Round steel end chamfering machine

A technology of chamfering machine and round steel, which is applied in the direction of metal extrusion dies, etc., to achieve the effect of simple setting structure, safe operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

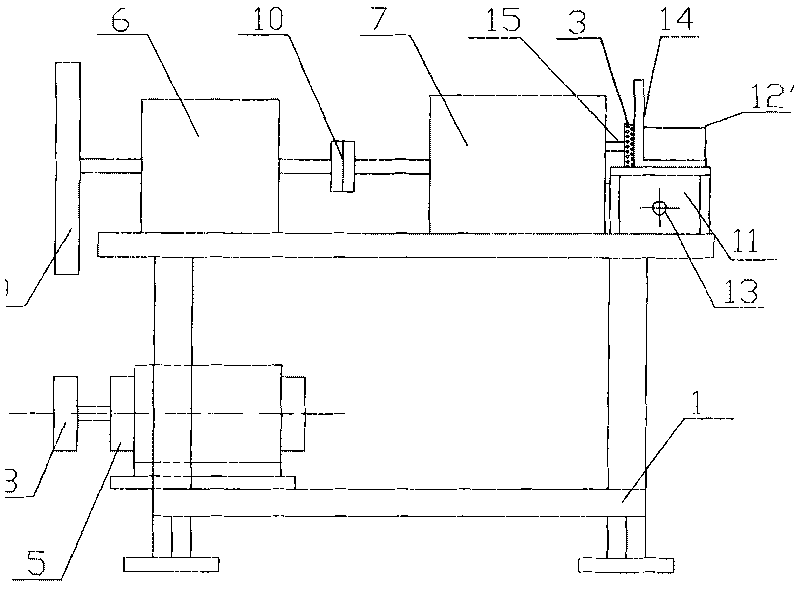

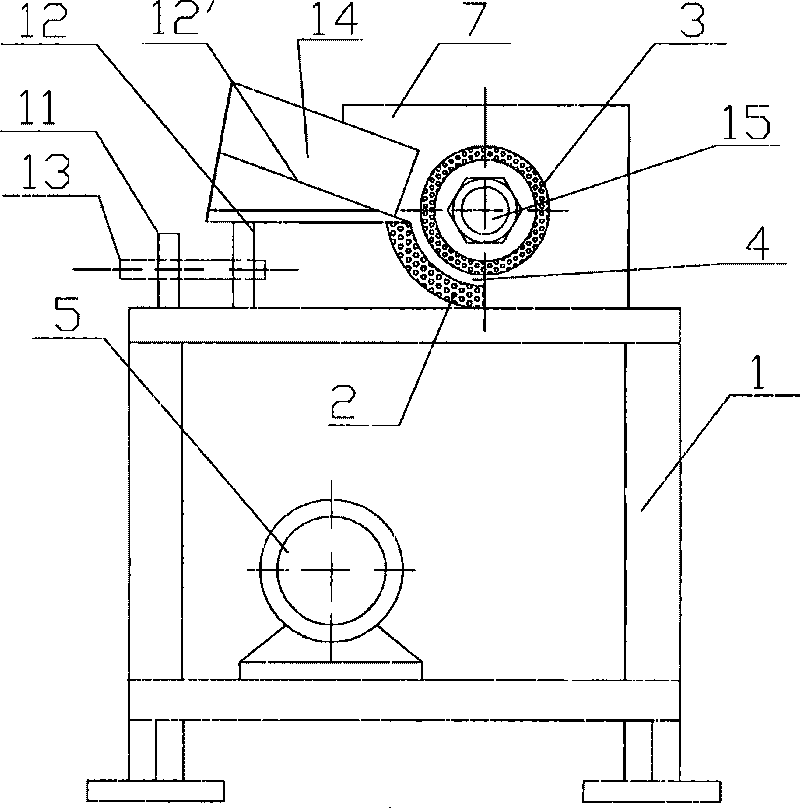

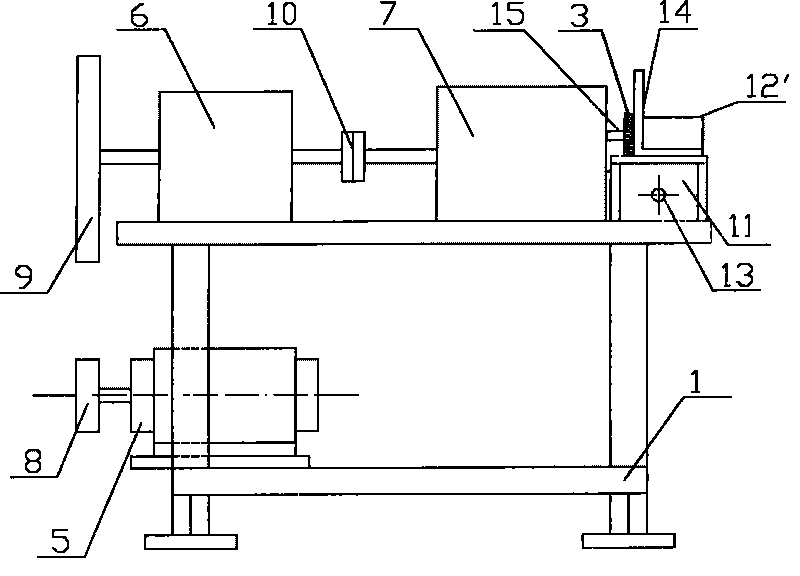

[0016] Such as figure 1 and figure 2 As shown, the round steel end chamfering machine of the present invention comprises a frame 1, and a power unit and a mold group are arranged on the frame 1, and the mold group includes a flower tooth arc mold 2 and a flower tooth tapered mold 3 arranged concentrically, The smaller end diameter of the flower tooth cone mold 3 faces the outside of the frame, and the round steel processing channel 4 is formed between the flower tooth cone mold 3 and the flower tooth arc mold 2, and the power unit communicates with the flower tooth cone mold 3 through the transmission device. Drive connection. Described power unit is electric motor 5, and described transmission device comprises reduction box 6 and transmission case 7; The output shaft of described motor 5 is provided with small belt pulley 8, and the input shaft of described reduction box 6 is provided with large belt pulley 9. The small pulley 8 and the large pulley 9 are connected by bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com