Hollow mold for filling cast-in-situ concrete

A hollow carcass, cast-in-situ concrete technology, which is applied in the on-site preparation of building components, formwork/template/work frame, structural elements, etc., can solve the problem that the width of the concealed rib in the floor cannot be effectively guaranteed to be consistent with the design width. , inconvenient lateral limit and other problems, to achieve the effect of high rigidity, excellent anti-vibration performance and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

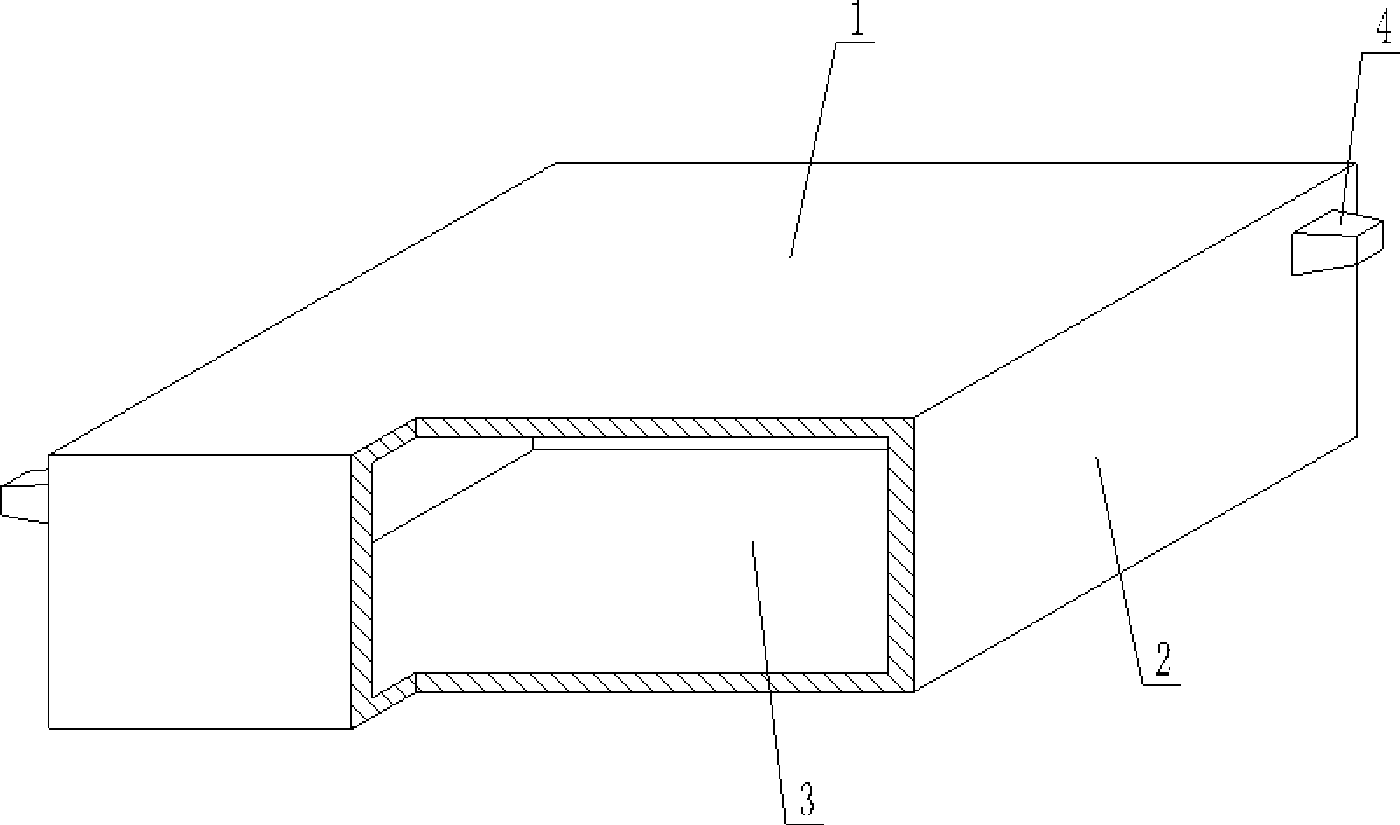

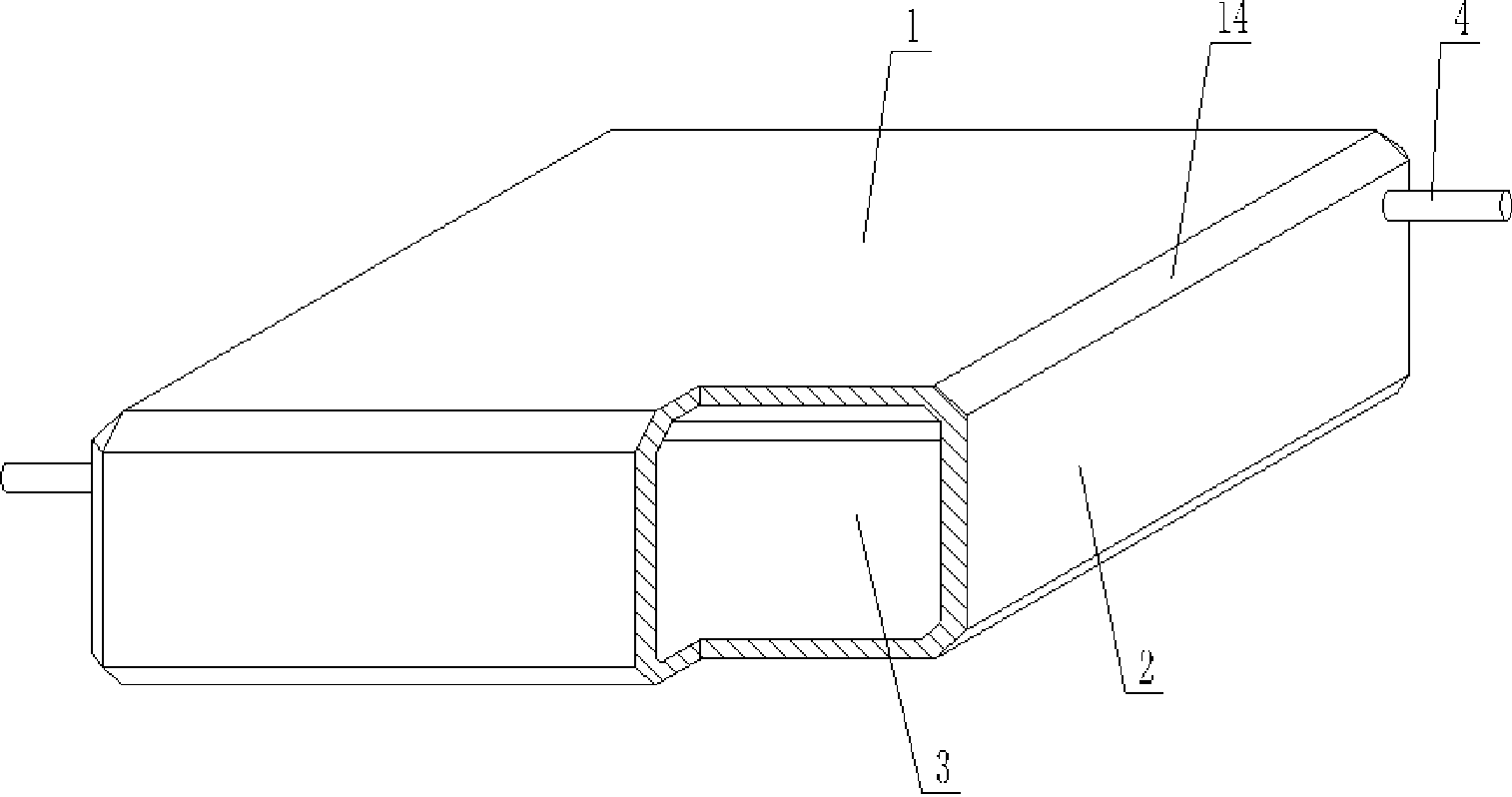

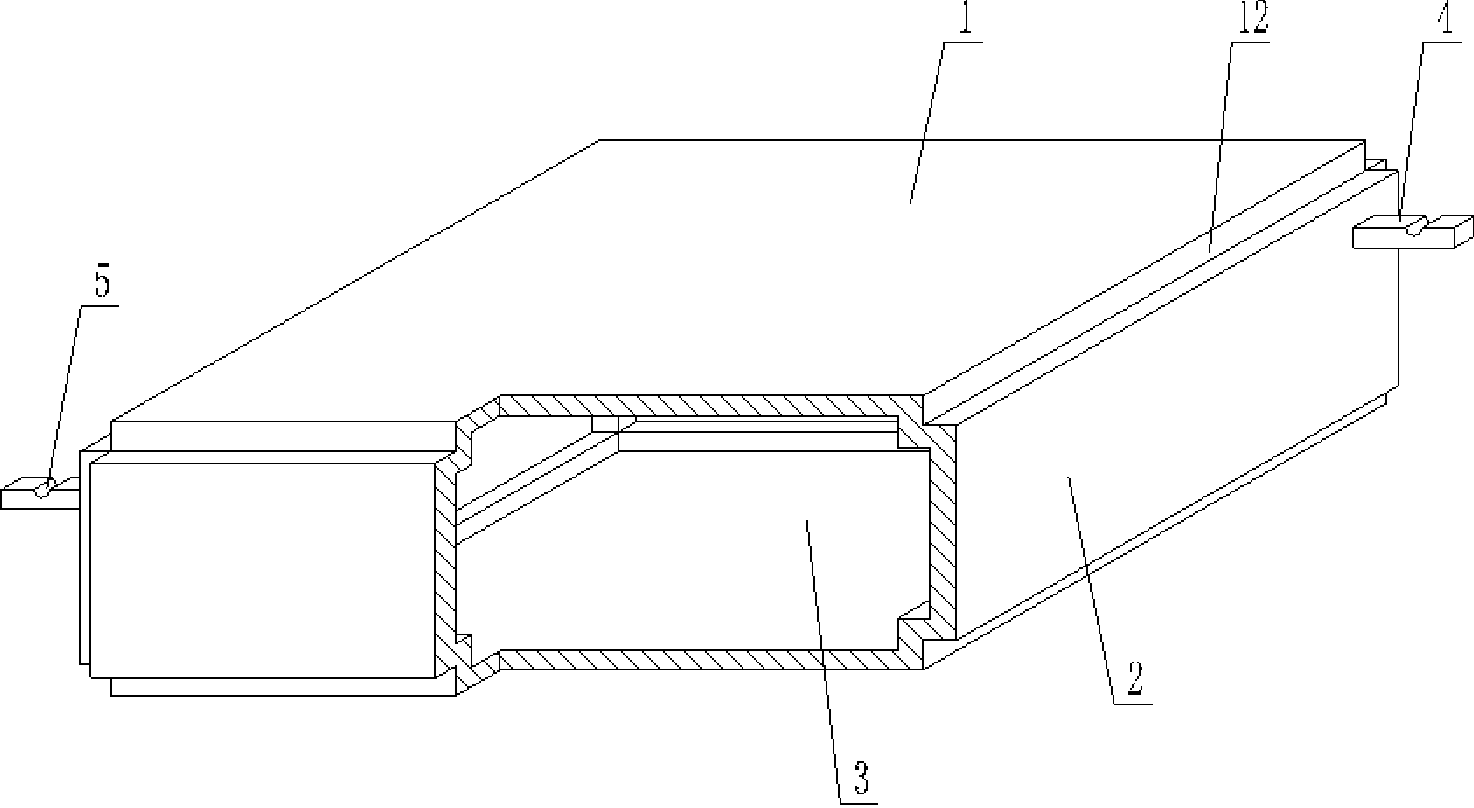

[0076] As shown in the accompanying drawings, the present invention comprises a hollow carcass 1, the hollow carcass 1 having a cavity 3 enclosed by an outer wall 2, and is characterized in that the side outer wall 2 of the hollow carcass 1 is provided with cantilevered ribs Spacing width limiting member 4 and rib spacing width limiting member 4 are at least one of rods, short steel bars, bumps, and brackets. The grooves 15 provided on the hollow carcass 1 are connected to the holes 17 of the hollow rods 18 . In the accompanying drawings, 1 is the hollow carcass, 2 is the outer wall, 3 is the cavity, and 4 is the rib spacing width limiting member. In the following drawings, those with the same number have the same description. Such as figure 1 As shown, the outer wall 2 encloses a hollow carcass 1 with a cavity 3 formed, and the side outer wall 2 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com