Copper resource cyclic regeneration method in manufacture process

A cyclic regeneration and resource technology, which is applied in the field of copper resource recycling and regeneration in the process, can solve the problems of easily polluting the ion selective membrane of the potion and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

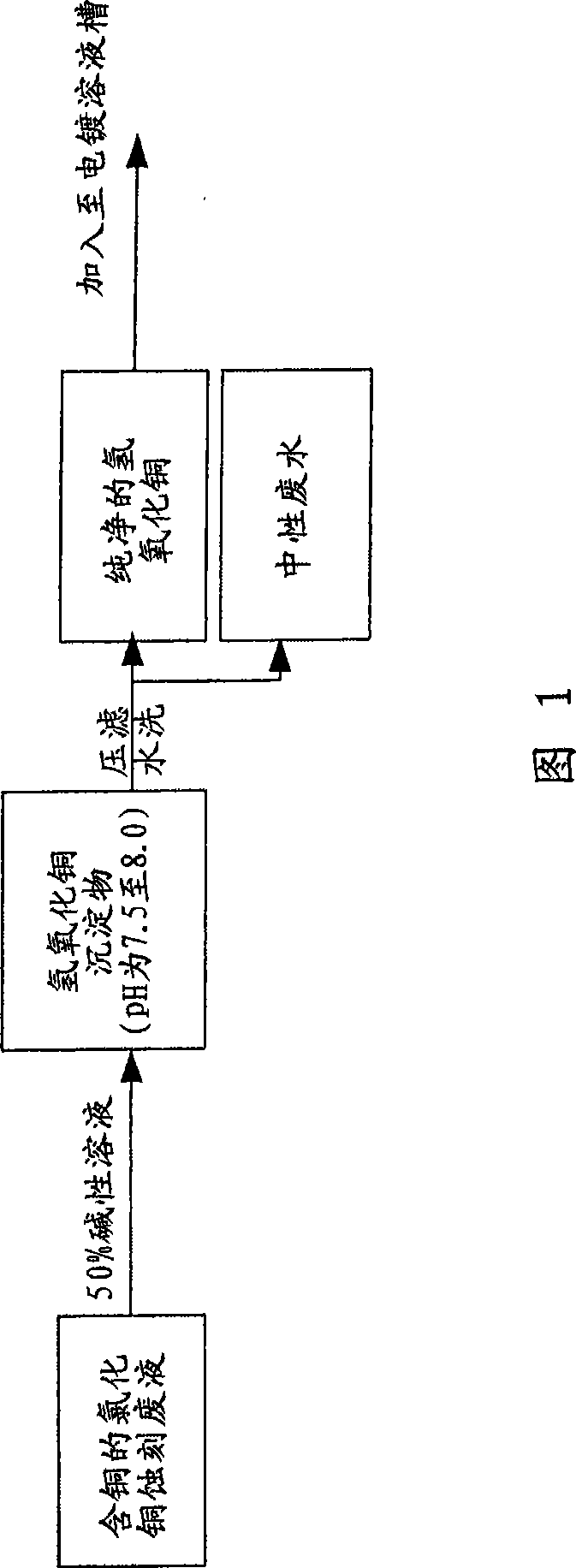

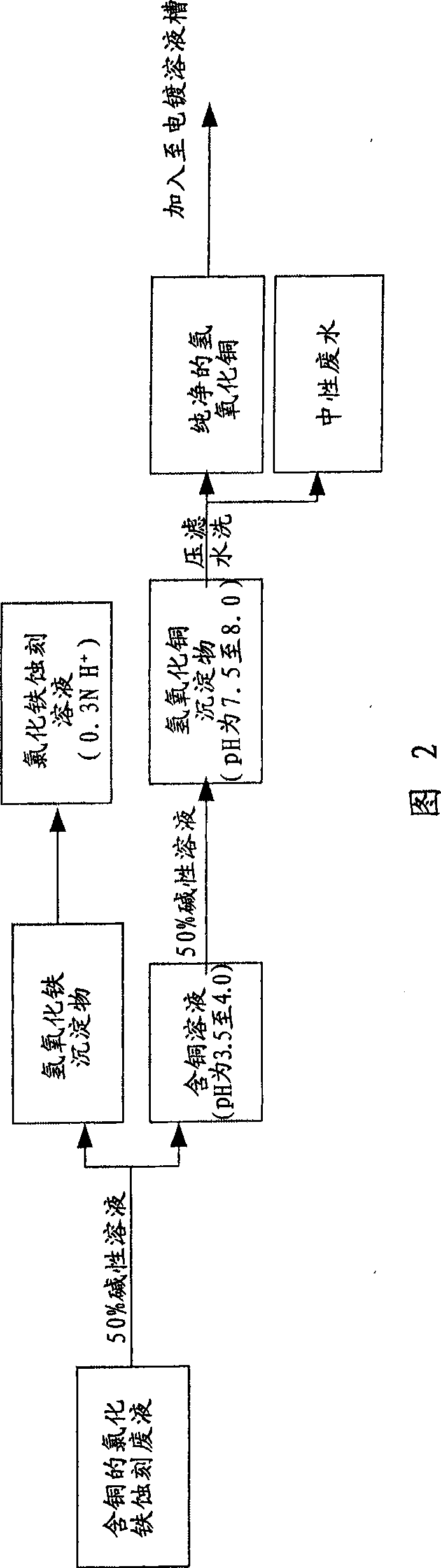

[0012] In the method for recycling and regenerating copper resources in the process of the present invention, when an acidic etching waste liquid containing copper is generated in the etching process, the method of the present invention mainly uses an alkaline solution to treat the acid etching waste liquid containing copper to form a copper-containing acid etching waste liquid for electroplating. The copper electroplating solution is put into the process of electroplating copper again.

[0013] After the above method is adopted, since the metal copper is no longer reduced from the etching waste liquid, it is no longer necessary to use the extraction solution or expensive ion selective membrane which is easy to contaminate the potion, and also does not need to use high-temperature molten copper and very power-consuming equipment. Of course, there is no need to outsource treatment for electro-purification, and there are no problems that may arise in the process of transporting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com