Lithium ion battery cathode sheet and preparation method thereof, and lithium ion battery

A technology of lithium-ion batteries and negative electrodes, which is applied in the direction of electrode manufacturing, secondary batteries, active material electrodes, etc., can solve the problems of negative electrode active materials falling off and breaking, and achieve the ability to improve intercalation/delithiation, contact improvement, and cycle The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment is used to illustrate the lithium ion battery negative electrode sheet provided by the present invention and the lithium ion battery containing the negative electrode sheet.

[0046] (1) Preparation of positive electrode sheet

[0047] 100 parts by weight of LiFePO with a particle diameter of 0.5 microns 4 (produced by Tianjin Leading Company), 5 parts by weight of binder polyvinylidene fluoride (PVDF), 8 parts by weight of conductive agent acetylene black join in 80 parts by weight of N-methylpyrrolidone (NMP), then stir in vacuum mixer A cathode active material slurry was obtained. The obtained cathode active material slurry is coated on a wide aluminum foil with a width of 400 mm and a thickness of 20 microns, and the thickness of both sides is 150 microns; then, vacuum-dry at 100 ° C, and cut into 43.5 mm x 31 mm positive plate A1.

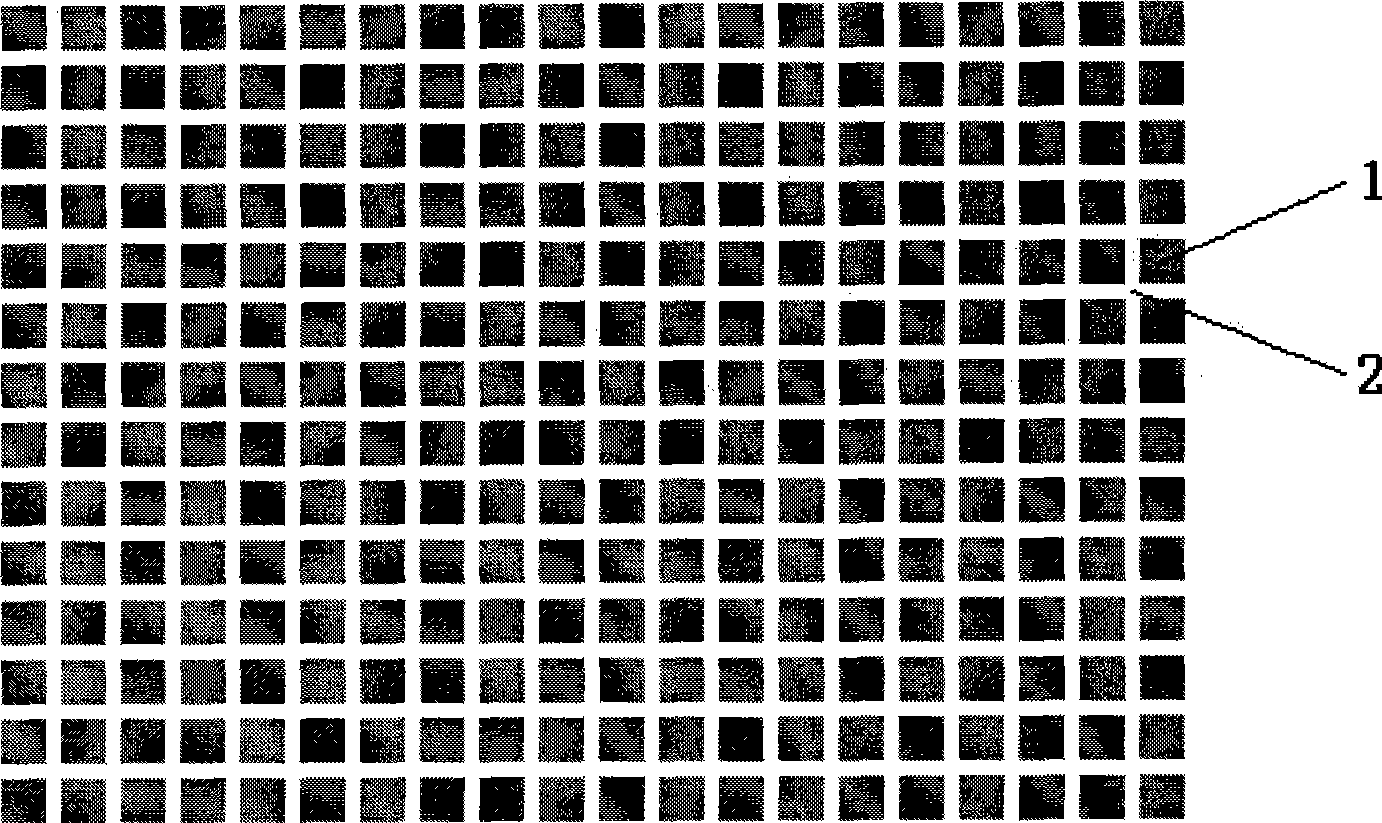

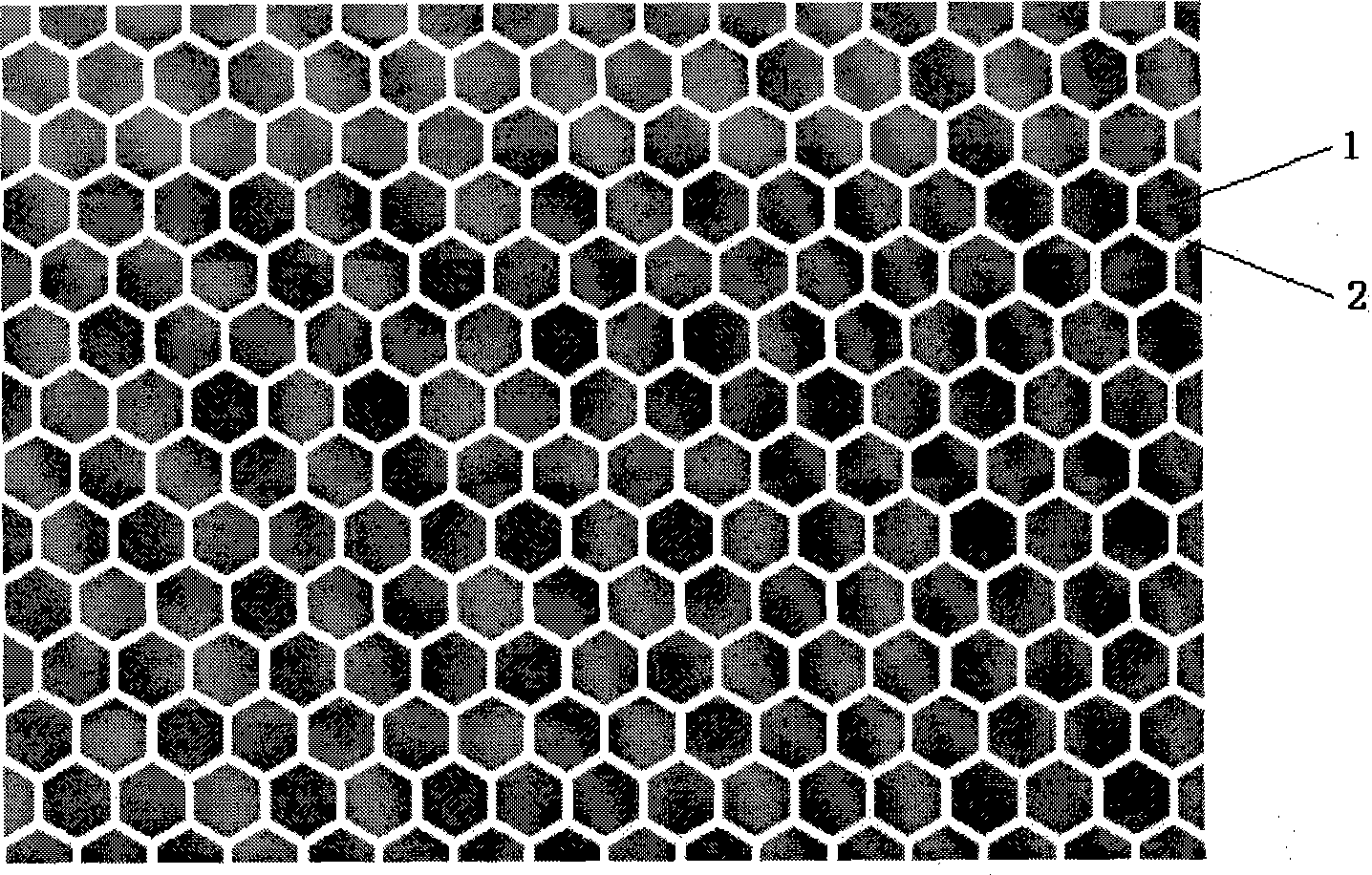

[0048] (2) Preparation of negative electrode sheet

[0049] Weigh 100 parts by weight of N-methylpyrrolidone (NMP)...

Embodiment 2

[0056] This embodiment is used to illustrate the lithium ion battery negative electrode sheet provided by the present invention and the lithium ion battery containing the negative electrode sheet.

[0057] (1) Preparation of positive electrode sheet

[0058] 100 parts by weight of LiFePO with a particle diameter of 0.5 microns 4 (produced by Tianjin Leading Company), 5 parts by weight of binder polyvinylidene fluoride (PVDF), 8 parts by weight of conductive agent acetylene black join in 80 parts by weight of N-methylpyrrolidone (NMP), then stir in vacuum mixer A cathode active material slurry was obtained. The obtained cathode active material slurry is coated on a wide aluminum foil with a width of 400 mm and a thickness of 20 microns, and the thickness of both sides is 155 microns; then, it is vacuum-dried at 100 ° C and cut into 43.5 mm x 31 mm positive sheet A2.

[0059] (2) Preparation of negative electrode sheet

[0060] The natural graphite of 100 parts by weight of ...

Embodiment 3-4

[0064] Cycle performance test

[0065] The lithium-ion batteries D1-D2 prepared in the above-mentioned Examples 1-2 were subjected to a cycle performance test. The specific steps were to charge to 3.8 volts with a current of 1 CmA, and charge at a constant voltage after the voltage rose to 3.8 volts, with a cut-off current of 0.05 CmA , rest for 5 minutes; the battery is discharged to 2.0 volts with 1CmA current, and rest for 5 minutes. Repeat the above steps 100 times to obtain the capacity of the battery after 100 cycles of 1CmA current discharge to 2.0 volts, and calculate the capacity maintenance rate before and after the cycle. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com