Micro radiator fan device

A micro heat dissipation and fan technology, which is applied to pump devices, electromechanical devices, and components of pumping devices for elastic fluids, etc., can solve the problems of lack of magnetic conductive back iron structure, insufficient torque, low number of turns and poles, etc. , to achieve the effect of improving convection efficiency and increasing magnetic flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a further understanding and recognition of the structure, purpose and effect of the present invention, the detailed description is as follows in conjunction with the accompanying drawings.

[0041] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the accompanying drawings, and the embodiments listed in the accompanying drawings are only auxiliary descriptions, in order to facilitate understanding of the technical solutions of the present invention, but the technical means of the present invention are not Not limited to the figures listed.

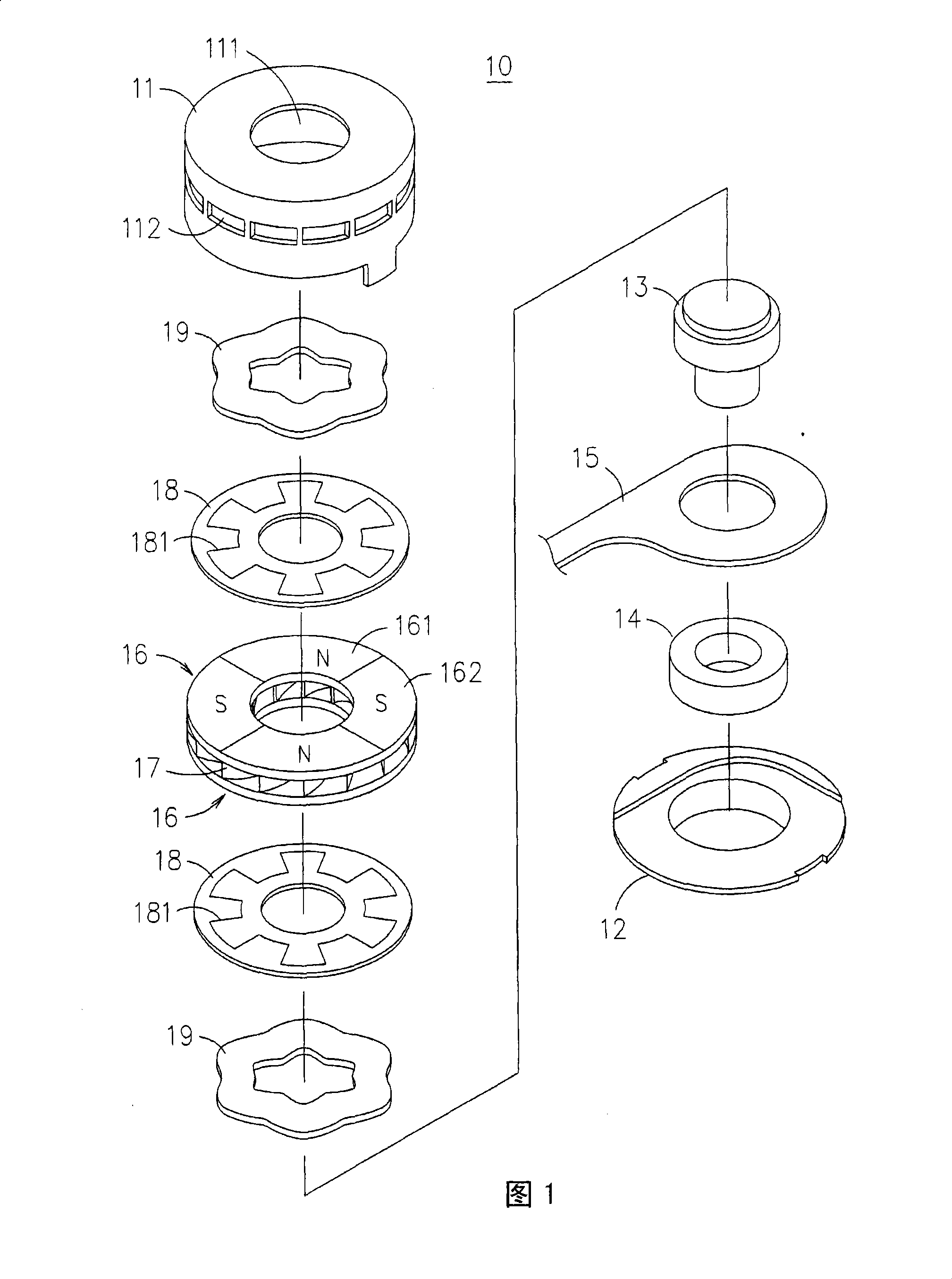

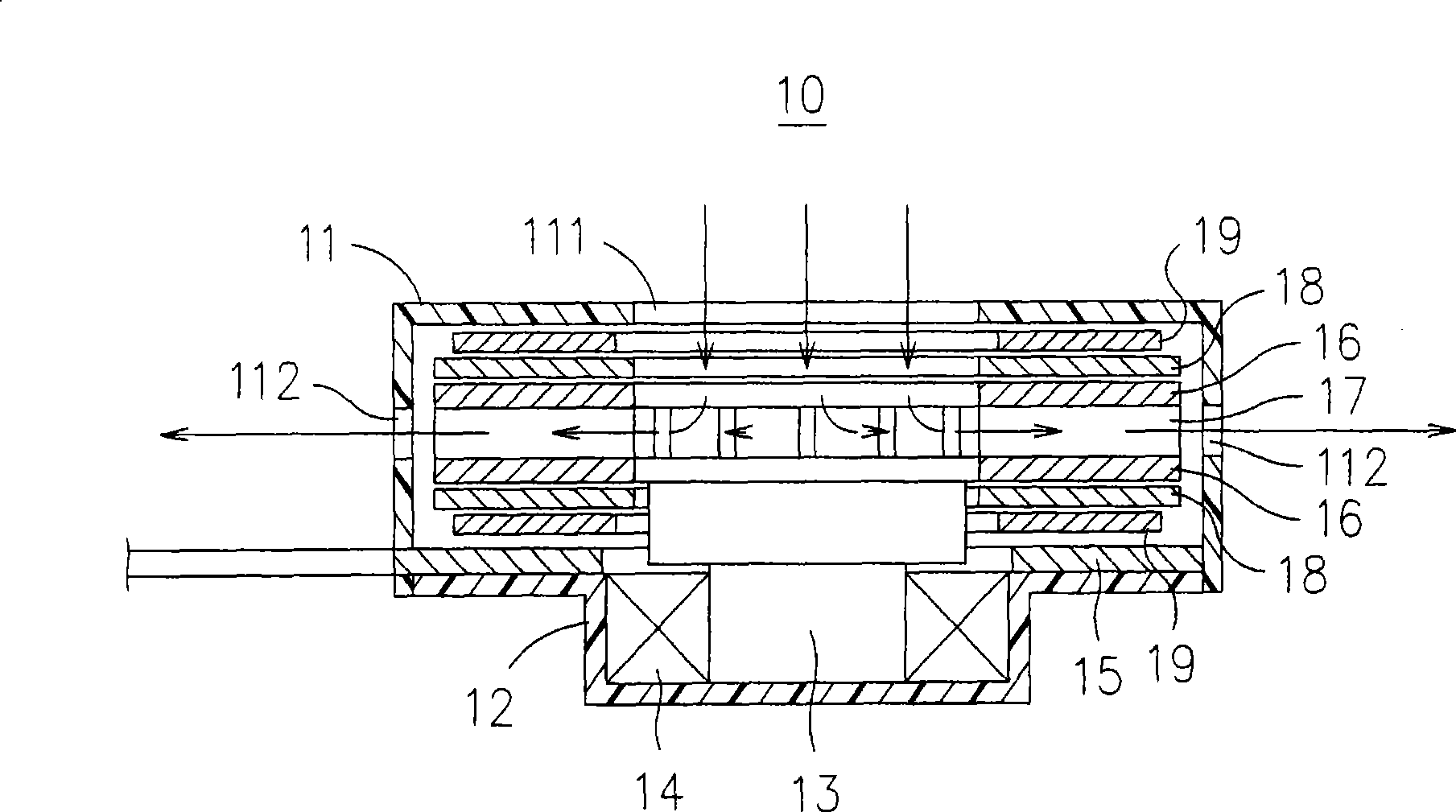

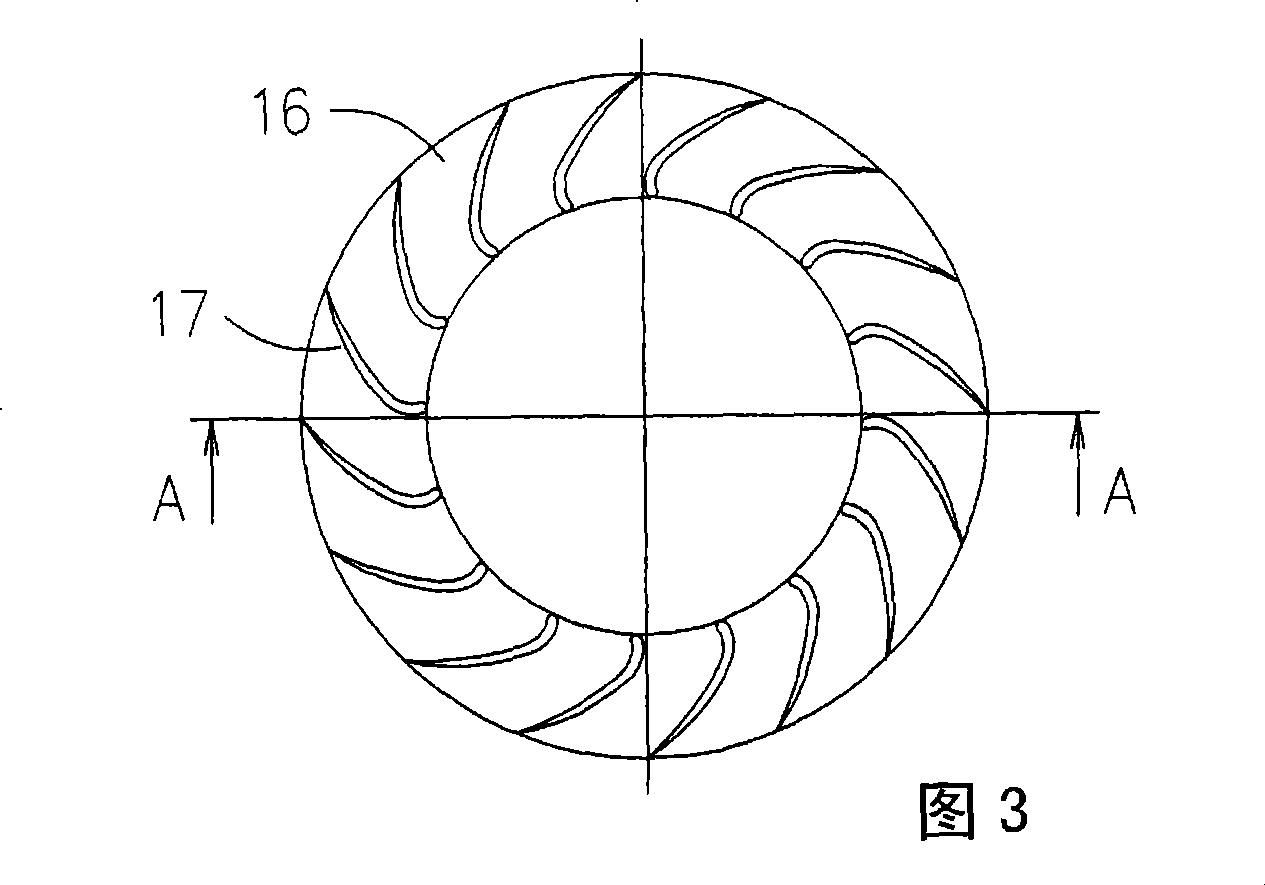

[0042] Please refer to Figure 1 and figure 2 As shown, the micro cooling fan device 10 provided by the present invention includes a main body composed of a cylindrical outer sleeve 11 and a flat circular base 12, and a rotating shaft 13 is arranged in the main body. One axial end is pivotally connected to the base 12 by a bearing 14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com