Plasma processing apparatus

A technology for plasma and processing containers, which is applied in the fields of plasma, semiconductor/solid-state device manufacturing, gaseous chemical plating, etc., and can solve problems such as the problem of particle electron density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

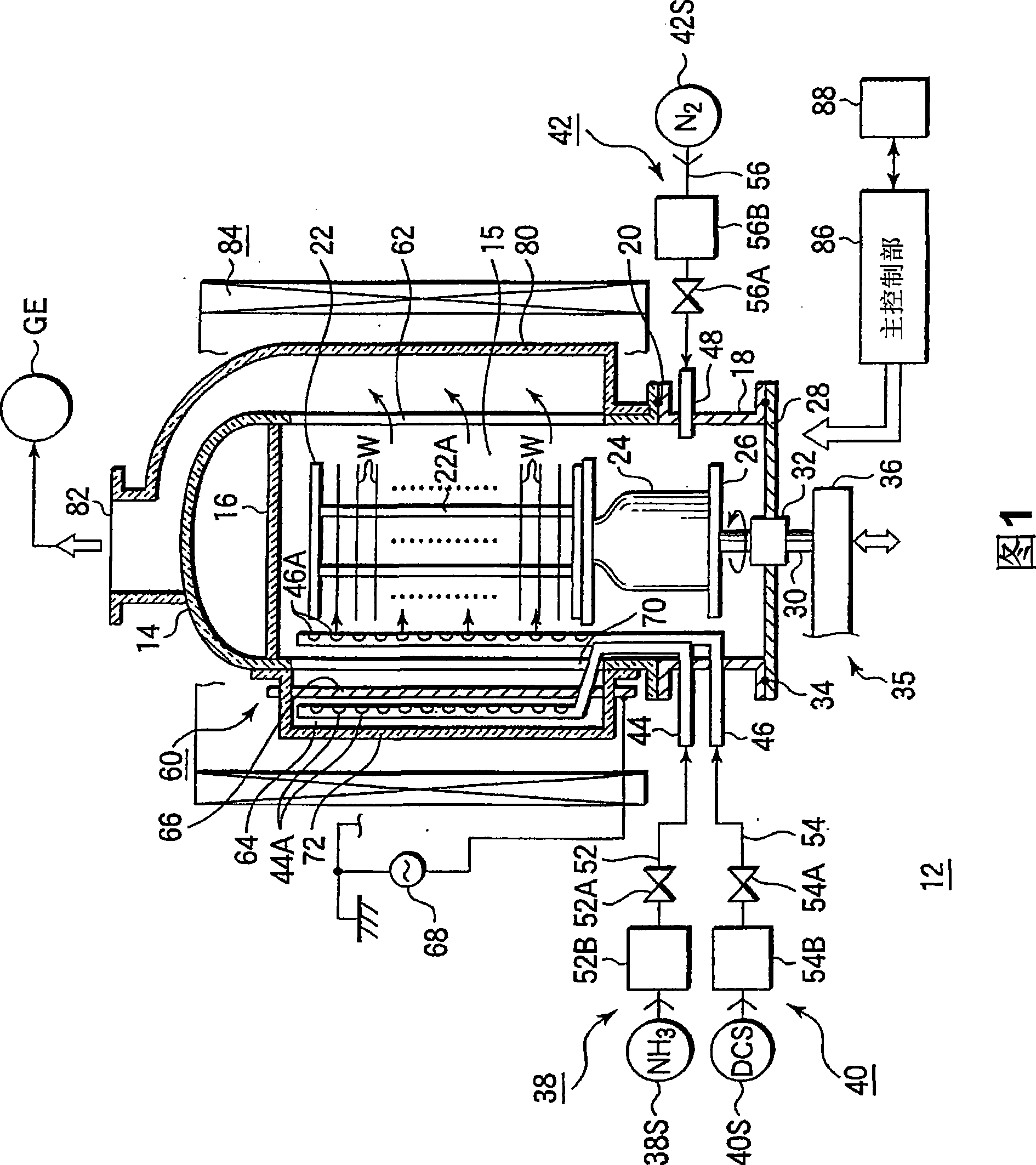

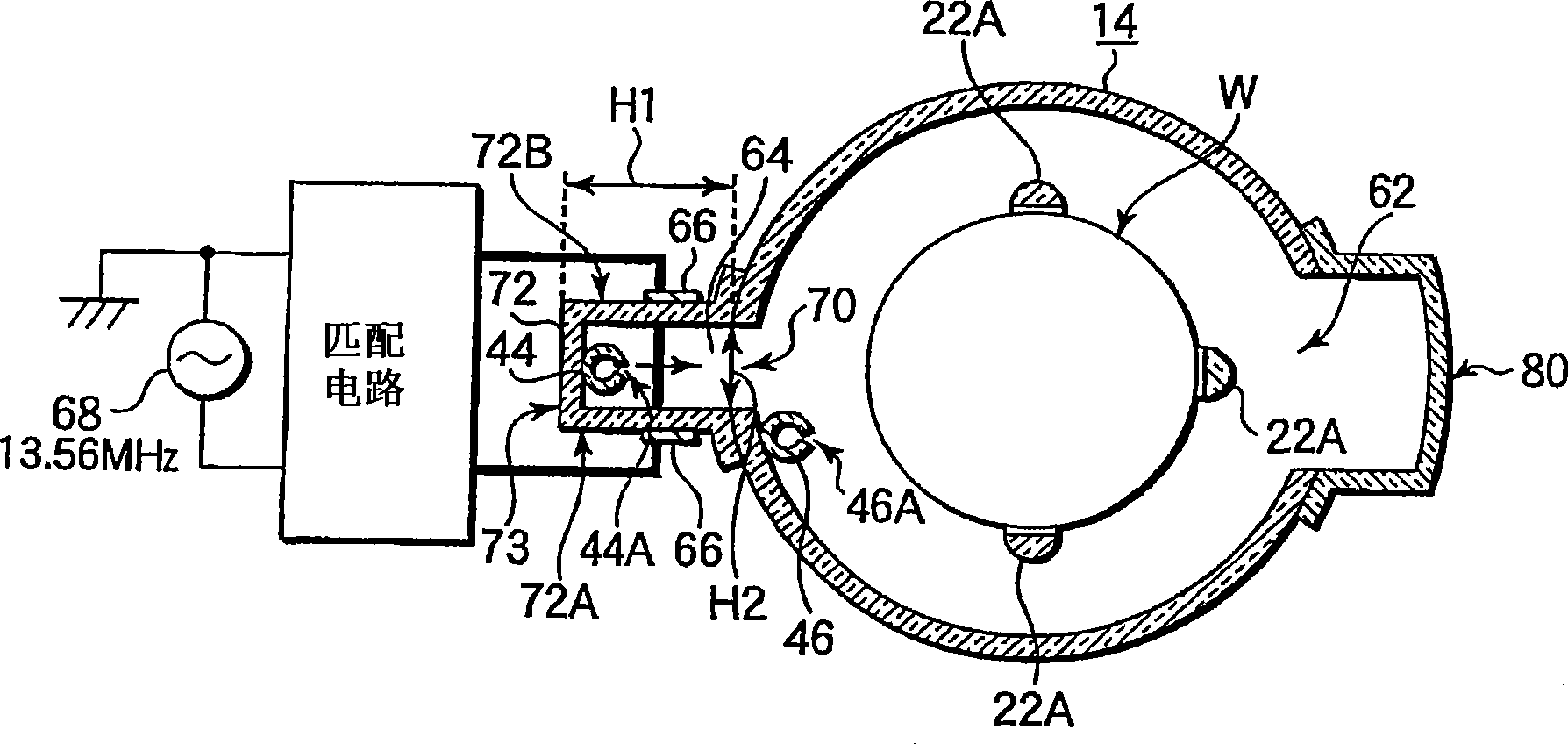

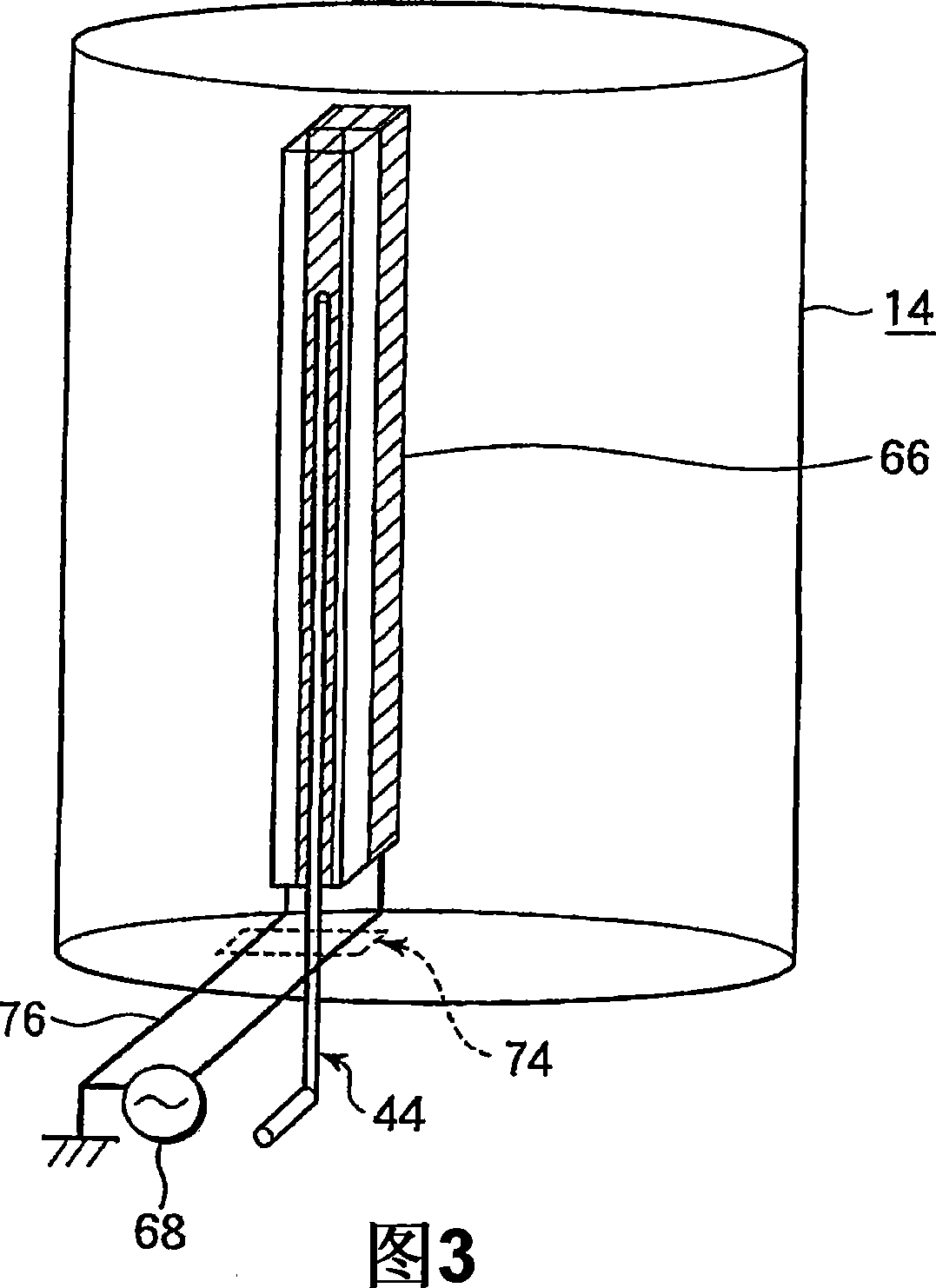

[0043] FIG. 1 is a vertical front view showing a vertical plasma processing apparatus according to a first embodiment of the present invention. figure 2 It is a cross-sectional plan view showing a part of the apparatus shown in FIG. 1 (the heater is omitted). Fig. 3 is a schematic perspective view mainly showing ICP electrodes of the device shown in Fig. 1 . Figure 4 is a block diagram showing the circuit including ICP electrodes. This plasma processing apparatus 12 includes a first processing gas capable of selectively supplying a gas containing dichlorosilane (DCS) as a silane-based gas and a gas containing ammonia (NH 3 ) in the processing area of the second processing gas. The plasma processing apparatus 12 is configured such that, in such a processing region, NH 3 The gas is activated to form a silicon nitride film on the object to be processed.

[0044] The plasma processing apparatus 12 has a topped cylindrical processing container 14 with an open lower end, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com