Method for detecting photolithography equipment exhaust system and judging product CPK

An exhaust system and product technology, applied in the direction of microlithography exposure equipment, photolithography exposure equipment, etc., can solve the problems of wasting manpower, low pass rate, and reducing machine work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

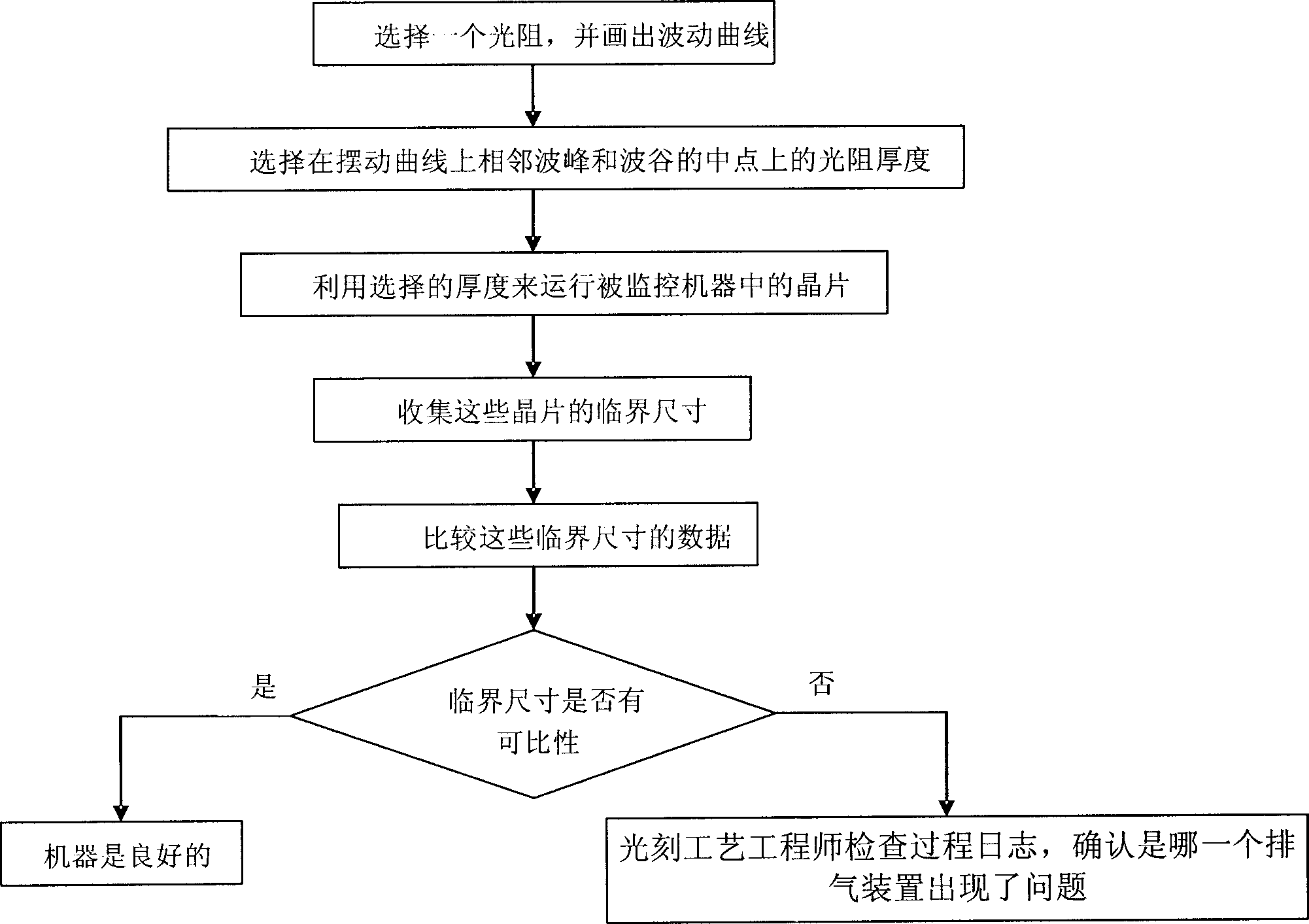

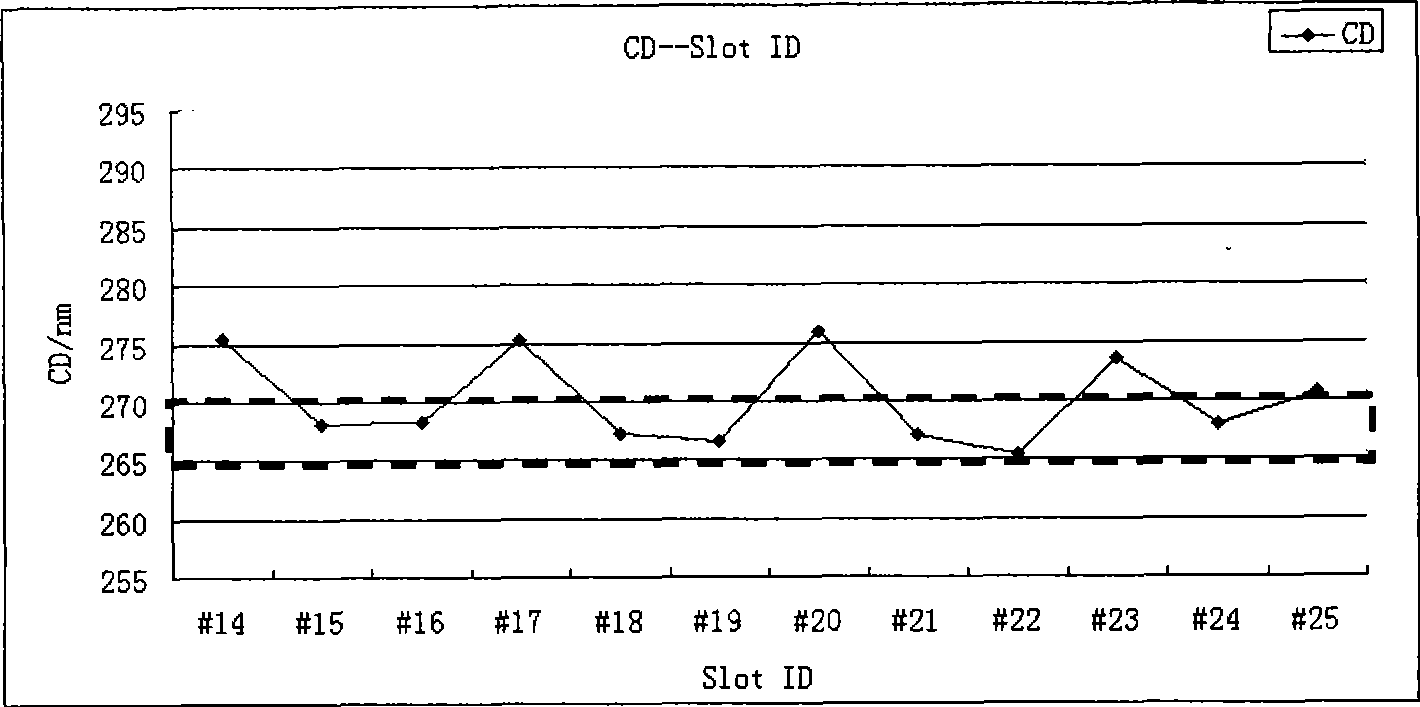

[0028] The present invention provides a new method for detecting the exhaust system of a machine in the field of lithography, and its specific details are described as follows:

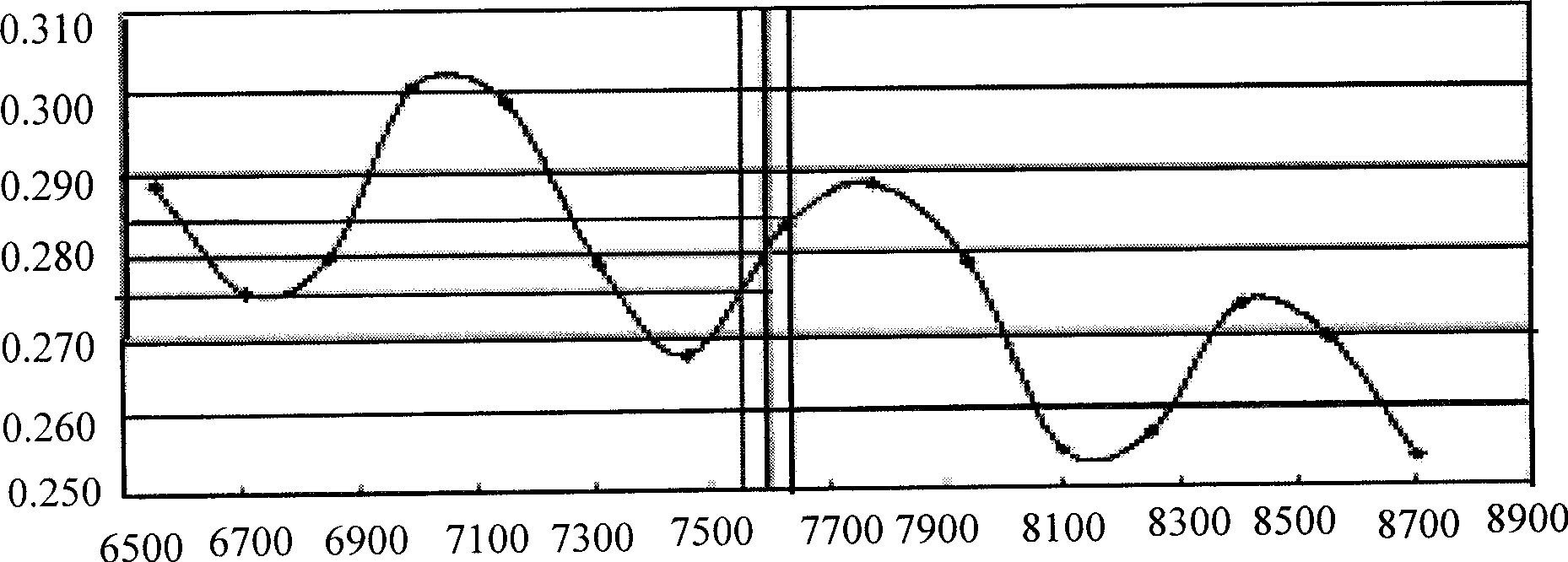

[0029] The photolithography process uses an exposure machine and an orbital machine. We know that the exhaust system of the machine is a factor affecting the thickness of the photoresist, and the rocking curve shows that the feature size will change with the thickness of the photoresist. In order to accurately detect the current status of the exhaust system, photolithography process engineers usually select a point on the swing curve for detection. At this point, when the thickness of the photoresist changes slightly, the feature size of the product will change. This change is magnified. So this point is sensitive enough to detect the exhaust system.

[0030] When a lithography process engineer selects a photoresist and draws a swing curve, he / she can arbitrarily select a point on the swing curve an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com