A dust recycling system for enhanced availability of Corex

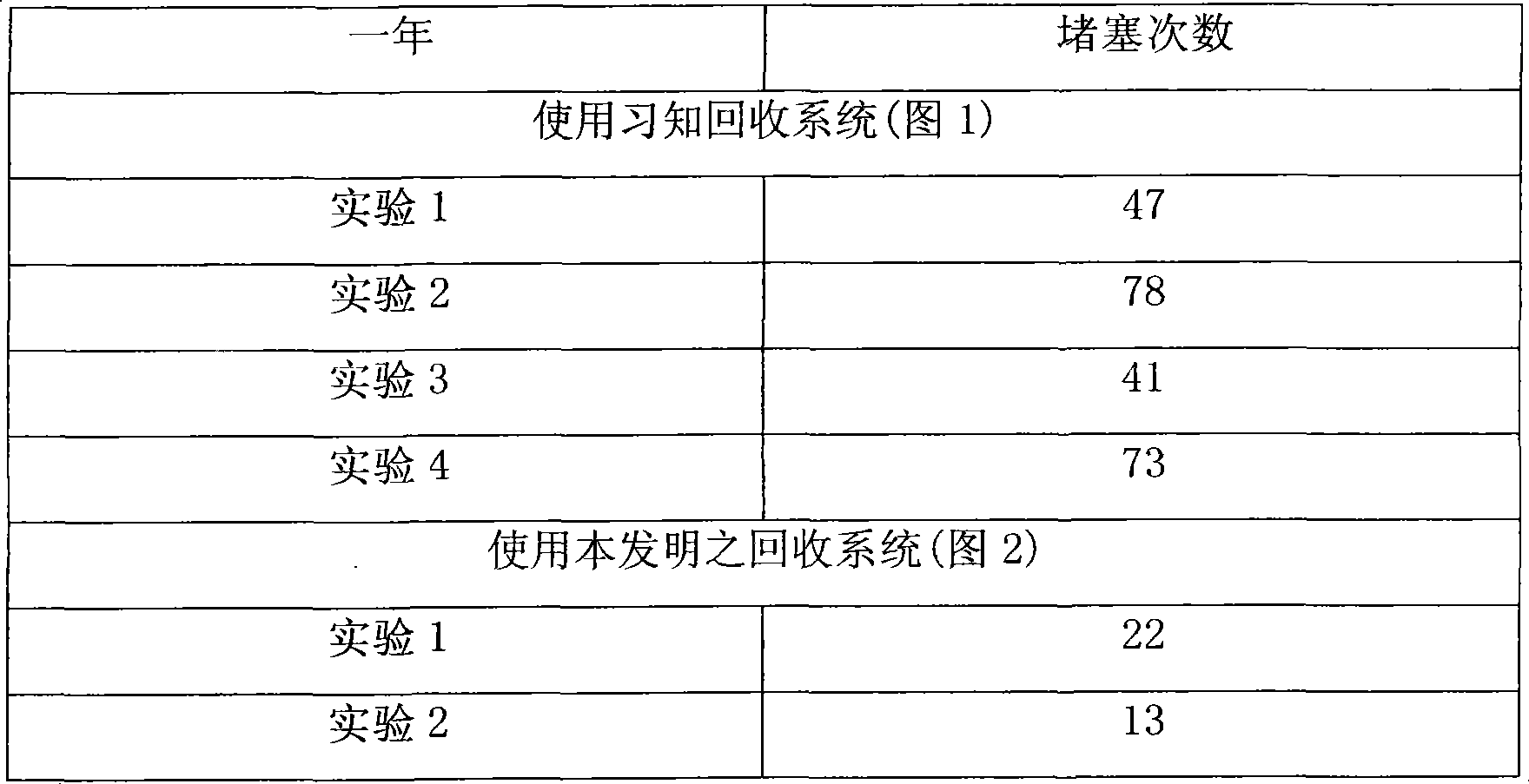

A dust recovery and dust technology, which is used in the improvement of process efficiency, metal processing, sustainable manufacturing/processing, etc., can solve the problems of dust recovery system blockage, cooling system leakage into the furnace, etc., to avoid machine downtime, simple and effective cleaning and maintenance characteristics, improved availability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

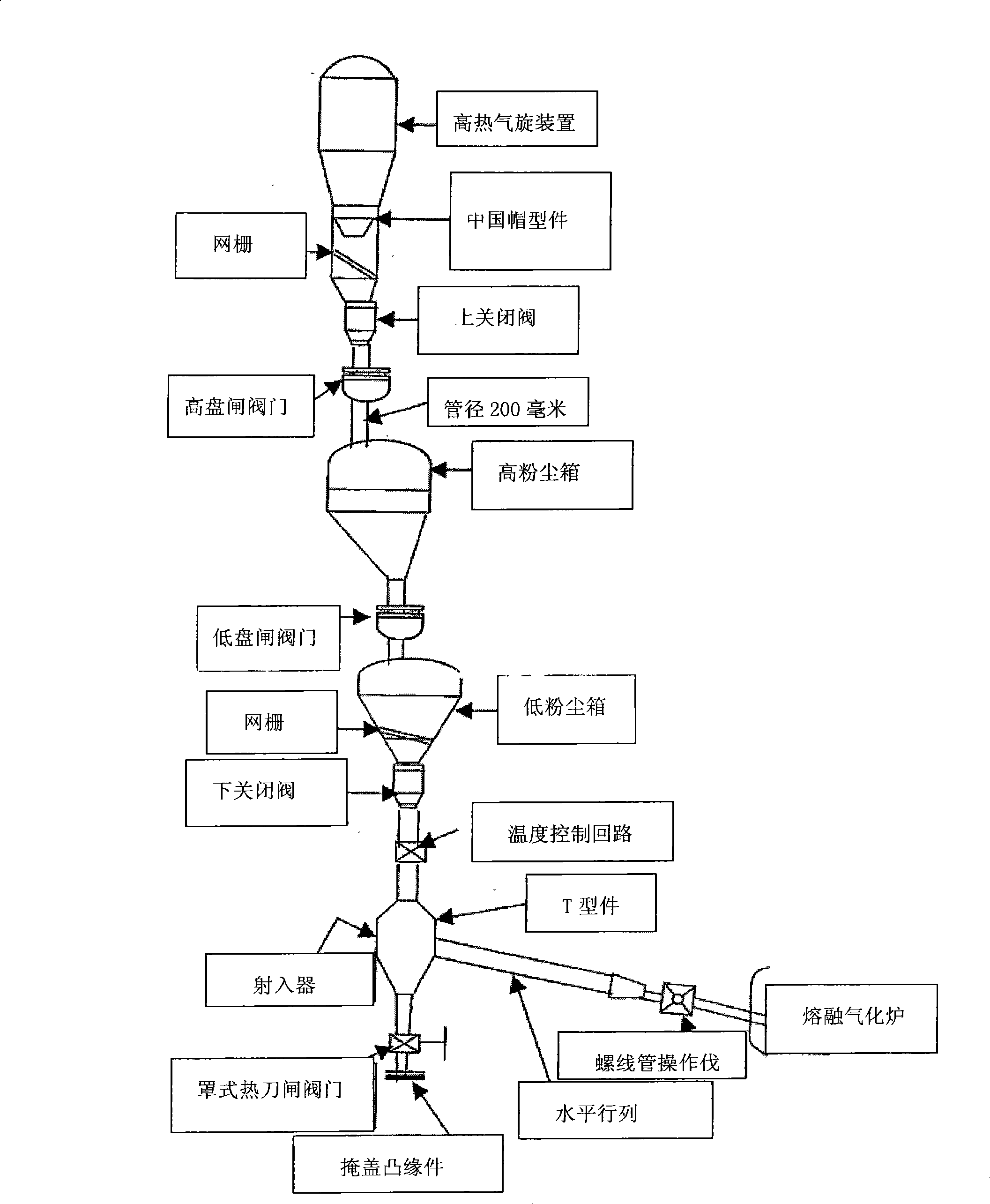

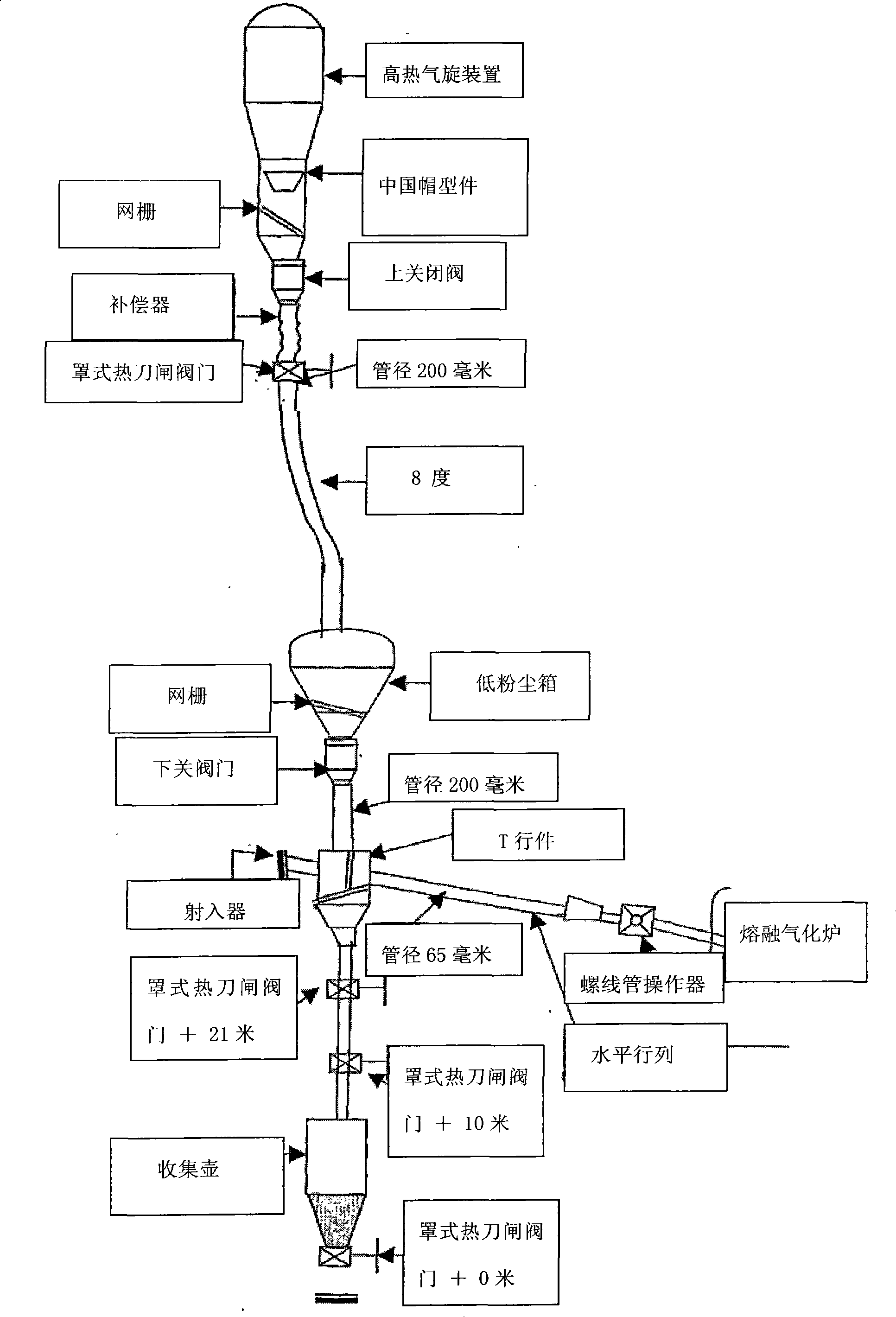

[0048] Please see first figure 1 , which already has an array of dust recovery systems to capture dust from the reducing gas and inject it back into the melter-gasifier.

[0049] Such as figure 1 As shown, the ranks of the existing dust recovery system basically include high heat cyclone device (HGC), upper shut-off valve (USV), high dust box (UDB), low dust box (LDB), lower shut-off valve (LSV), dust ejector Inlet systems, T-pieces (TP) and dust burners. The operative components of all dust recovery systems mentioned above are operatively connected to the lower disk gate valve (LDG) via vertical conduits and the upper disk gate valve (UDG) as shown in the figure.

[0050] Depend on figure 1 It is obvious that the existing line of dust recovery systems, in the high heat cyclone device (HGC), includes a Chinese hat (Chinese Hat) as shown in the figure to create vertex formation in the high heat cyclone device To separate the coarse particles from the fine dust, the dust obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com