Cooling method and device of bellow forming module

A cooling device and cooling method technology, applied to corrugated products, tubular items, other household appliances, etc., can solve the problems of leakage of cooling liquid, low cooling efficiency, intermittent injection of cooling liquid, etc., and achieve strong vacuum suction, Improved reliability and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

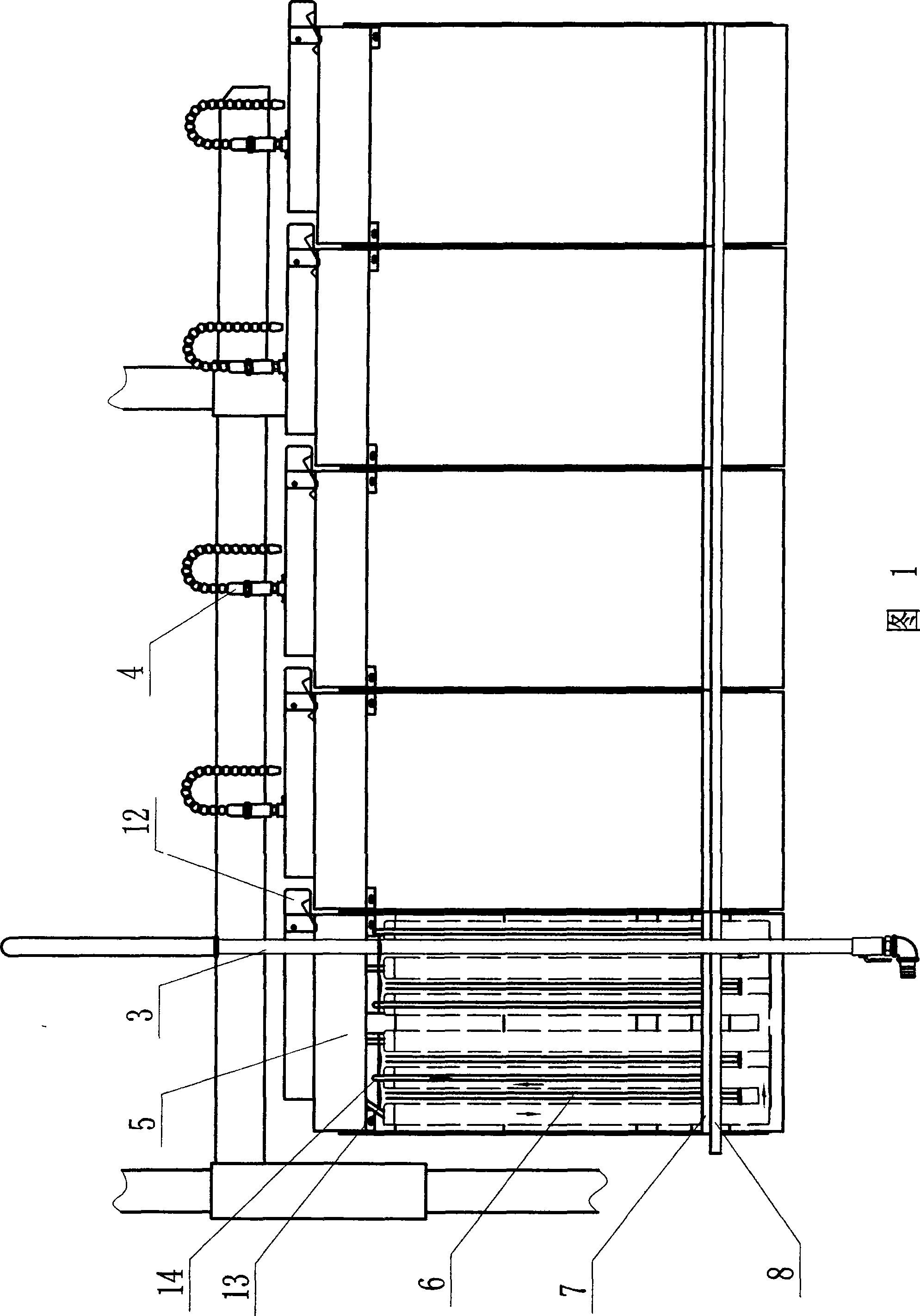

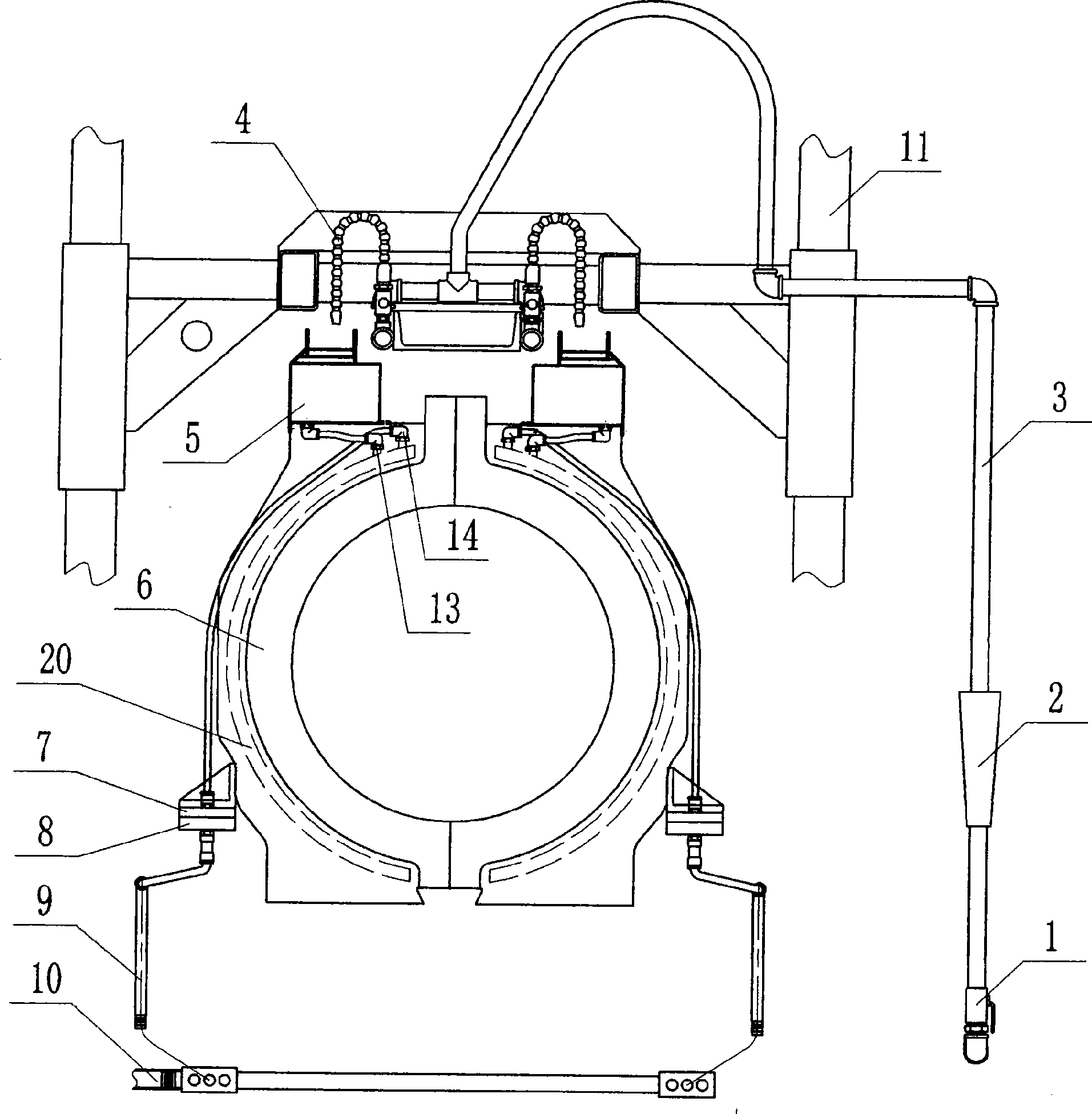

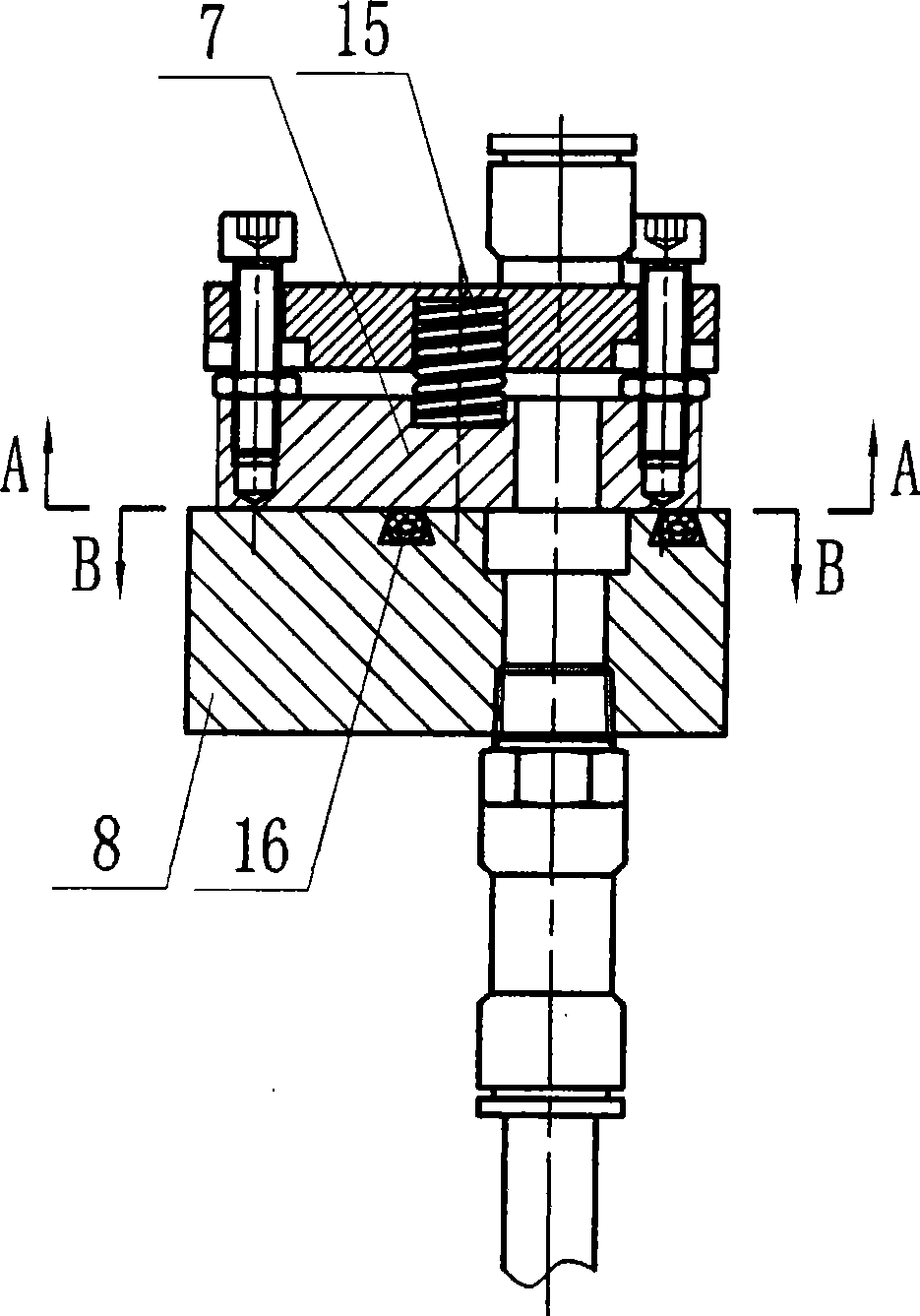

[0031] The method for cooling a corrugated pipe forming module includes sequentially performing a cooling liquid supply step, a module cooling step, and a cooling liquid return step, wherein: the cooling liquid supply step includes a pressure-free liquid inlet step at the cooling liquid inlet, and the cooling liquid of the module is The steps include the step of circulating cooling in the inner cavity of the module, and the step of liquid return of the cooling liquid includes the step of vacuum negative pressure liquid return at the outlet of the cooling liquid.

[0032] The non-pressure inlet step of the coolant inlet is to install a coolant liquid storage device connected to the coolant inlet on the corrugated forming module body, and the coolant liquid storage device is a liquid containing device arranged on the upper body of the forming module groove or fixedly installed on the top of the forming module independent liquid tank, using the weight of the cooling liquid and vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com