Cam control device for dust keeper turning plate

A technology of cam control and dust preventer, which is applied in the field of trolleys in ironworks, can solve the problems affecting the safety of cleaning personnel and the wear of the load-bearing surface of supporting wheels, so as to improve the safety factor, prevent jamming, and quickly clean and inspect the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

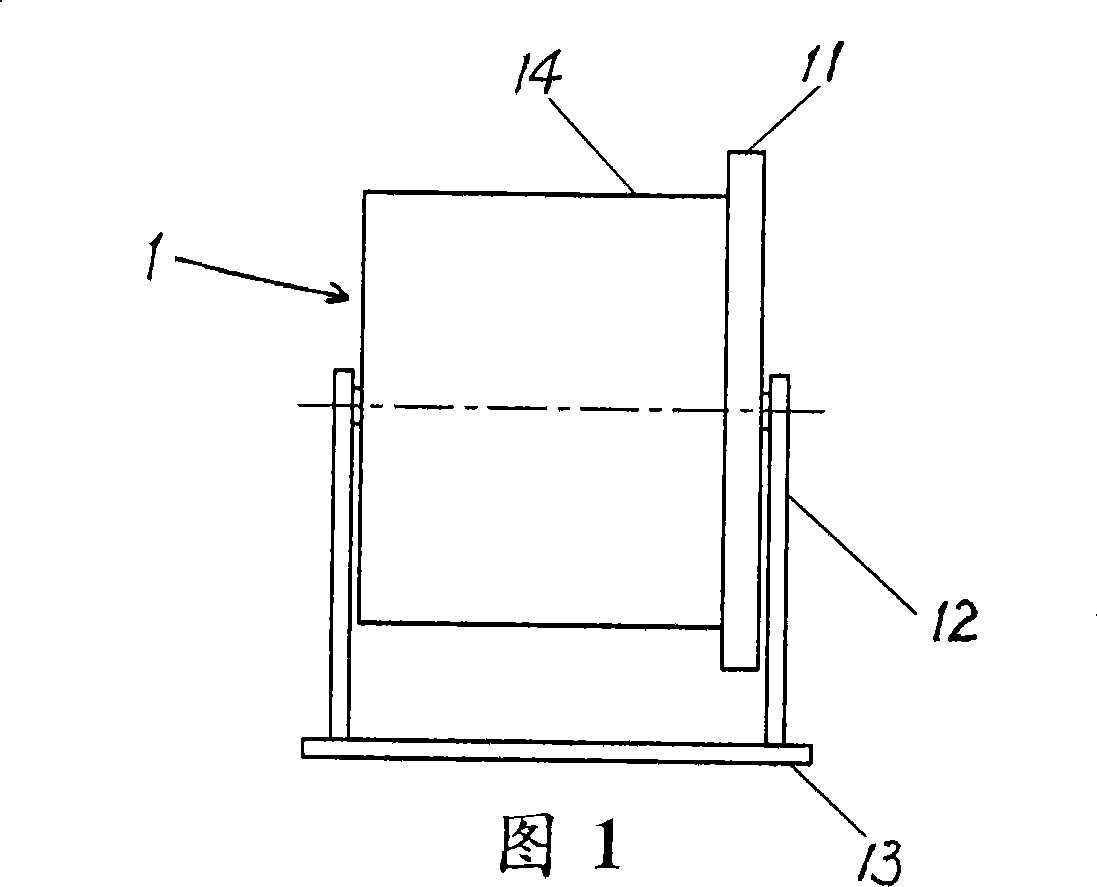

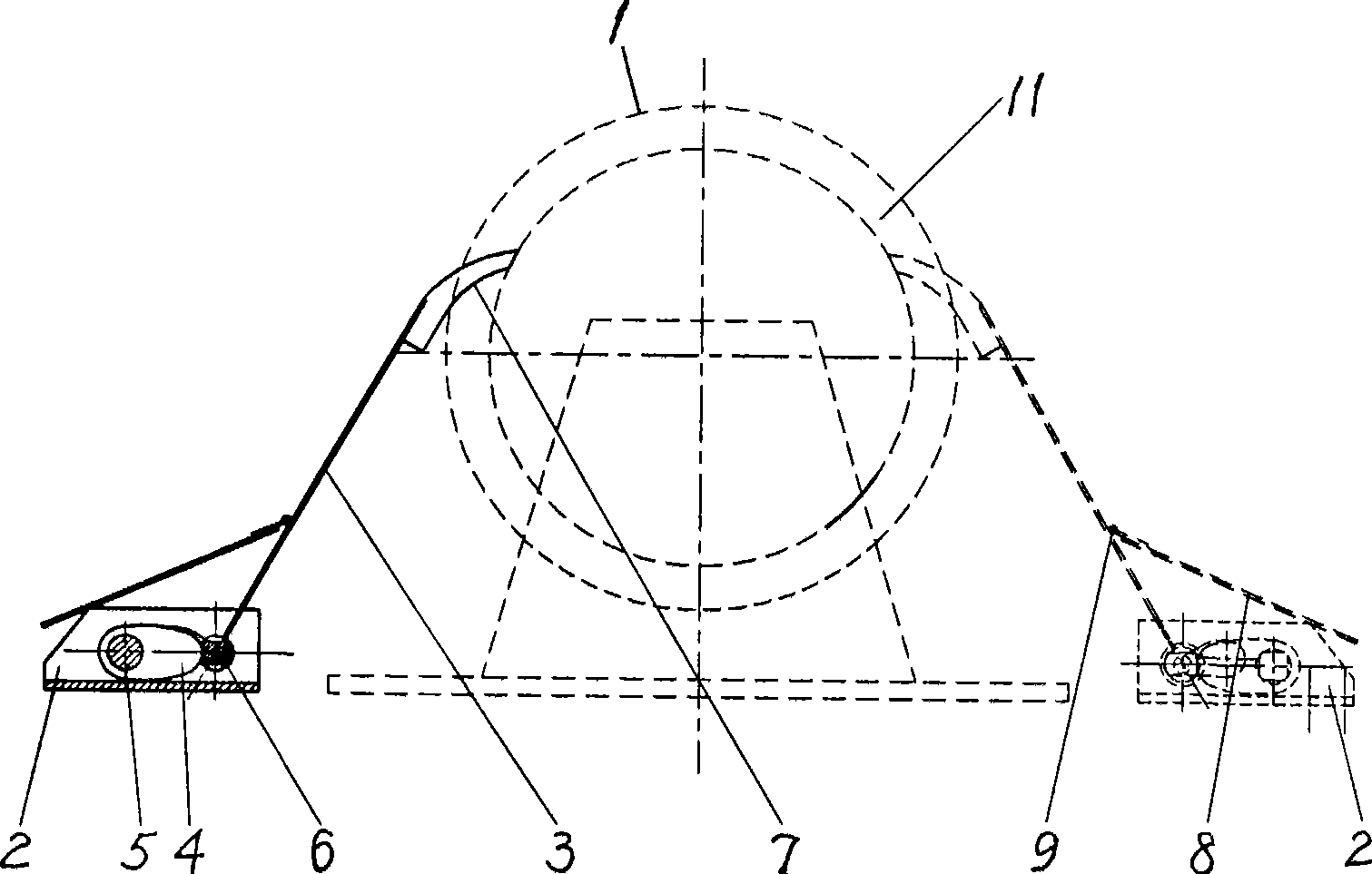

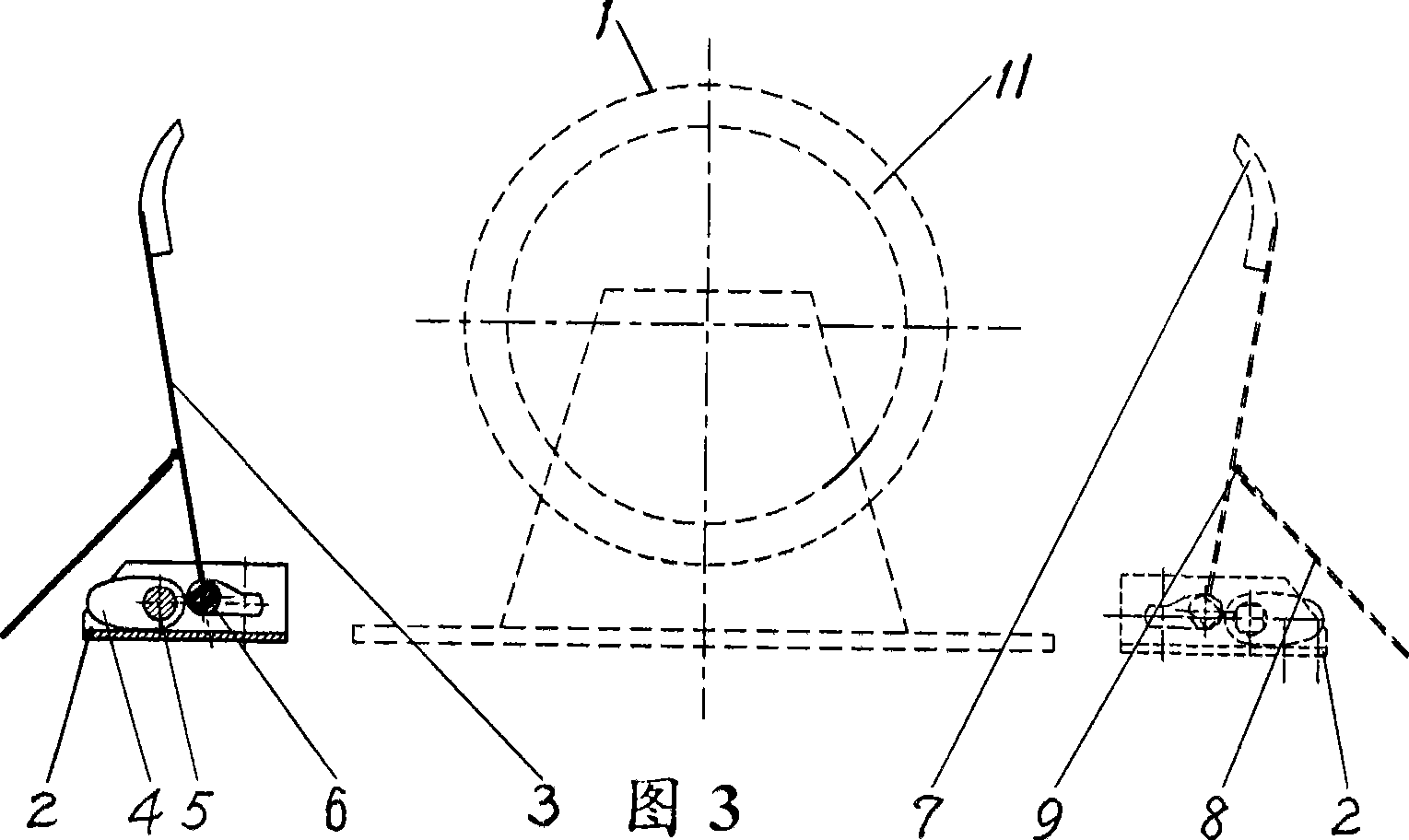

[0023] see figure 2 And Fig. 3, a kind of cam control device that is used for dustproof device turnover plate of the present invention is installed on the dustproof device, and dustproof device is equipped with dustproof device casing 2 and dustproof device turnover plate 3. The cam control device is installed beside the side of the supporting roller 1, and can be installed on one side of the supporting roller 1, and can also be installed on both sides of the supporting roller 1.

[0024] A cam 4 is housed in the dustproof device casing 2, and a camshaft 5 is fixedly arranged on the cam 4. The axle end of camshaft 5 is equipped with wrench, is convenient to rotate camshaft 5. Cam cover plate 8 is housed above cam 4. The upper end of the cam cover plate 8 is connected with the dust-proof flap 3 through a living hinge 9 . The cam cover plate 8 has a certain discharge angle during work, which can prevent the material blocks from accumulating on the cover plate surface, and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com