Optical micro-control system and operation control method thereof

A manipulation system and optical technology, applied in the field of optical micro manipulation systems, can solve the problems of lack of timely correction, inadequate operation, complicated correspondence, etc., so as to achieve functional expansion, extension of application scope, and good flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The following part of this example describes an optical micromanipulation system:

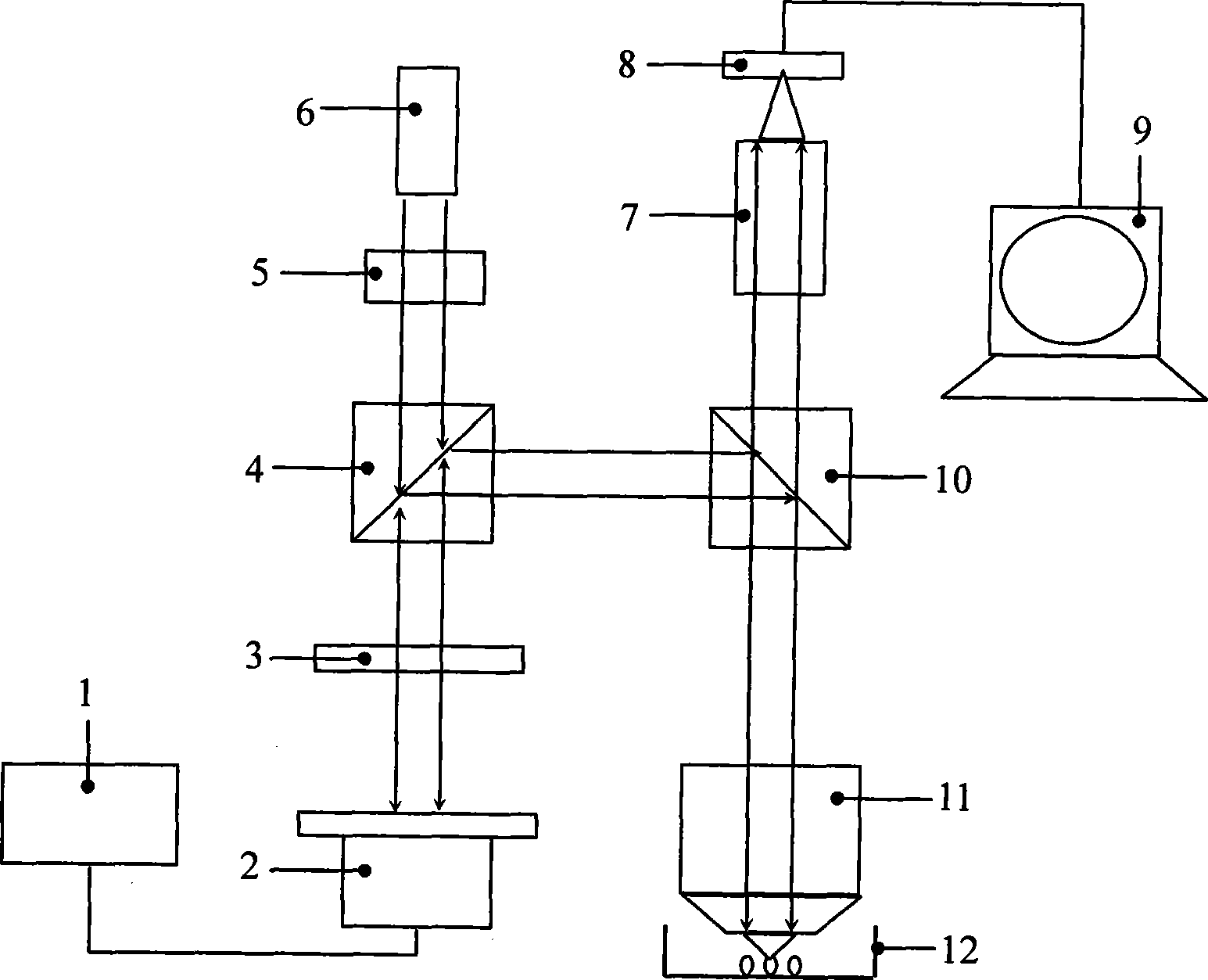

[0024] Such as figure 1 As shown, the optical micro-manipulation system includes a light source 6, a beam-containing device 5, a polarizing beam splitter 4, a quarter-wave plate 3, a reflective phase adjustment device 2, a spectral beam splitter 10, an imaging mirror group 7, a CMOS device 8, The monitor 9 and the objective lens 11 are provided with a beam-containing device 5, a polarizing beam splitter 4, a quarter-wave plate 3 and a reflective phase adjustment device 2 in sequence directly below the light source 6, and the reflective phase adjustment device 2 is controlled by a controller 1. control, the reflection path of the polarization beam splitter 4 is provided with a spectral beam splitter 10, the objective lens 11 is arranged directly below the spectral beam splitter 10, the imaging mirror group 7 and the CMOS device 8 are arranged directly above the spectral beam splitter 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com