Bearing support

A technology of heavy support and truss platform, which is applied to the field of continuous beam pier top load-bearing brackets by the suspension casting method, can solve the problems of small operation space, large waste, low material reuse rate, etc., and achieves the effect of convenient assembly and disassembly and simple force bearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

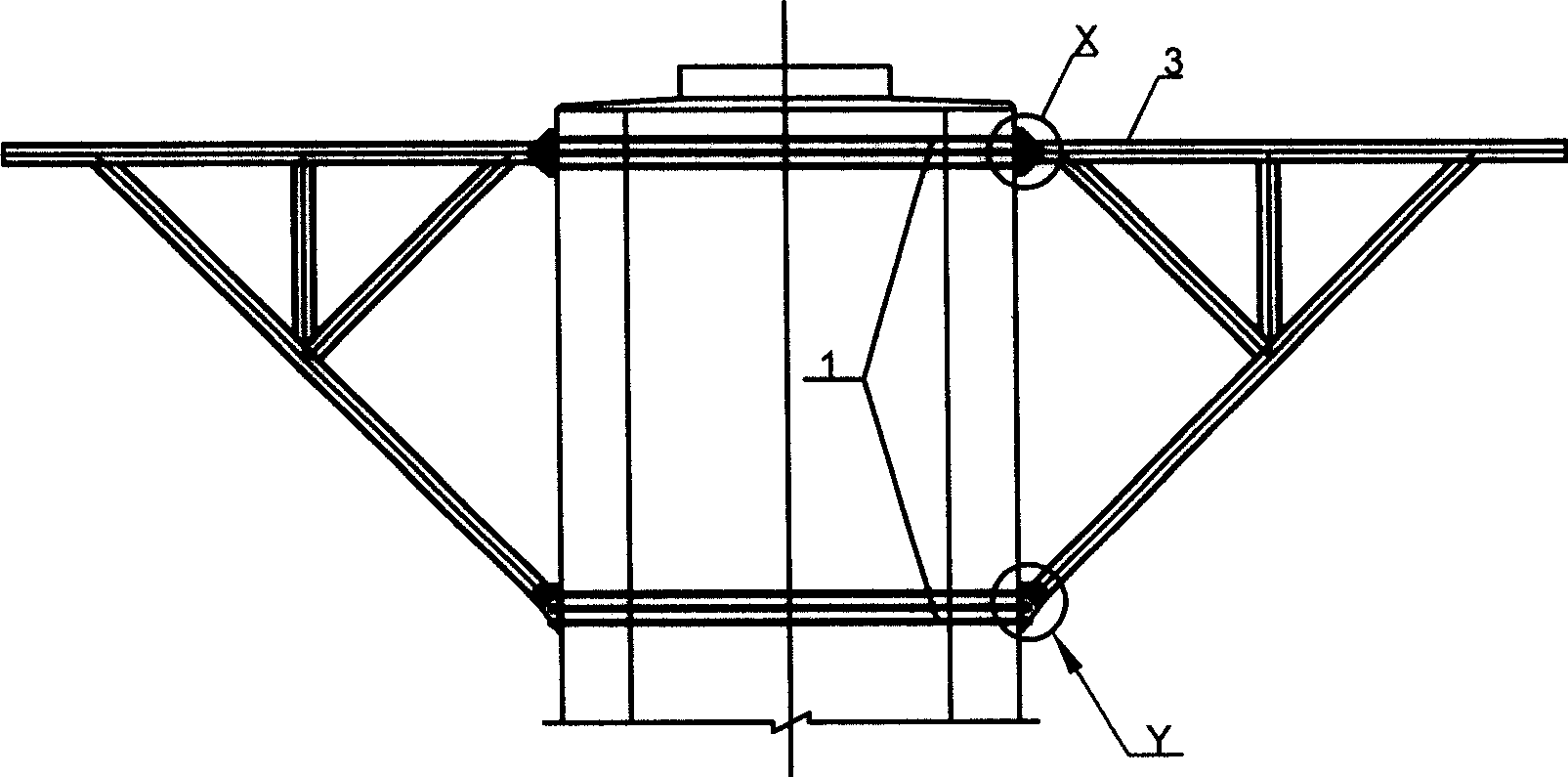

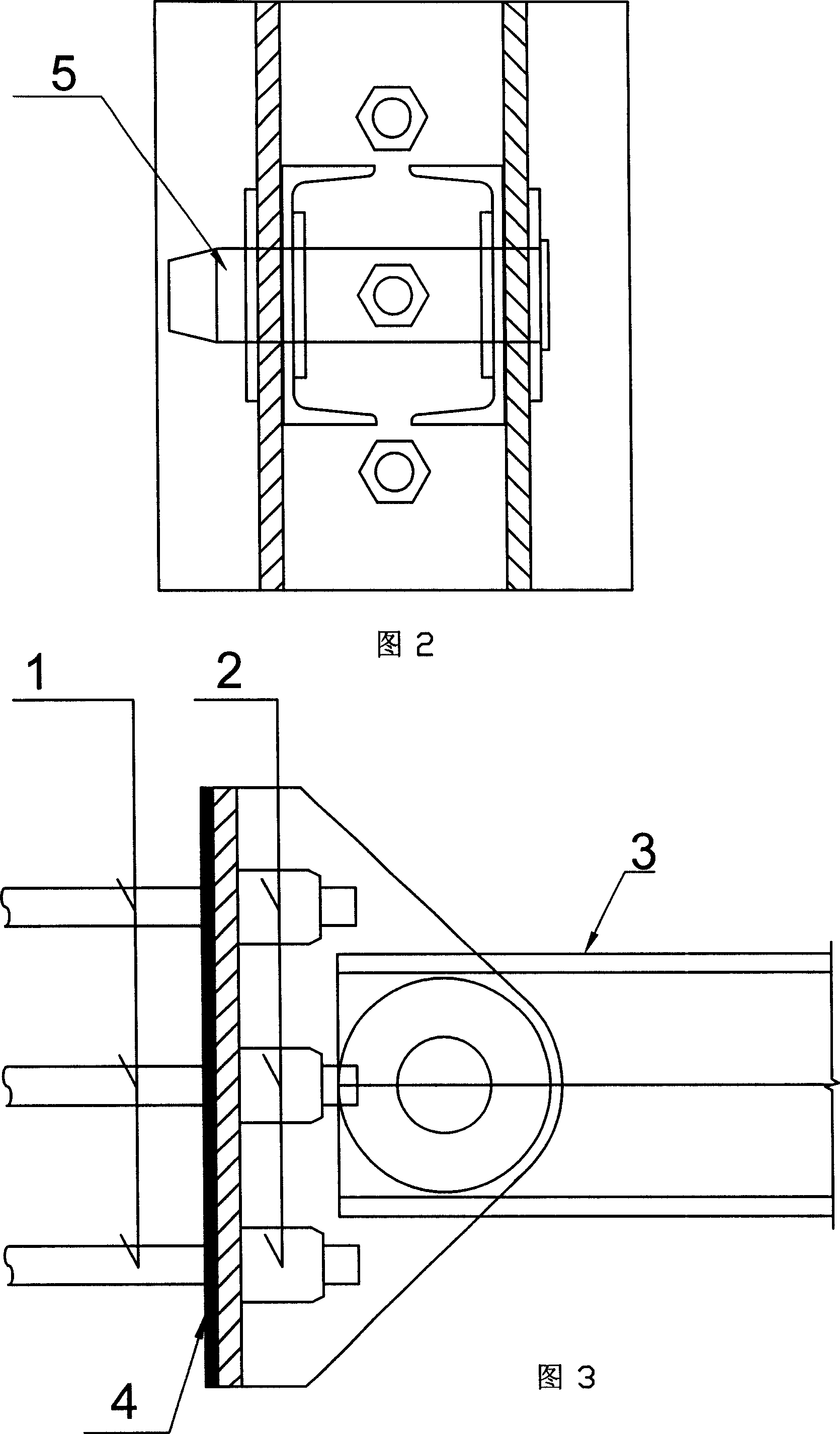

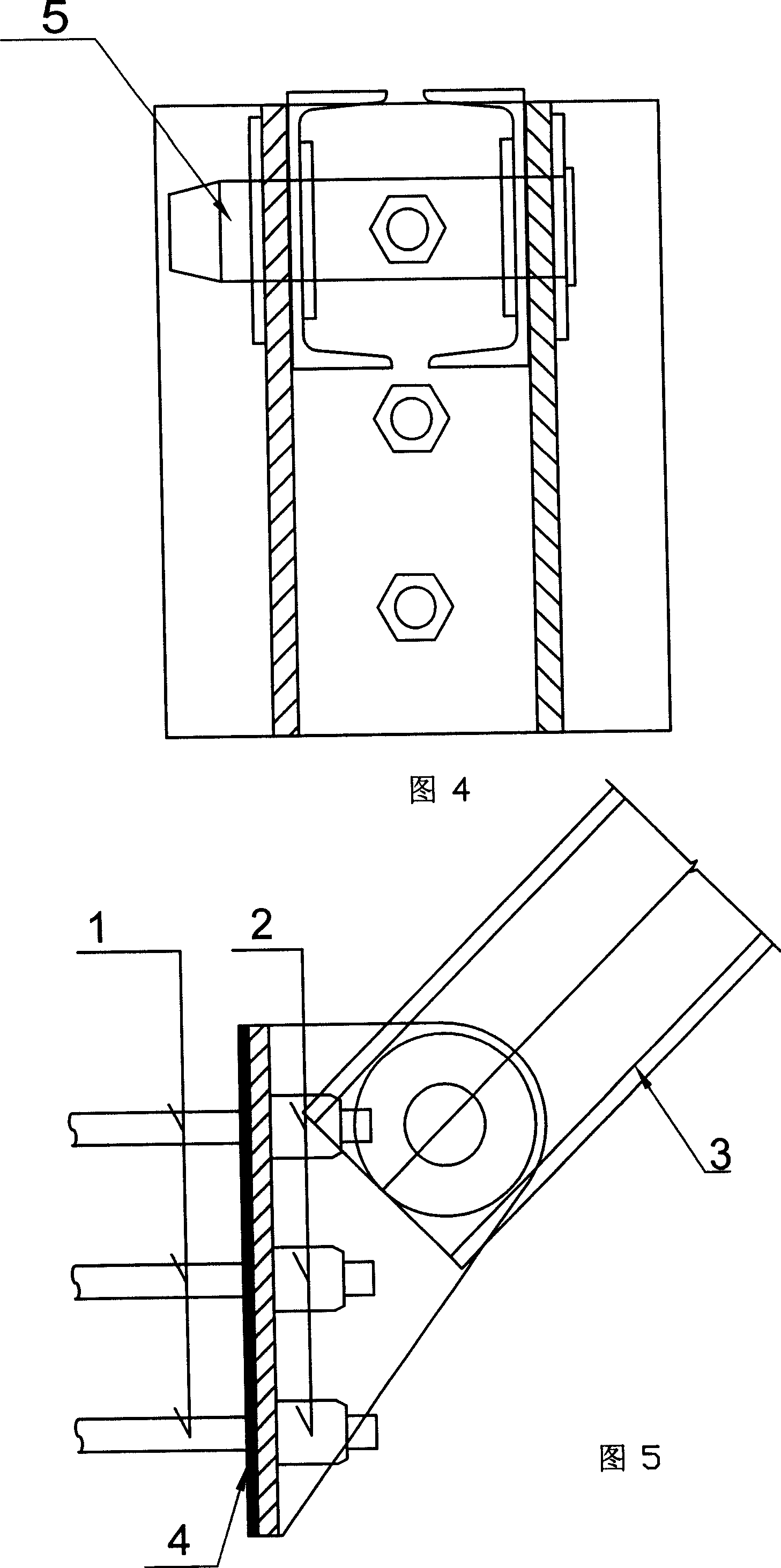

[0015] Consists of symmetrically arranged shaped truss platforms 3 such as figure 1 As shown, the upper end side of the forming truss platform 3 is connected to the upper hinge seat X through the connecting steel pin 5, and the lower end side of the forming truss platform 3 is connected to the lower hinge seat Y through the connecting steel pin 5. The upper hinge seat X and The lower hinge seat Y is connected to the symmetrically arranged upper hinge seat X and the lower hinge seat Y via the connecting shaft and the JM anchor 2.

[0016] The bottom surfaces of the upper hinge seat X and the lower hinge seat Y are provided with pressure-resistant rubber pads 4, as shown in Figures 3 and 5. Place

[0017] The connecting shaft described above is high-strength finish-rolled rebar 1.

[0018] There are at least two connecting shafts.

[0019] The embodiment of this device is composed of high-strength finish-rolled rebar 1, JM anchorage 2, forming truss platform 3, upper hinge se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com