Rail type conveyer

A conveyor, track-type technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of easy chain jumping, chain breakage, insufficient transfer speed, etc., to achieve convenient clamping distance, easy installation and disassembly , the effect of fast delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

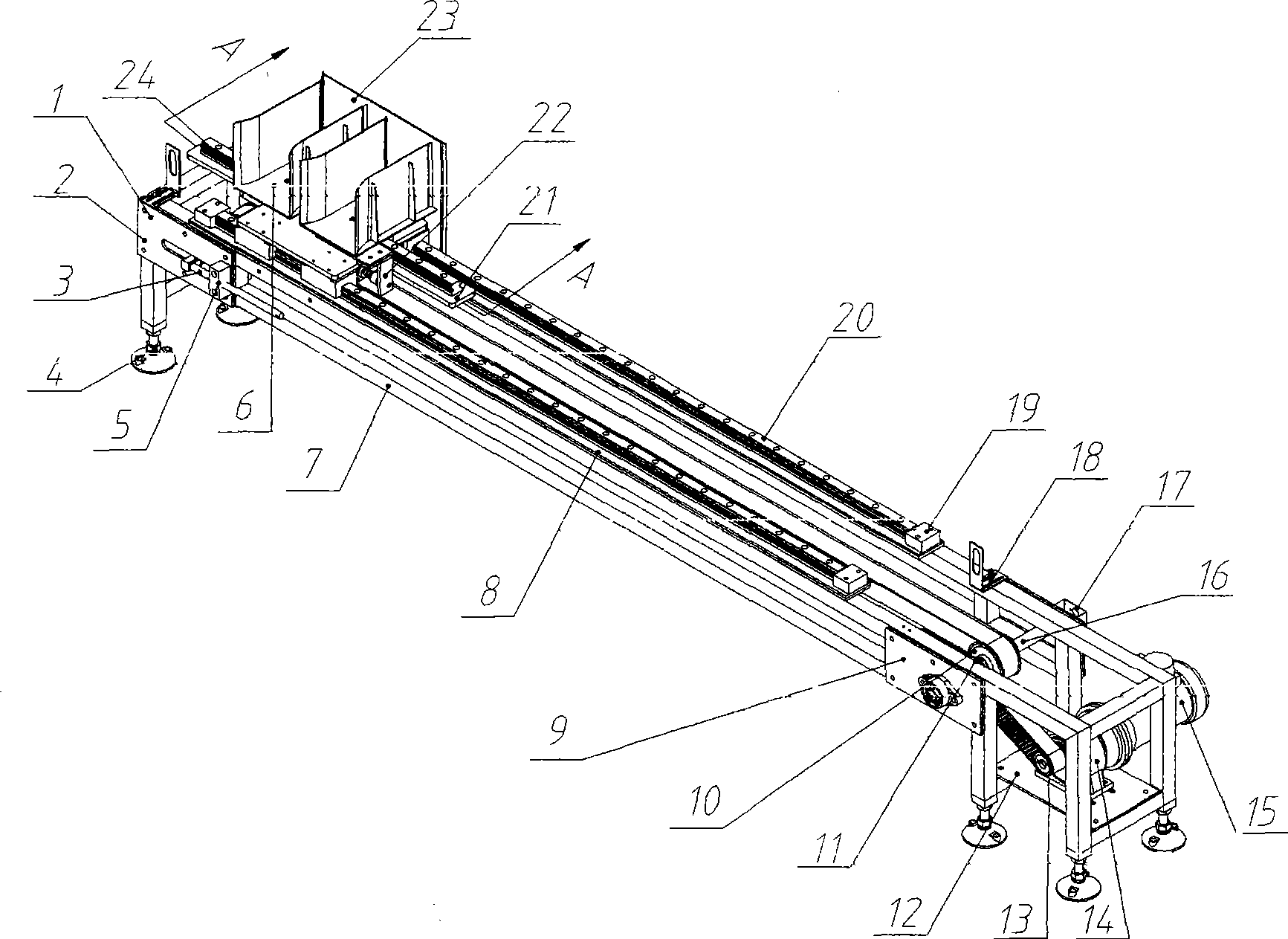

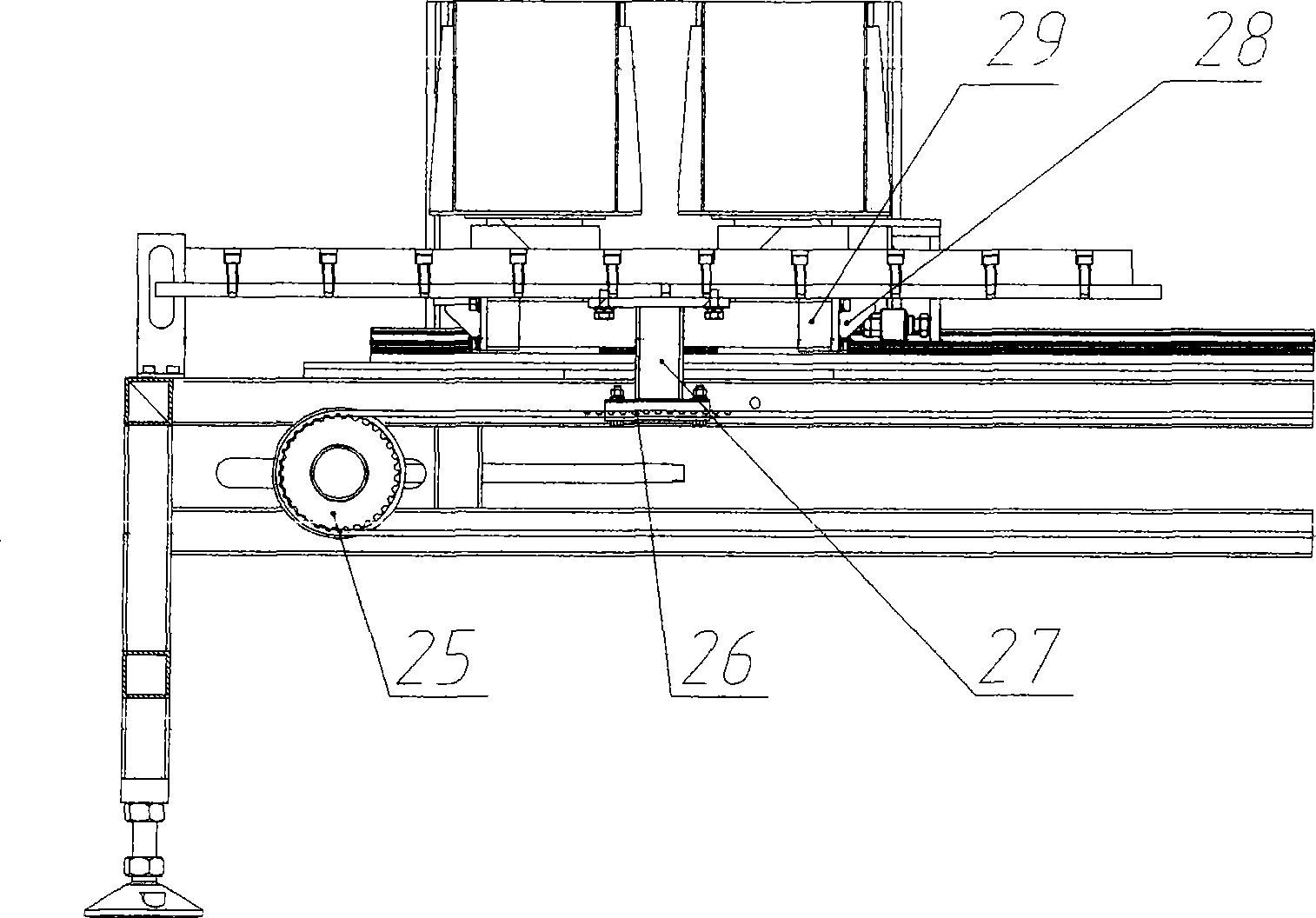

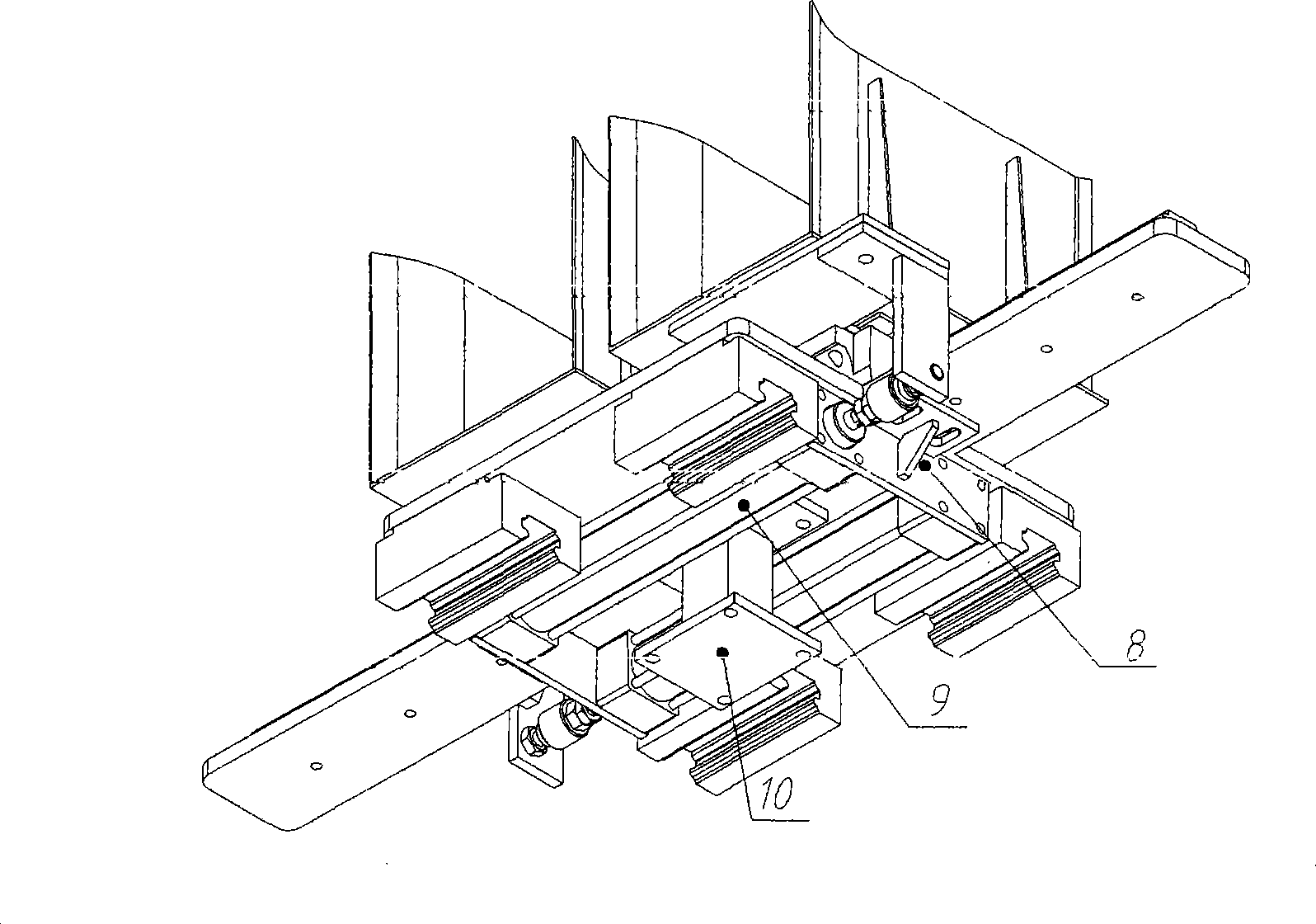

[0018] see Figure 1 to Figure 3 , the track conveyor of the present invention mainly consists of a driven wheel mounting plate 1, a wheel shaft 2 of a driven pulley, a tension screw 3, a universal foot 4, a tension seat 5, a clip 6, a frame 7, a long Guide rail mounting plate 8, driving wheel mounting plate 9, driving pulley 10, driven wheel at motor end 11, motor seat plate 12, driving wheel at motor end 13, reducer 14, motor 15, wheel shaft 16 of driving pulley, rotary encoder 17. Sensor 18, limit block 19, long linear guide rail 20, short guide rail mounting plate 21, L-shaped support 22, drug volume baffle plate 23, short linear guide rail 24, driven pulley 25, toothed plate 26, connection Block 27, cylinder mount 28 and cylinder 29 constitute.

[0019] The driven wheel mounting plate 1 is fixed on the rear end of the frame 7 with hexagonal bolts, the wheel shaft 2 of the driven pulley is fixed on the oblong hole of the driven wheel mounting plate 1, and the tension seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com