Soy milk preparation method and fuzzy control electrical heating full automatic soyabean milk machine

A soymilk machine, a fully automatic technology, applied in food preparation, beverage preparation devices, dairy products, etc., can solve the problems of high manufacturing cost, slow motor speed, complex circuit structure, etc., and achieve low cost, high cost performance and simple circuit structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

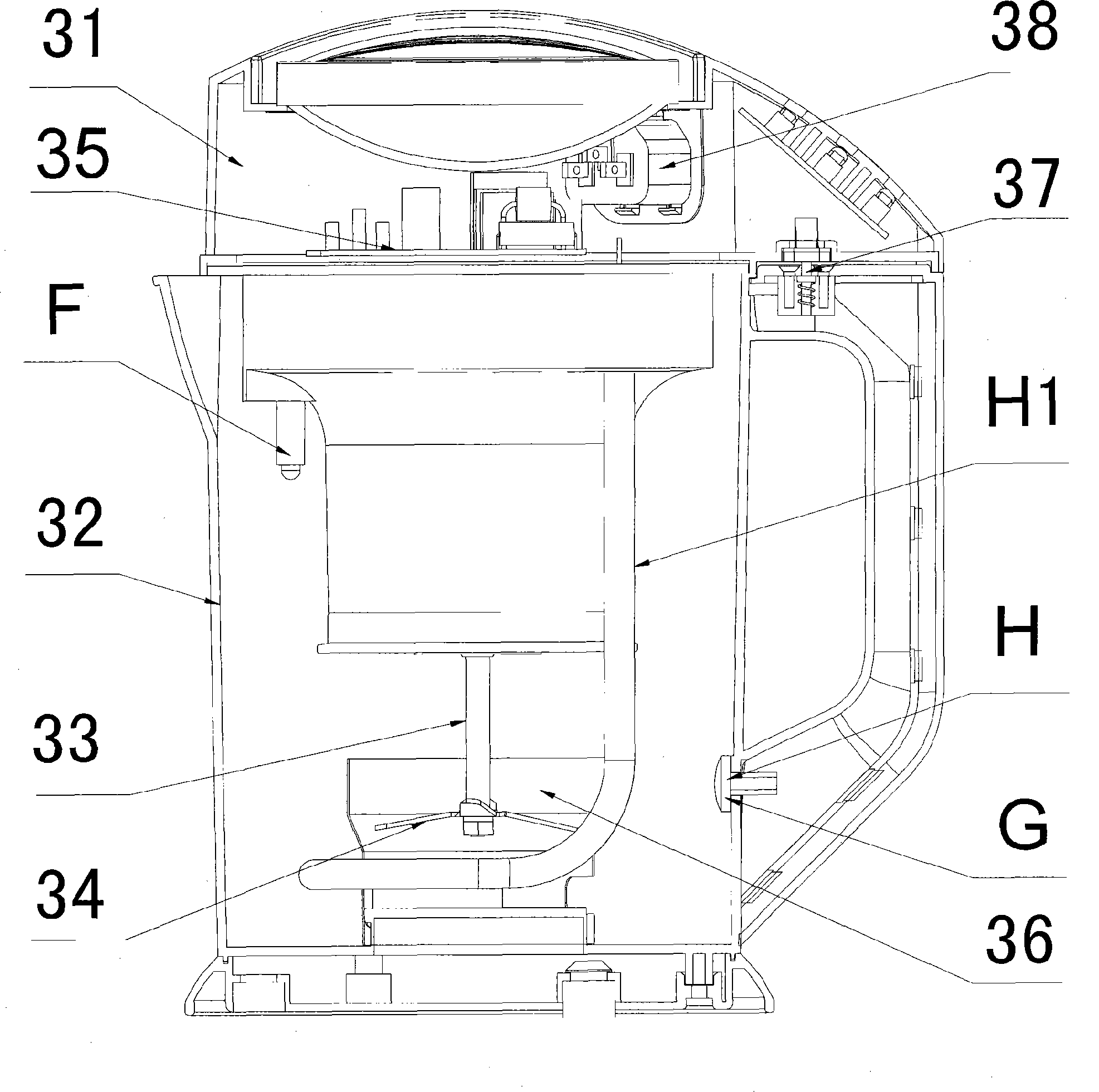

[0030] Example: such as figure 1 Shown is a structural diagram of a specific embodiment of the fuzzy control electric heating automatic soybean milk machine of the present invention: it consists of a machine head 31, a cup body 32, a motor M1, a motor drive shaft 33, a rotating blade 34, a heating element H1, a temperature measuring Sensor head H, anti-overflow sensor head F, anti-dry sensor head G, control circuit board 35, deflector 36, coupler 37 and power socket 38 constitute.

[0031]The machine head 31 is fastened on the cup body 32 , and the control circuit board 35 is placed in the machine head 31 . The motor M1 ( figure 1 (not visible in the middle) is placed in the machine head 31, electrically connected to the control circuit board 35, and at the same time, the motor transmission shaft 33 on it extends into the cup body 32 and fixes the rotating blade 34, and the deflector 36 is fixed on the bottom of the cup body 32 and is located Rotate the blade 34 below. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com