Fixer, surface-mount component using the fixer, and mounting structure using the fixer

A technology of a holder and a fixing part, which is applied in the field of the holder, can solve the problem of increasing the installation area, etc., and achieve the effects of preventing the decrease of the holding strength of the substrate, strengthening the bonding, and improving the holding strength of the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

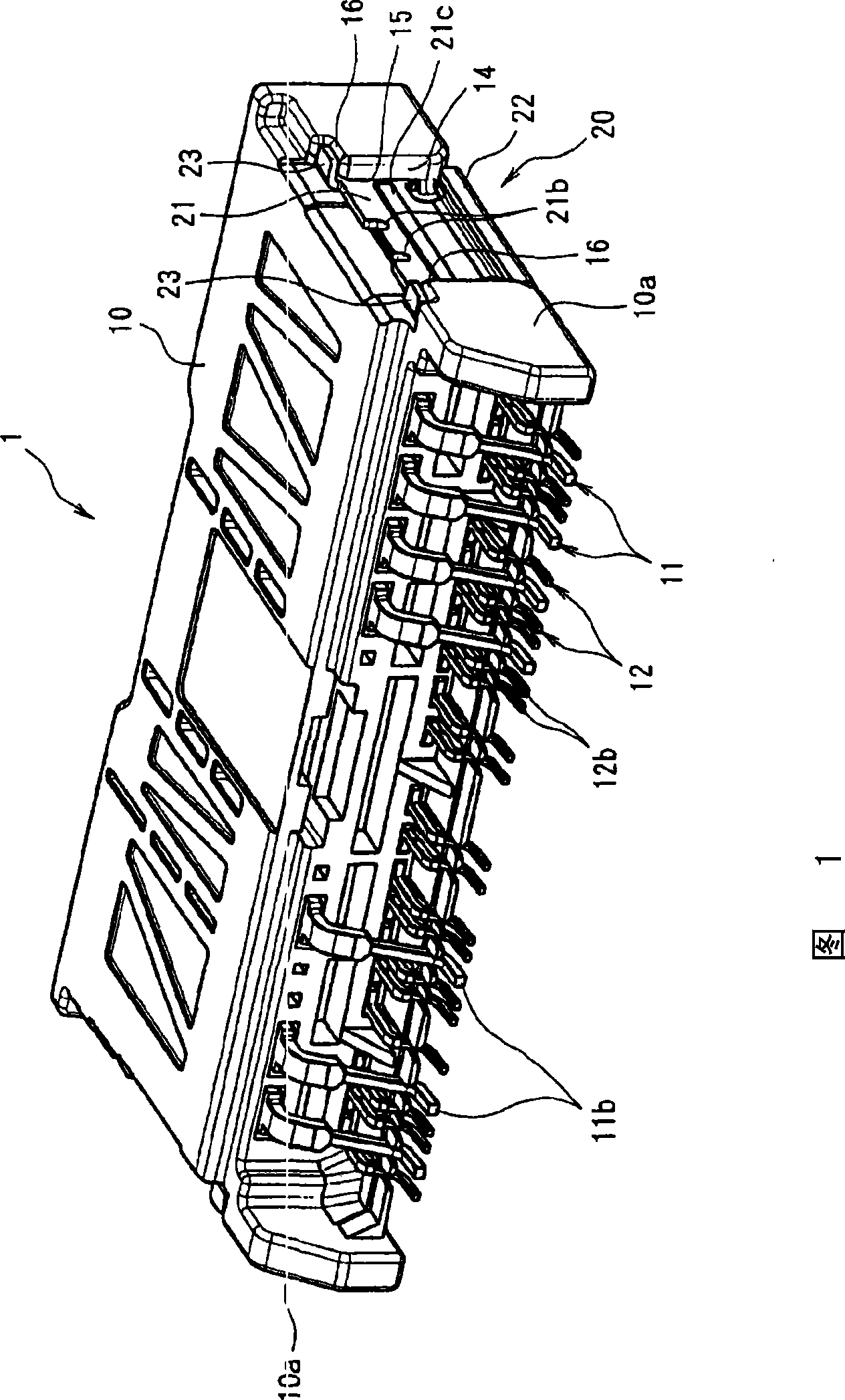

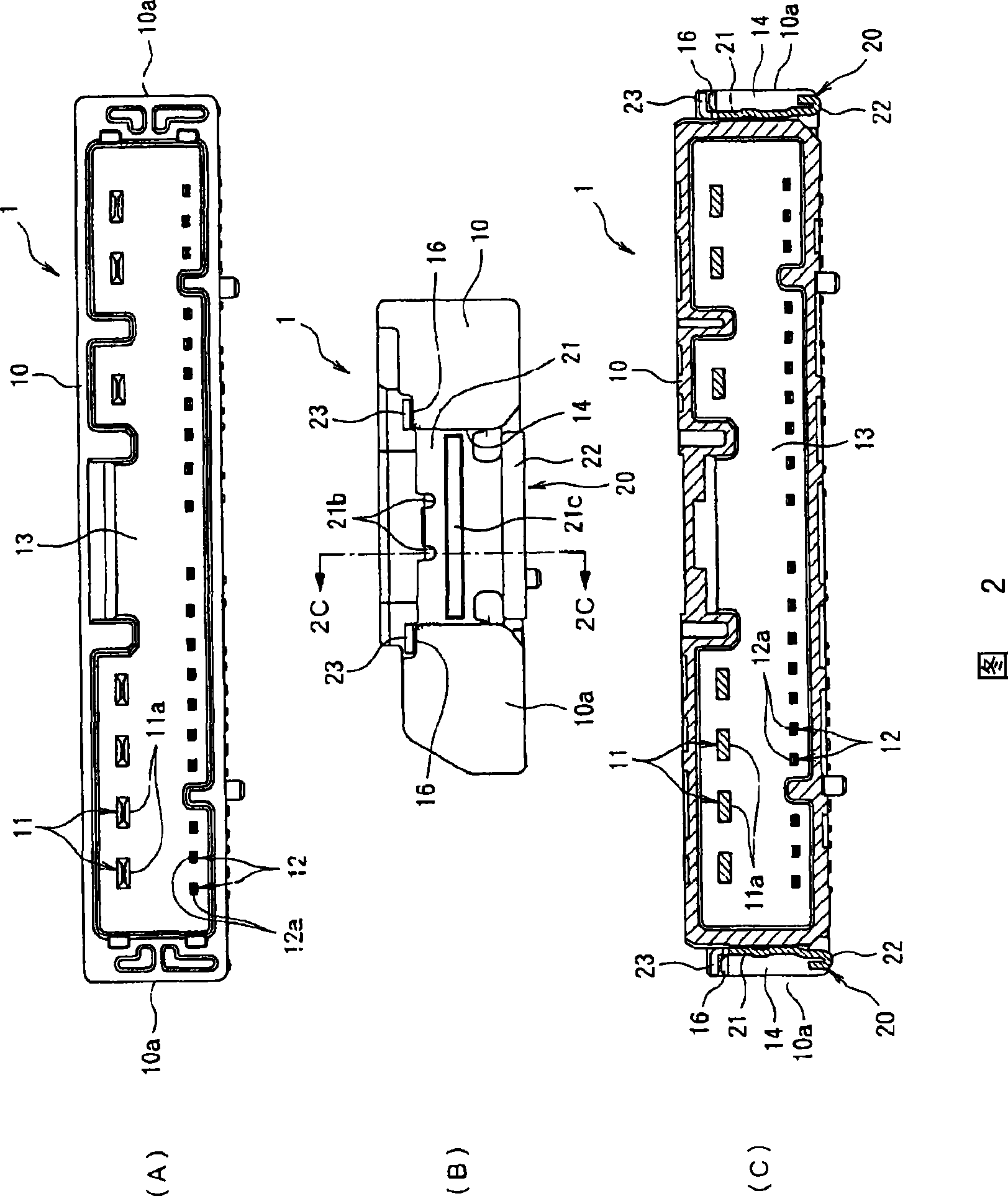

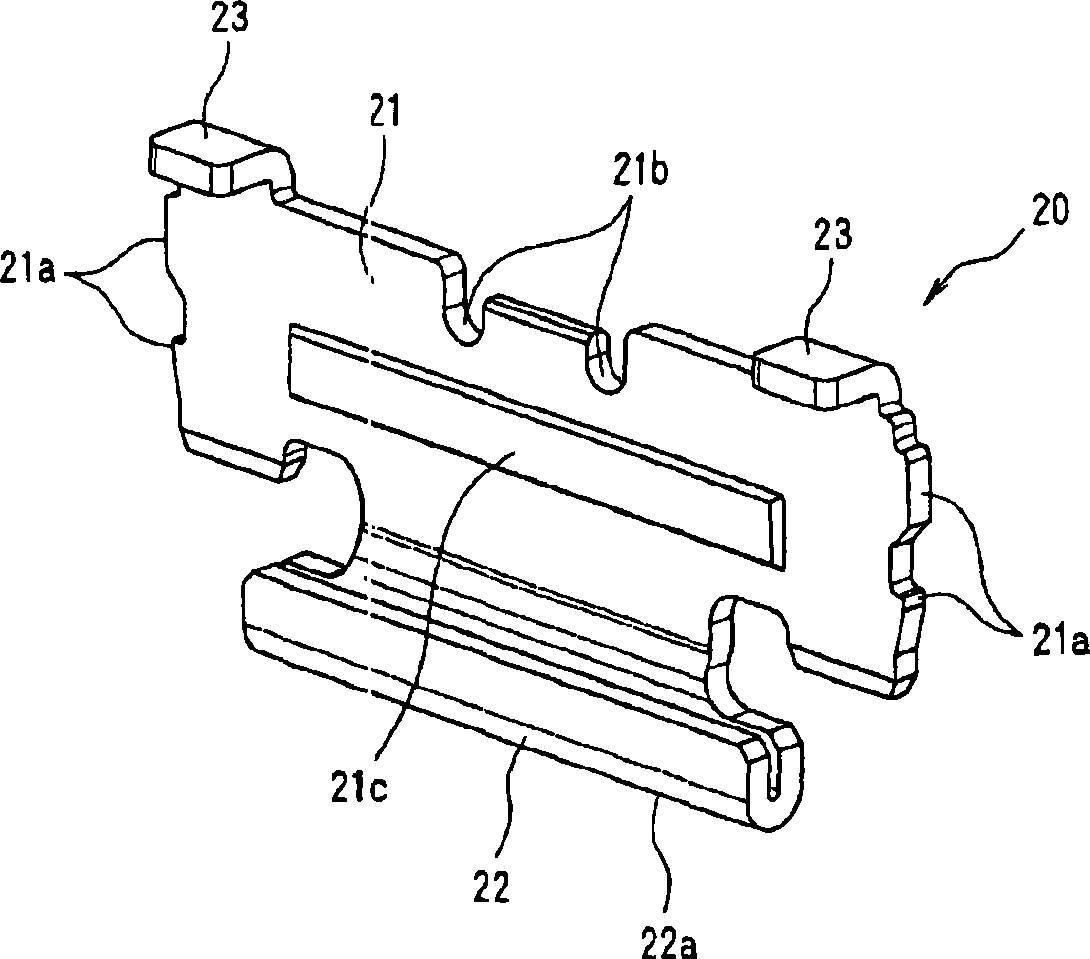

[0033] Embodiments of the present invention will be described with reference to the drawings. Fig. 1 is a perspective view of an electrical connector as a surface mount type component having a retainer of the present invention. Fig. 2 shows the electrical connector of Fig. 1, (A) is a front view, (B) is a left side view, (C) is a cross-sectional view along line 2C-2C in (B). image 3 It is a perspective view of the anchor of the present invention. Figure 4 shows image 3 (A) is a plan view, (B) is a front view, (C) is a bottom view, (D) is a right view, and (E) is a rear view. FIG. 5 is a perspective view of a state where the electrical connector of FIG. 1 is mounted on a circuit board.

[0034] The electrical connector (surface mount type component) 1 shown in Fig. 1 and Fig. 2 is mounted on the circuit board PCB, and has: an insulating housing (connection target) 10, which has a plurality of power contacts 11 and a plurality of Contacts 12 for signals; a pair of holders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com