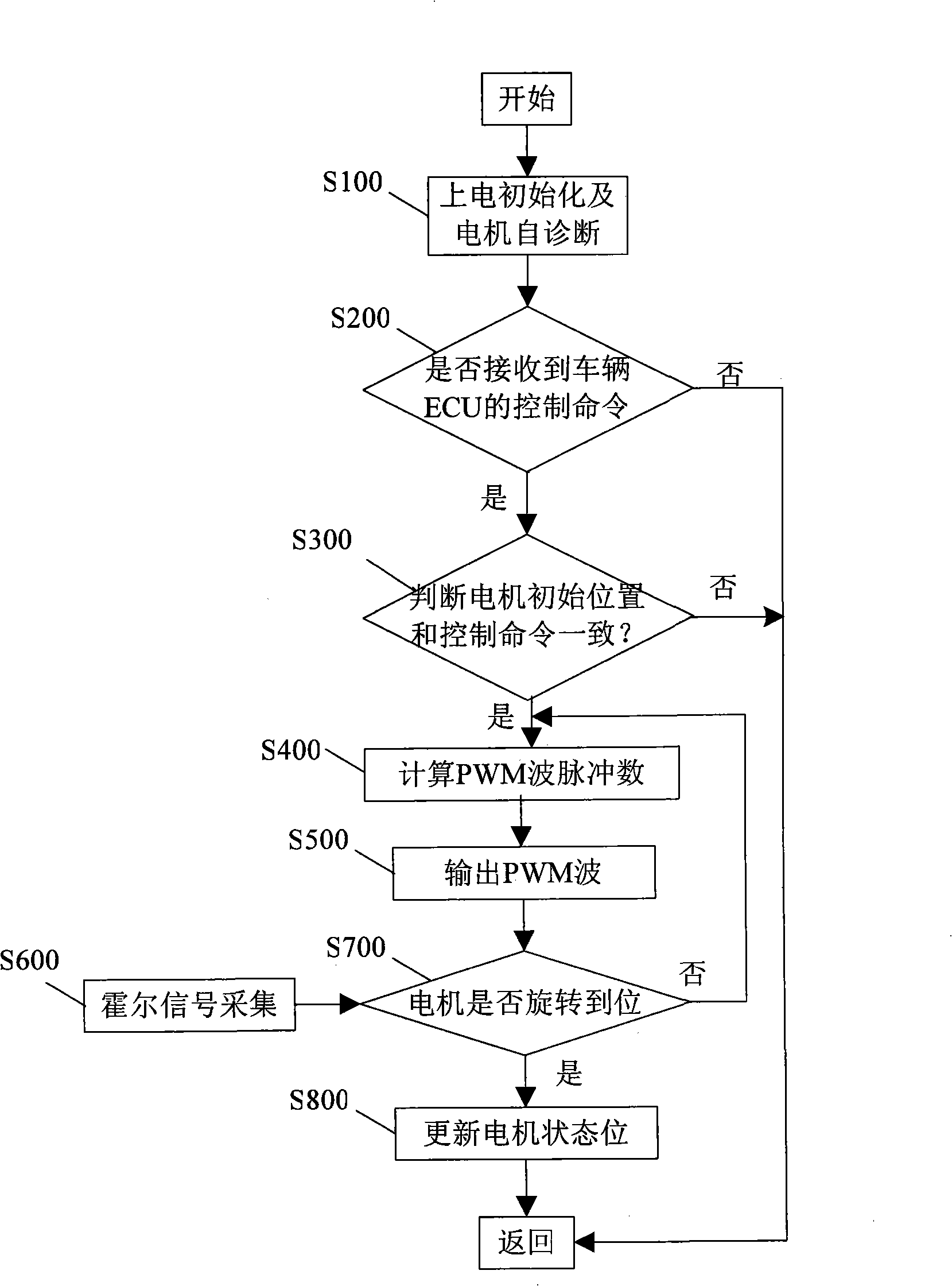

[0036] The control method of the switched reluctance motor in the present invention adopts the method of counting walking pulses, and the features and advantages of the present invention will be described in detail through the embodiments in conjunction with the accompanying drawings.

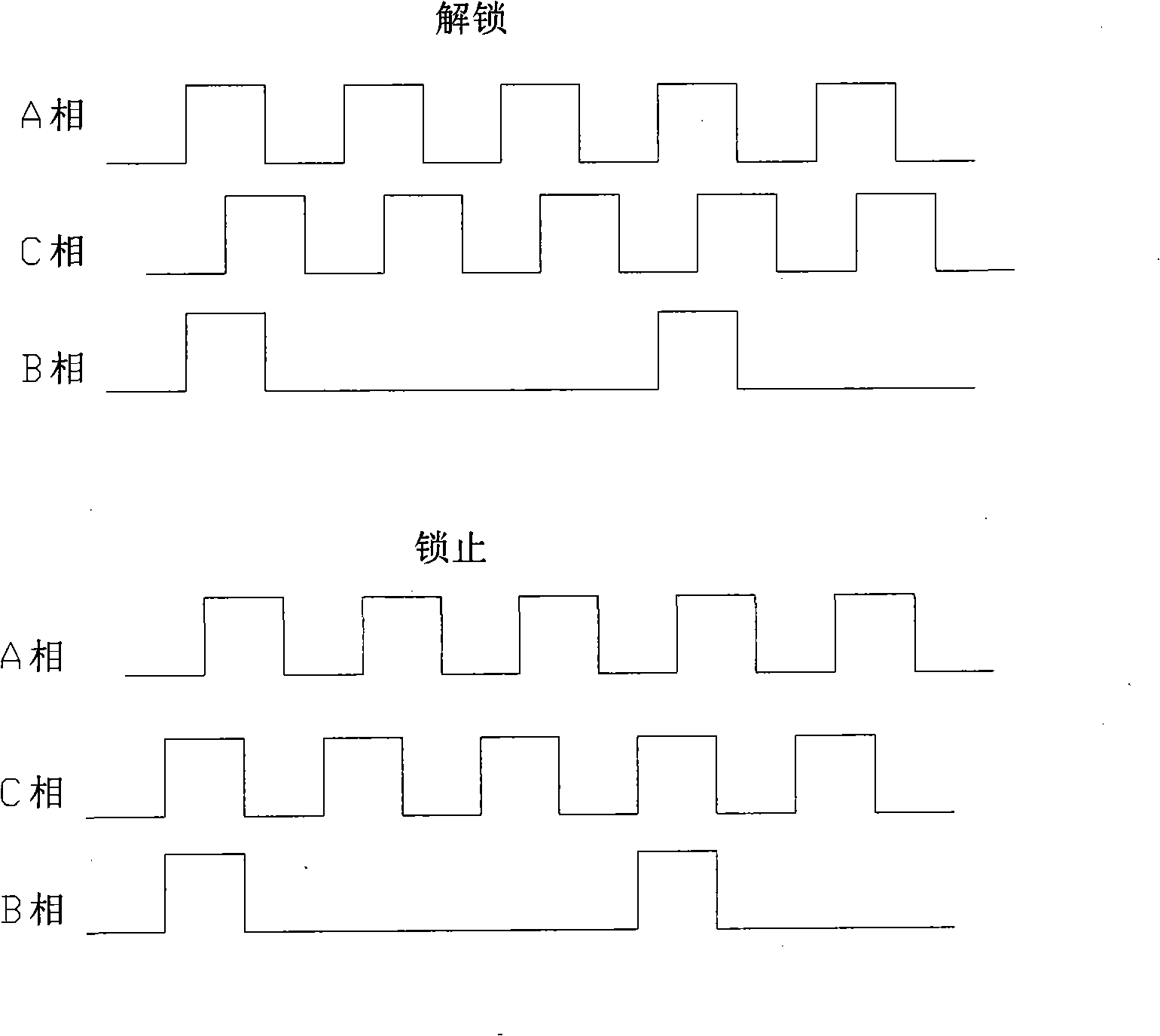

[0037] The locked position of the P gear motor controller refers to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com