Mixed-connected machine tool of parallel cutter head

A machine tool and cutter head technology, applied in the field of hybrid machine tools for five-axis machining, can solve problems such as weak structural rigidity, and achieve the effects of low cost, easy manufacturing, and small space occupied by the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

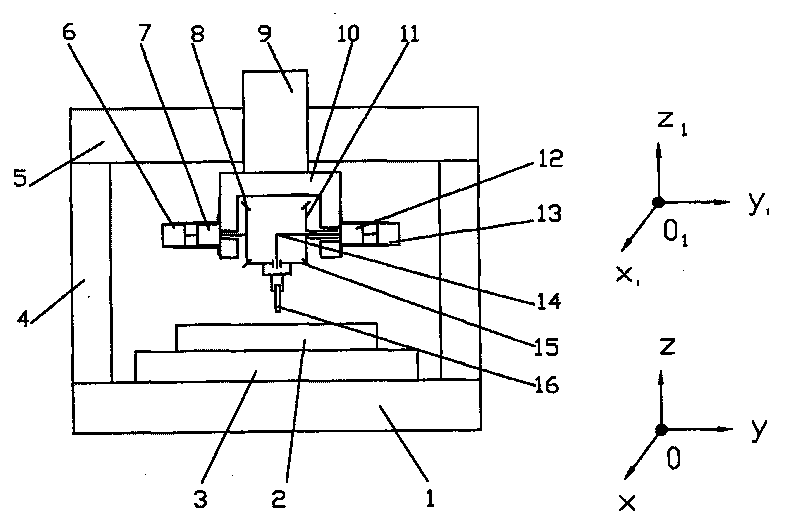

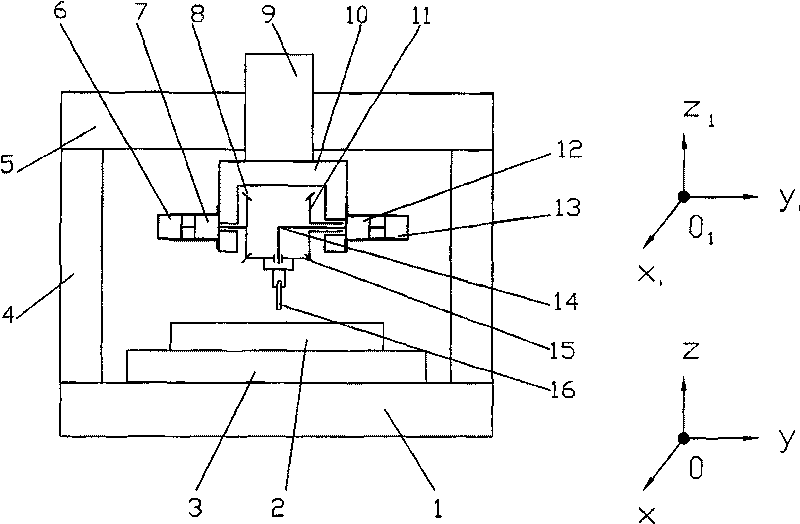

[0012] Such as figure 1 As shown, the horizontal sliding table 3 is installed on the machine base 1, and produces horizontal movement of the X axis; the rotary table 2 is installed on the horizontal sliding table 3, and produces the rotation of the Z axis; the column 4 is installed on the machine base 1; the beam 5 is installed on the column 4; the vertical sliding table 9 is installed on the beam 5, and produces the horizontal movement of the Y axis; the tool holder 10 is installed on the vertical sliding table 9, and produces the vertical movement of the Z axis; the left motor 6, the left deceleration The device 7 is installed on the left side of the tool post 10, and drives the left bevel gear 8 to move; the right motor 13 and the right reducer 12 are installed on the right side of the tool post 10, and drives the tie rod 14 to swing around the Y axis; the tie rod 14 is equipped with a planet The gear 15, the planetary gear 15 and the left bevel gear 8 mesh, the cutter 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com