Bar for a warp knitting machine

A technology of warp knitting machine and bar, which is applied in the field of bar for warp knitting machine, which can solve the problem of high cost and achieve the effect of small quality, small resistance and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

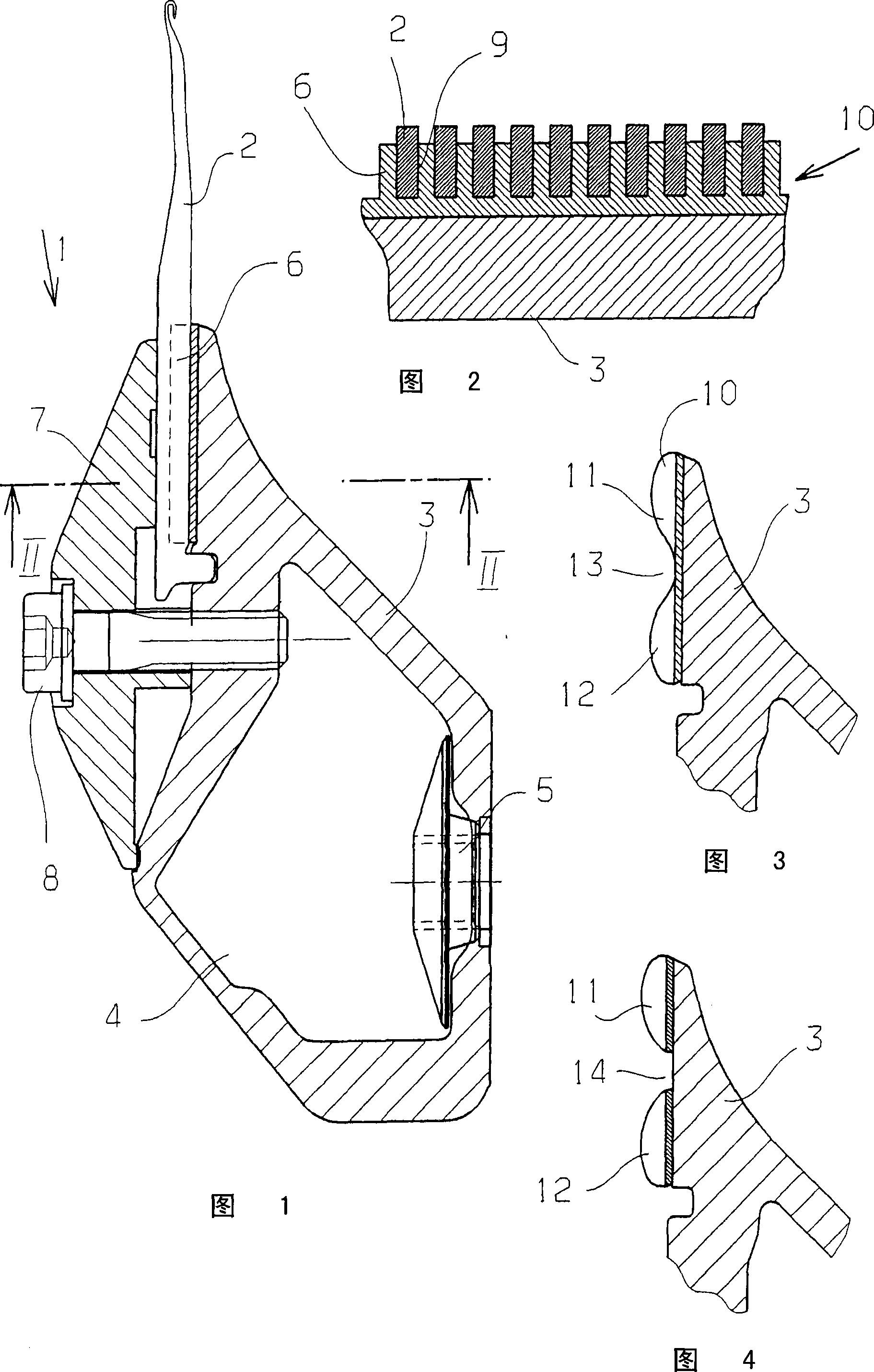

[0031] The needle bed 1 shown in FIG. 1 has knitting needles 2 . The needle bed 1 has a body 3 made of carbon fiber reinforced plastic material, which surrounds a cavity 4 and is provided with fixing means 5 for fixing the bar 1 in a weaving machine (not shown in detail).

[0032] The knitting needles 2 are arranged in the needle holder 6 and are held there by the cover plate 7 . The cover plate 7 is connected with the body 3 by bolts 8 . A plurality of such bolts 8 can of course be provided over the length of the bar 1 .

[0033] A groove 9 is provided for each needle 2 . This recess is formed in the plastic coating 10 in which the needle holder 6 is formed. The plastic coating 10 is made of a plastic that is adhesive in the uncured state, in particular a two- or more-component adhesive, which is formed as a synthetic resin or based on a polyurethane base.

[0034] The plastic coating is suitably applied using a pneumatically or hydraulically or otherwise driven glue appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com